Executive Overview

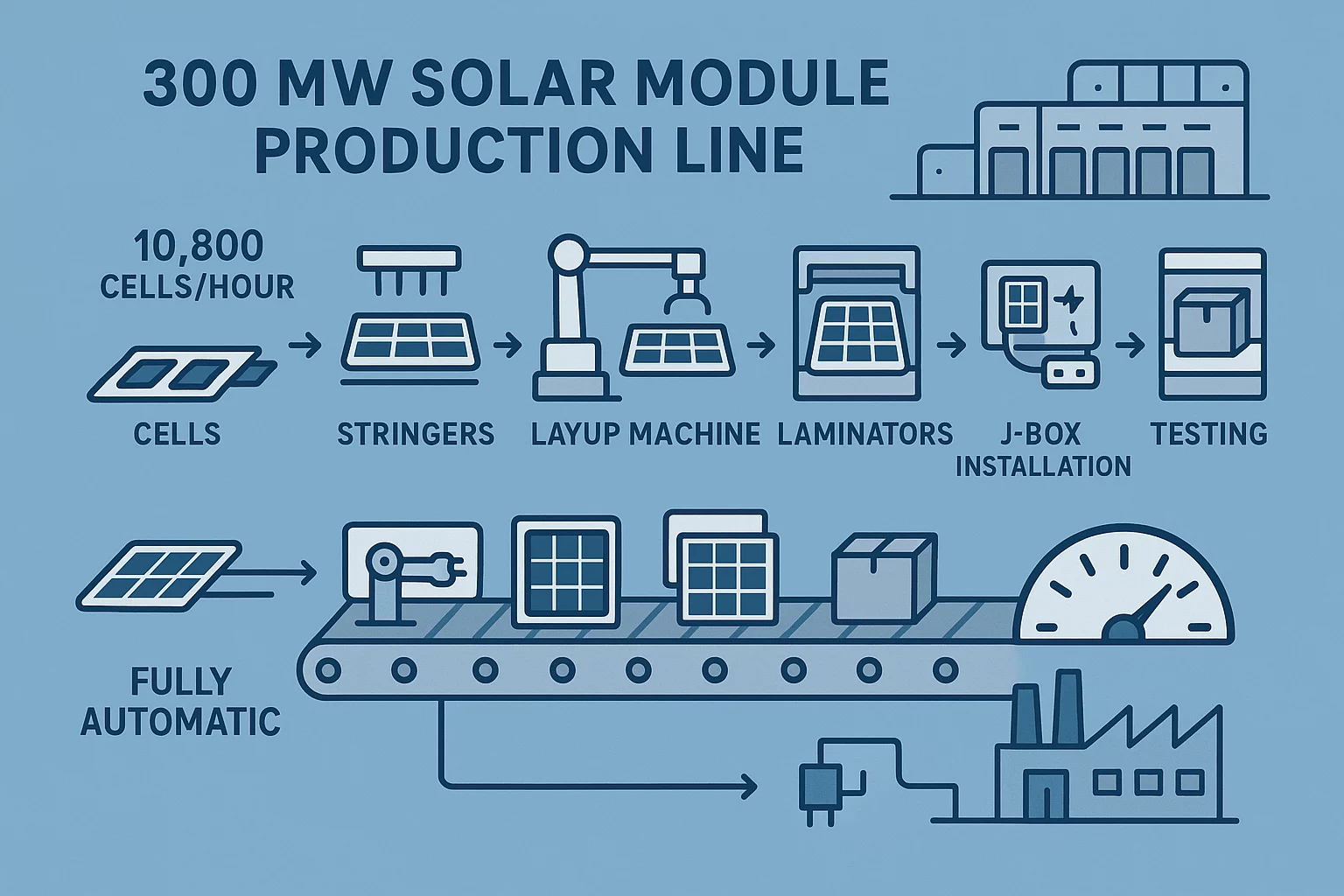

Stepping into industrial-scale solar manufacturing means a significant leap in capacity, automation, and efficiency. A 300 MW production line embodies this transition, moving beyond typical large-scale operations into a realm of high throughput and regional market dominance.

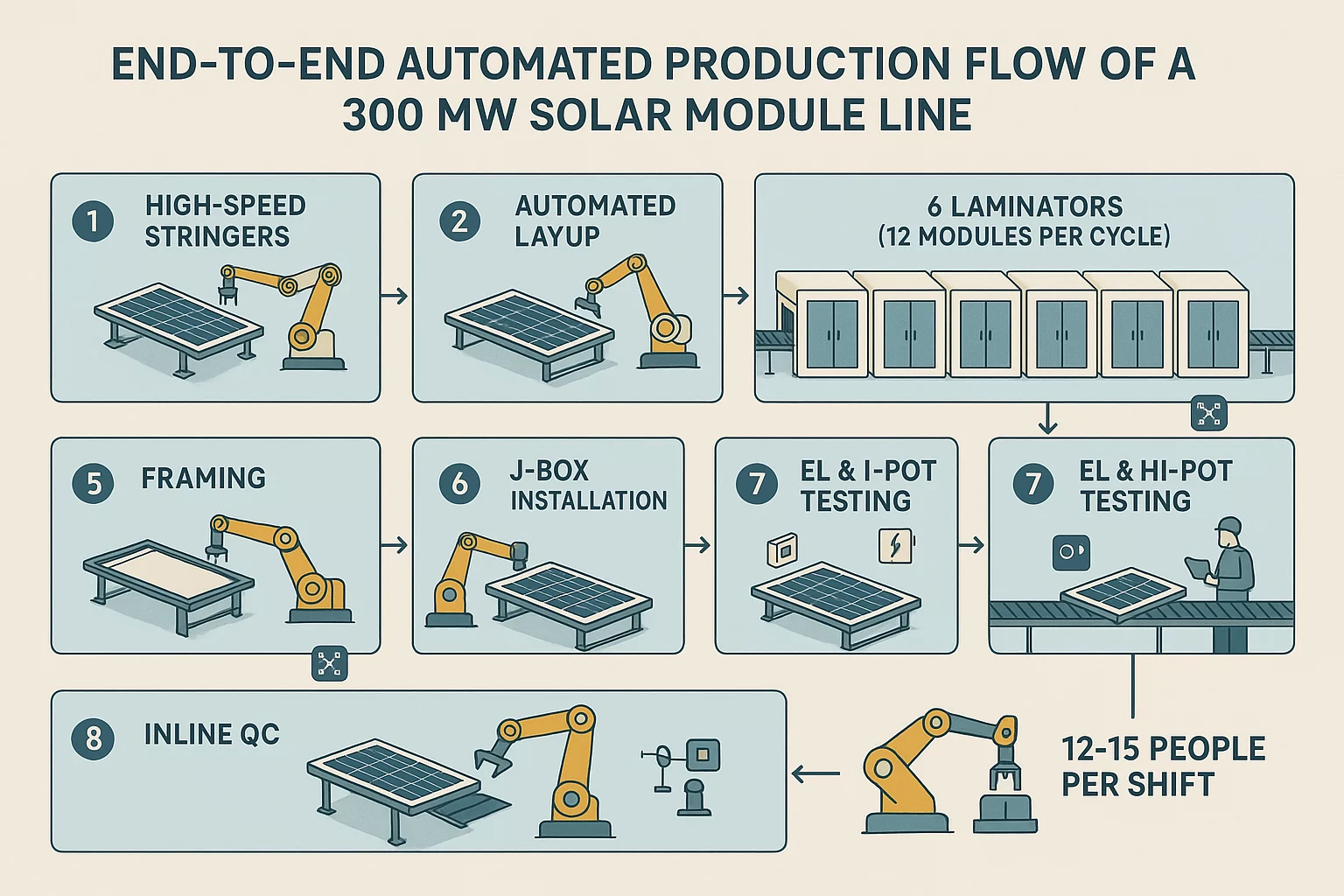

Engineered for substantial output, this fully automated line processes up to 10,800 cells per hour. With six high-capacity laminators operating in parallel, the system laminates 12 modules simultaneously in a single cycle. This configuration is ideal for established manufacturers looking to scale aggressively and for investors aiming to supply utility-scale projects directly.

The technical details below are based on official J.v.G. technology GmbH commercial offers, providing a solid foundation for your project planning.

Technical Specifications

The 300 MW line is designed for high-volume, reliable production of large-format solar modules, meeting the demands of the most competitive global markets.

Technical Specifications Table

- Cell Throughput: 10,800 cells/hour

- Modules per Lamination Cycle: 12

- Typical Capacity: approx. 240 MW/year (at 85% uptime)

- Maximum Capacity: 300 MW/year

- Maximum Panel Size: 2,400 x 1,400 mm

- Supported Cell Types: M2-M12, TOPCon, HJT

- Busbars: Up to 20

- Automation Level: Fully Automatic Line

- Delivery Time: 6-9 months from down payment

- Payment Terms: 30% down, 60% pre-shipment, 5% install, 5% acceptance

What’s Included: Bill of Equipment Snapshot

A turnkey 300 MW line is a fully integrated system where every machine works in seamless concert. Your factory comes equipped with a complete set of high-performance machinery, including:

- Multiple High-Speed Stringers: To achieve a combined throughput of 10,800 cells per hour and feed the line continuously.

- Fully Automated Layup System: Precisely assembles the glass, EVA, cell matrix, and backsheet with minimal human intervention.

- Automatic Bussing Stations: Connect cell strings accurately and reliably.

- Six High-Capacity Laminators: The core of the line, processing 12 modules per cycle to reach industrial-scale volume.

- Automatic Framing Station: Applies and secures the aluminum frame to the laminate.

- Automatic J-Box Installation: Attaches and seals the junction box with precision.

- Integrated EL & Hi-Pot Testers: Perform critical quality checks inline to detect micro-cracks and ensure electrical safety.

- Inline QC and MES Integration: A Manufacturing Execution System (MES) tracks every module, monitors processes, and ensures full traceability.

- A+A+A+ Sun Simulator (Flasher): Classifies finished modules according to their exact power output.

Line Layout & Operations

The entire production process is a seamless, end-to-end automated flow. From cell stringing to the final sorting of finished modules, the system minimizes manual handling, reducing the risk of error and maximizing consistent output.

The high level of automation keeps staffing requirements lean. A typical shift requires only 12-15 trained operators and technicians to oversee the line, manage material supply, and respond to system alerts.

The integrated MES provides managers with real-time dashboards for monitoring production yields, identifying bottlenecks, and enforcing strict quality control at every stage.

Investment, Operating Expenses (OPEX), and ROI

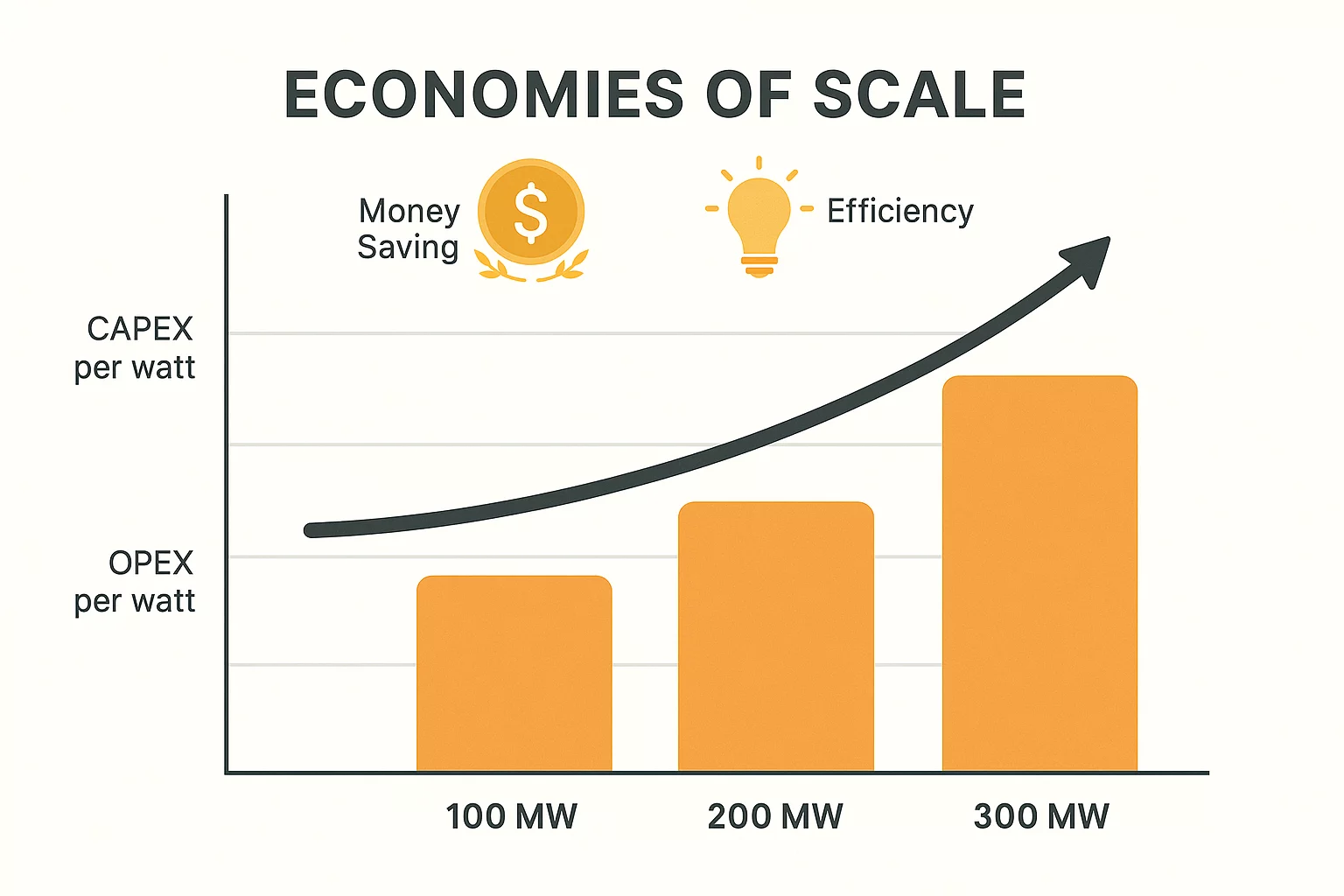

While the initial capital expenditure (CAPEX) for a 300 MW line is higher than for smaller capacities, the investment unlocks powerful economies of scale. The key financial benefit is a substantially lower cost per watt, a critical advantage when competing for large commercial and utility-scale projects.

It’s important to distinguish between typical and maximum output. While the line has a maximum capacity of 300 MW per year, a factory running at a standard 85% uptime will produce approximately 240 MW. Reaching peak capacity requires optimized shift schedules and operational excellence. This combination of a lean cost structure and high-volume capability enables a faster return on investment in competitive energy markets.

Request a Tailored Offer

Use Cases & Ideal Buyers

A 300 MW production line is a strategic asset for a specific class of industrial players:

- Established Module Manufacturers: Companies ready to scale up production to dominate their regional market and compete on an international level.

- EPCs and Independent Power Producers (IPPs): Businesses seeking vertical integration to secure their module supply chain and control costs for large commercial and utility-scale solar farms.

- Strategic Investors: Entrepreneurs and investment groups aiming to build a significant industrial presence with high throughput and a competitive cost-per-watt advantage.

Why Choose J.v.G. as Your Partner

Building a factory is about more than just equipment; it’s about choosing a partner with the experience and integrity to ensure your success.

As a founder-led, family-run company, we have built our reputation on over 25 years of integrity and hands-on expertise. We do not offer one-size-fits-all solutions. Instead, we provide tailored technology that is modular and scalable to your specific market and goals. For projects in challenging environments, our specialized DESERT & TROPIC Technology ensures long-term module reliability in extreme heat and humidity.

We guide your project with our proven 6-Phase Process—a comprehensive roadmap that takes you from initial planning and financing to full-scale operation and beyond.

Talk to our founders

Upgrade Path to 400 MW and Beyond

A 300 MW line isn’t a final destination but a powerful platform for future growth, with a layout designed for straightforward expansion. The most direct path to scaling involves adding more laminators and enhancing logistics automation to handle the increased material flow. This modular approach protects your initial investment and allows you to grow your capacity in step with market demand.

For a deeper understanding of how this line compares to other capacities, see our guides on the 200 MW line and the 400 MW line.

300 MW vs 400 MW Upgrade Comparison

| Feature | 300 MW Line | 400 MW Upgrade |

|---|---|---|

| Laminators | 6 units | Add 2-3 more units |

| Stringers | Additional units may be needed | |

| Logistics | Semi-automated | Fully automated transfer systems |

| Footprint | Increases moderately |

Frequently Asked Questions

(FAQ schema JSON-LD placeholder)

What is the required factory footprint and ceiling height?

A 300 MW line typically requires a production hall of at least 10,000 m² (approx. 110,000 sq ft) with a minimum clear ceiling height of 6-8 meters to accommodate machinery and overhead gantries.

How many staff are needed per shift?

Thanks to its high level of automation, a standard shift requires only a team of 12-15 people, including line operators, quality control technicians, and maintenance staff.

What are the main utility requirements?

The primary utility needs are electrical power (typically in the range of 1.5-2.0 MW), a stable supply of compressed dry air, and a process cooling water system for the laminators.

What is included for warranty, training, and spare parts?

Our turnkey solutions include a comprehensive warranty on all equipment, extensive onsite training for your operational and maintenance teams, and a recommended spare parts package to ensure maximum uptime.

What does the delivery and acceptance process look like?

The timeline from down payment to delivery is typically 6-9 months. Following installation and commissioning, final acceptance occurs once the line meets all contractually agreed performance and quality benchmarks.

How can this line be upgraded to 400 MW?

The line can be expanded to 400 MW by adding more laminators to increase throughput, potentially upgrading stringer capacity, and implementing more advanced automated logistics between process steps.

Take the Next Step

Ready to explore the financial and technical details of your own 300 MW factory? We can provide a comprehensive, confidential offer tailored to your project.

Request a Tailored Offer

Download Sample Offer (PDF)