400 MW Solar Module Production Line: A Guide to Setup, Automation, and Investment

For investors and industrial leaders targeting large-scale energy markets, the goal extends beyond simply producing solar modules. It’s about establishing a manufacturing operation with the scale, efficiency, and quality to meet regional and international demand. A 400 MW production line represents this level of ambition—a fully automated facility engineered for high throughput and long-term performance.

This guide provides a clear overview of a 400 MW solar module factory, detailing the technical specifications, equipment, and strategic considerations for such an investment. The specifications outlined here are drawn directly from official J.v.G. turnkey solutions, reflecting our commitment to transparency and proven engineering.

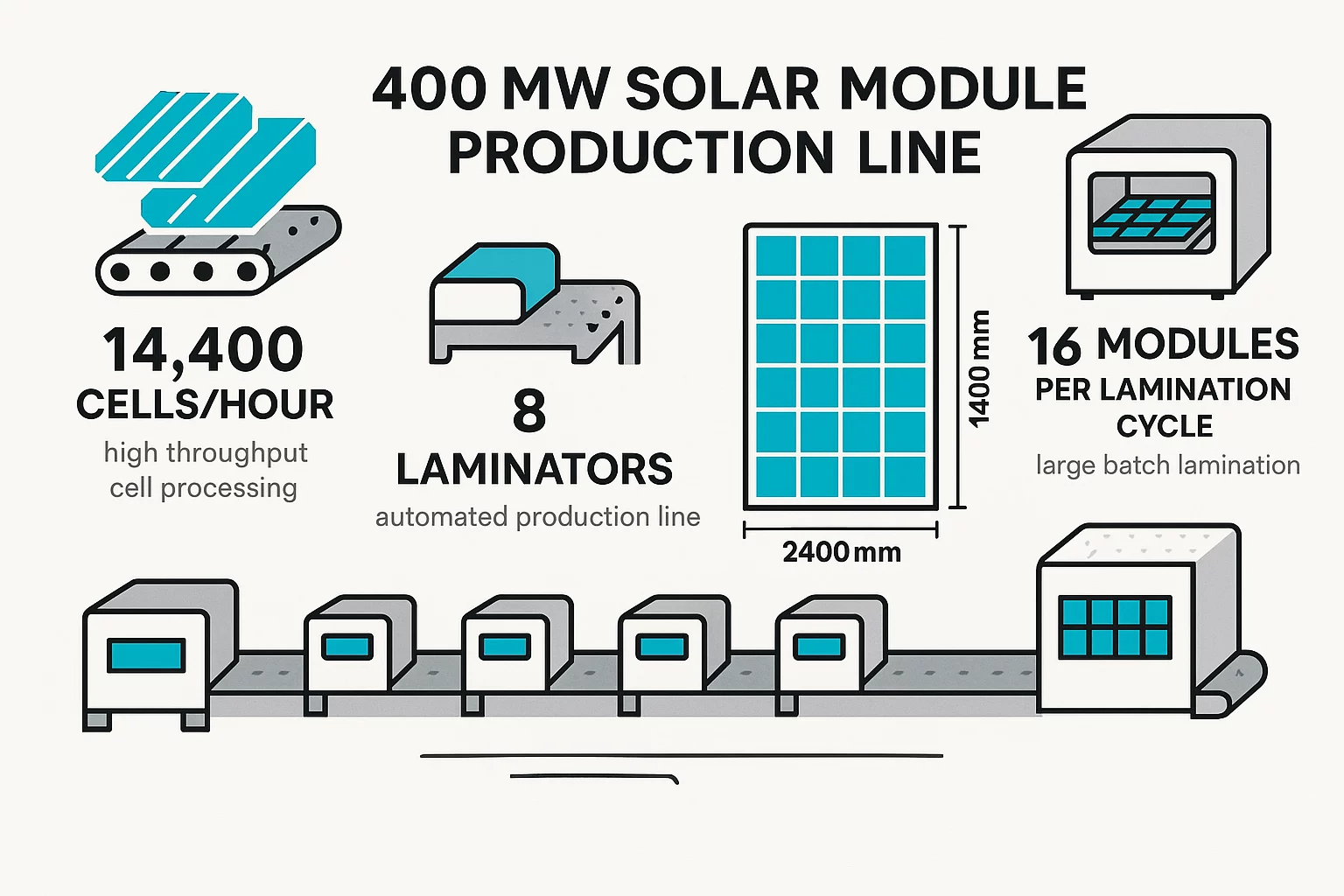

With a throughput of 14,400 cells per hour and a capacity of 16 modules per lamination cycle across eight laminators, this setup is designed for serious industrial production.

Technical Specifications

Performance data is the foundation of any manufacturing plant. These figures define its production capacity, operational scope, and technological capabilities. Below are the core specifications for a J.v.G. 400 MW turnkey line.

- Cells per Hour: 14,400

- Modules per Lamination Cycle: 16

- Typical Capacity: approx. 320 MW per year (based on standard operating schedules)

- Maximum Capacity: 400 MW per year

- Maximum Panel Size: 2,400 x 1,400 mm

- Supported Cell Types: M2–M12, TOPCon, HJT

- Busbars: Up to 20

- Automation Level: Fully Automatic Line

- Delivery Time: 6–9 months from contract signing

- Standard Payment Terms: 30% down payment, 60% before shipment, 5% upon installation, 5% upon final acceptance

Technical Specifications Summary

- Throughput (Cells/Hour): 14,400 cph

- Max Annual Capacity: 400 MW

- Typical Annual Capacity: approx. 320 MW

- Max Module Dimensions: 2,400 x 1,400 mm

- Cell Technology: M2–M12, TOPCon, HJT

- Automation Level: Fully Automatic

- Delivery Time: 6–9 Months

What’s Included: Bill of Equipment

A turnkey production line is more than a collection of machines; it’s a fully integrated system where each component is selected to ensure seamless operation and high output. A 400 MW line includes a comprehensive set of state-of-the-art equipment designed for end-to-end automation.

Key equipment includes:

- Multiple high-speed stringers with a combined throughput of 14,400 cells per hour

- Fully automated layup and bussing systems to prepare cell matrices with precision

- Eight high-capacity laminators, processing 16 modules per cycle

- An automatic framing station for robust and precise module assembly

- An automatic junction box installation and potting system

- Inline Electroluminescence (EL) and Hi-Pot testers for quality assurance at critical stages

- Comprehensive Manufacturing Execution System (MES) integration for plant-wide monitoring and control

- A Class A+A+A+ Sun Simulator (Flasher) for final performance validation

Line Layout and Operations

The efficiency of a 400 MW plant stems from its intelligent layout and high degree of automation. The entire process, from cell loading to final module testing and sorting, is designed for continuous flow with minimal manual intervention. This approach not only maximizes throughput but also ensures exceptional consistency and quality.

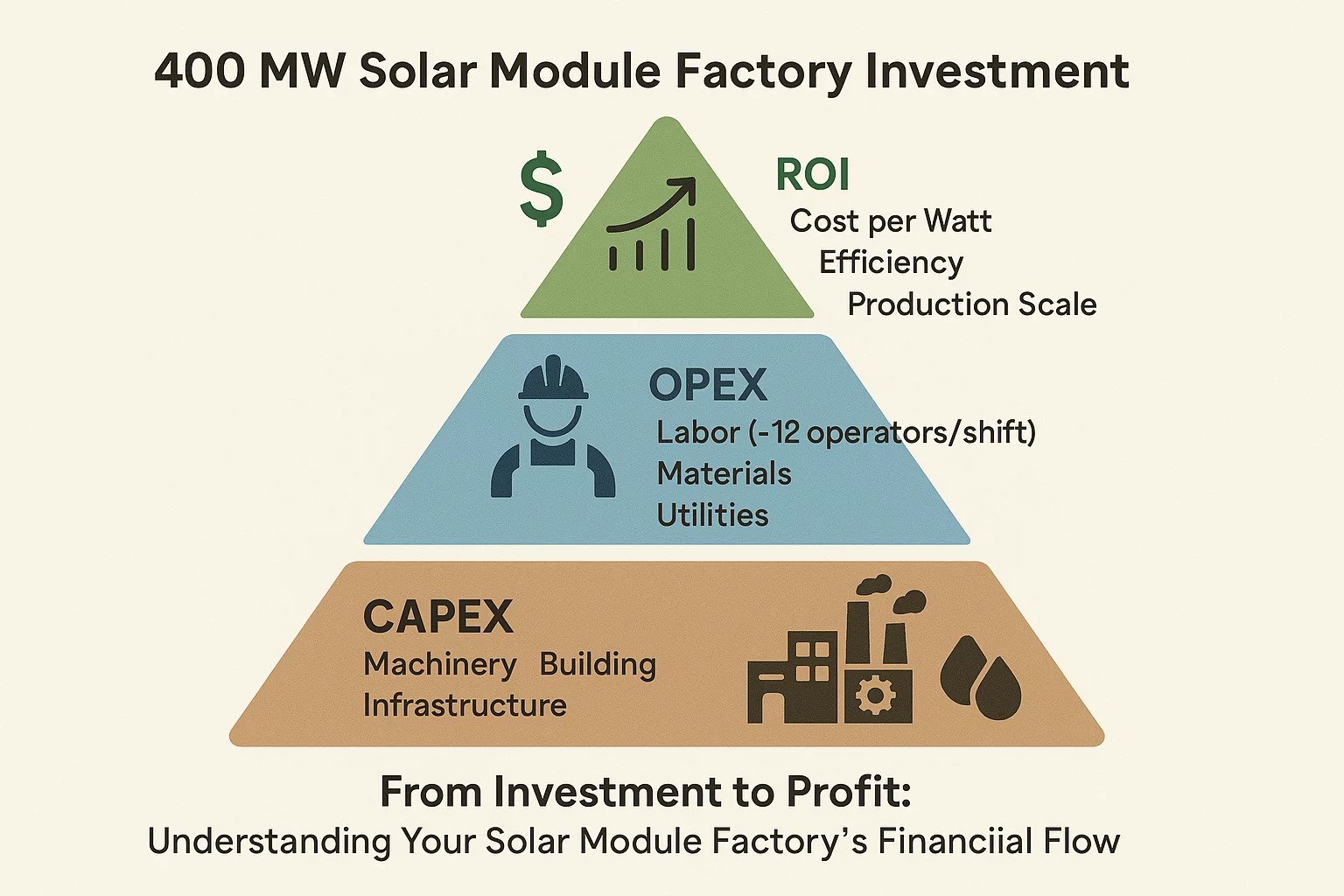

Thanks to its fully automated design, a typical shift requires only around 12 operators to oversee the line, manage material flow, and perform quality checks.

Advanced MES integration serves as the central nervous system of the plant. It provides real-time data from every machine, tracks each module with a unique ID, and logs quality control data from integrated checkpoints like the EL and Hi-Pot testers. This gives you complete operational visibility and full traceability for every module produced.

Investment, OPEX, and ROI

Investing in a 400 MW production line involves significant capital expenditure (CAPEX), but the line is engineered to deliver a highly competitive cost per watt. The scale of production and high level of automation reduce operational expenditures (OPEX), particularly labor costs, contributing to a strong return on investment (ROI).

It’s important to distinguish between typical and maximum output. The approx. 320 MW figure reflects a realistic annual production capacity under standard working conditions, while the 400 MW rating represents the line’s maximum potential. This financial model is designed for large-scale investors targeting utility-scale projects and export markets where efficiency and economies of scale are critical success factors.

A detailed business plan is essential to understand the specific financial outlook for your project. We can provide the necessary technical data to support your analysis.

Request Your Tailored Offer

Use Cases and Ideal Buyers

A production line of this scale is a strategic asset for specific market players:

- Industrial Manufacturers: Established or new manufacturers who aim to serve as a primary supplier for regional and international markets.

- EPCs and IPPs: Engineering, Procurement, and Construction companies or Independent Power Producers looking to vertically integrate their supply chain for utility-scale solar projects.

- Governments and Investors: Public or private entities focused on building national energy independence and creating a cornerstone industrial asset with a low cost-per-watt output.

Why J.v.G. Is Your Partner for Industrial-Scale Production

Choosing the right equipment supplier is only part of the equation. For a project of this magnitude, you need a partner with the experience, integrity, and long-term commitment to ensure your success.

As a founder-led, family-run company, we ground every project in over 25+ years of integrity and hands-on expertise. You aren’t just buying machines; you are gaining a dedicated team that stays with you from the initial concept to full operation and beyond. You are guided directly by our founders, who bring decades of real-world experience to your project.

Every line we design is a tailored technology platform configured for your specific site, market, and business goals. Our equipment is engineered to perform reliably even in the most demanding environments, thanks to our specialized DESERT & TROPIC Technology.

Our proven 6-Phase Process provides a clear and predictable roadmap, transforming your vision into a fully operational factory with confidence and clarity.

Speak Directly with Our Founders

Upgrade Path: Scaling from 400 MW to 800 MW

A 400 MW line is not an end point; it’s a powerful foundation. The modular design allows for future expansion. The most common upgrade path is to scale to an 800 MW capacity by mirroring the initial setup. This typically involves adding a parallel line, doubling the number of laminators, and integrating advanced logistics and automation to manage the increased material flow and output.

This foresight ensures your initial investment is secure and can grow with your market success.

400 MW vs. 800 MW Upgrade

| Feature | 400 MW Line | 800 MW Upgrade |

|---|---|---|

| Laminators | 8 | 16 |

| Automation | Fully Automatic | Advanced Integrated Logistics |

| Footprint | Standard | Expanded |

| Focus | High-volume production | Industrial dominance |

Explore a 300 MW Solar Module Production Line for medium-scale projects.

See the next level with an 800 MW Solar Module Production Line.

Frequently Asked Questions

What is the required factory footprint for a 400 MW line?

A 400 MW line typically requires a building footprint of approximately 12,000 square meters or more. A clear ceiling height of at least 8 meters is recommended to accommodate the equipment and ensure proper workflow.

How many staff members are needed per shift?

With its high level of automation, the line can be operated with only about 12 people per shift. This includes operators, material handlers, and quality control personnel.

What are the main utility requirements?

The primary utility demands are electrical power, compressed dry air (CDA), and cooling water. The peak electrical load can be several megawatts, so a stable and robust grid connection is essential. We provide a detailed utility plan specific to your final equipment configuration.

What is included for warranty, training, and spare parts?

Our turnkey solutions include a comprehensive warranty, on-site installation, and commissioning. We provide extensive training for your operational and maintenance teams. A recommended spare parts package is also included to ensure high uptime from day one.

What does the delivery and acceptance process look like?

The process follows clear milestones. After the down payment, manufacturing begins. Equipment is tested in our facilities before shipment. Final acceptance testing (FAT) is performed at your site after installation and commissioning to verify that the line meets all contractual performance specifications.

How does the upgrade to 800 MW work in practice?

Upgrading involves adding a second, parallel 400 MW line. We work with you to plan the factory layout from the start to accommodate this future expansion, ensuring a smooth and efficient integration process when you are ready to scale.

We invite you to discuss your project in detail. Let us help you translate your vision into a world-class manufacturing facility.