For entrepreneurs and energy companies looking to establish a significant regional presence, the leap from entry-level to mid-scale manufacturing is a critical move. A 25 MW line offers a solid starting point, but the demand for greater output often arises sooner than expected. The 50 MW semi-automatic production line is designed for this exact phase of growth, striking a powerful balance between increased throughput, manageable investment, and strategic scalability.

This guide provides a clear overview of a typical 50 MW solar module factory, detailing its equipment, operational requirements, and investment logic. All data is based on our official offers and reflects real-world project specifications.

Executive Overview: The Strategic Mid-Scale Solution

A 50 MW production line is an ideal solution for regional manufacturers and EPCs aiming to capture a larger share of their market. It effectively doubles the output of a 25 MW line, primarily by integrating a larger laminator capable of processing two modules per cycle. Crucially, this is achieved with only a marginal increase in the factory footprint, making it a highly efficient upgrade.

Key advantages of this configuration include:

- High Throughput: A high-speed stringer operates at 1,800 cells per hour (cph), feeding a streamlined production process.

- Enhanced Efficiency: The laminator processes two modules simultaneously, significantly boosting output without doubling the equipment footprint.

- Balanced Automation: The semi-automatic layup process ensures high precision and consistency while keeping initial capital expenditure (CAPEX) and operator training requirements manageable.

- Future-Proof Scalability: The line is designed as a modular base that can be expanded and further automated to reach a 100 MW capacity in the future.

Technical Specifications

The specifications below define a robust and versatile production line capable of manufacturing modern, high-efficiency solar panels.

- Cell Throughput: 1,800 cells per hour

- Lamination Capacity: 2 modules per cycle

- Typical Annual Capacity: ~40 MW per year (2 shifts, 280 days)

- Maximum Annual Capacity: 50 MW per year (3 shifts, 330 days)

- Maximum Panel Size: 2,400 mm × 1,400 mm

- Supported Cell Types: M2 to M12

- Supported Busbars: Up to 20 BB

- Automation Level: Semi-automatic layup

- Typical Delivery Time: 6–9 months from down payment

- Standard Payment Terms: 30% down, 60% before shipment, 5% post-installation, 5% final acceptance

What’s Included: Core Production Equipment

A complete 50 MW line includes all the stations needed to transform raw solar cells into finished, certified modules. The comprehensive equipment list features key machinery, including:

- High-Speed Stringer: The heart of the line, automatically soldering cells into strings at a rate of 1,800 cph.

- Semi-Automated Layup Station: Assists operators in precisely positioning the glass, EVA, cell matrix, and backsheet.

- Bussing Station: Where strings are interconnected—either manually or with assistance—into a complete module matrix.

- High-Volume Laminator: A large-format laminator designed to cure two modules in a single cycle.

- Automatic Foil Cutter & Placing Station: Precisely cuts and positions backsheet and EVA foils.

- Trimming Station: For cleaning excess material from the module edges after lamination.

- Semi-Automatic Framing Station: Applies and secures the aluminum frames to the laminate.

- J-Box Station: Where junction boxes are attached and sealed. This can be upgraded to a semi-automatic process.

- A+A+A+ LED Flasher: Simulates sunlight to test the final electrical performance (I-V curve) of each module.

- Hi-Pot & EL Testers: Essential quality control stations to test for insulation integrity (Hi-Pot) and micro-cracks in cells (Electroluminescence).

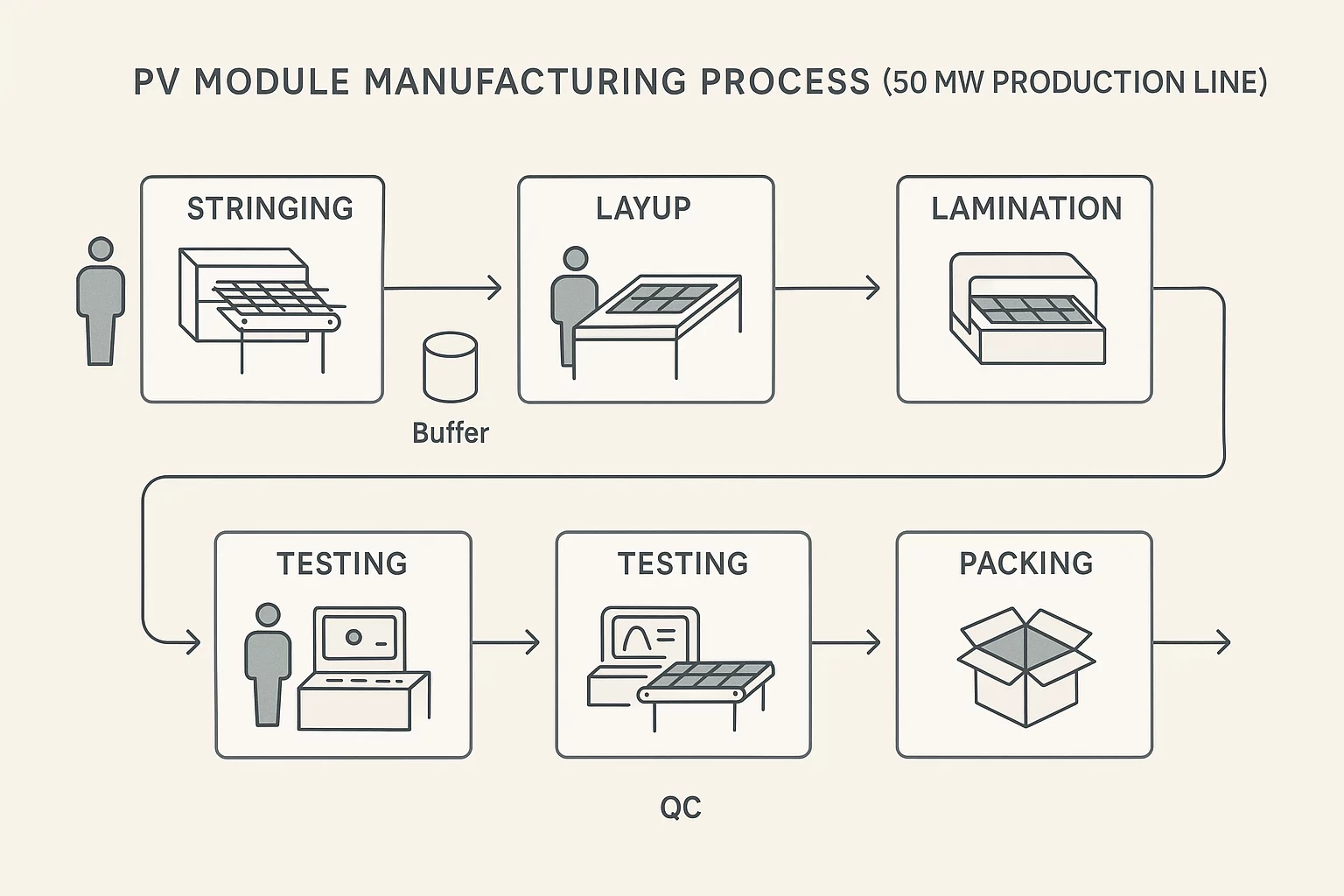

Line Layout and Operations

The production process follows a linear, logical flow designed for efficiency and quality control. The main stages are:

- Stringing: Solar cells are soldered into strings.

- Layup: The module “sandwich” (glass, EVA, cell matrix, EVA, backsheet) is assembled.

- Lamination: The sandwich is heated and pressed to create a durable, weatherproof laminate.

- Framing & Finishing: The frame and junction box are attached.

- Testing: Each module undergoes comprehensive EL, Hi-Pot, and performance testing.

- Packing: Finished modules are sorted, palletized, and prepared for shipment.

A 50 MW line typically requires approximately 20 operators per shift. While this is a slight increase compared to a 25 MW line, it yields a disproportionately larger output, boosting overall labor efficiency. The layout includes dedicated buffer zones, material handling trolleys, and integrated QC checkpoints to ensure a smooth and reliable workflow.

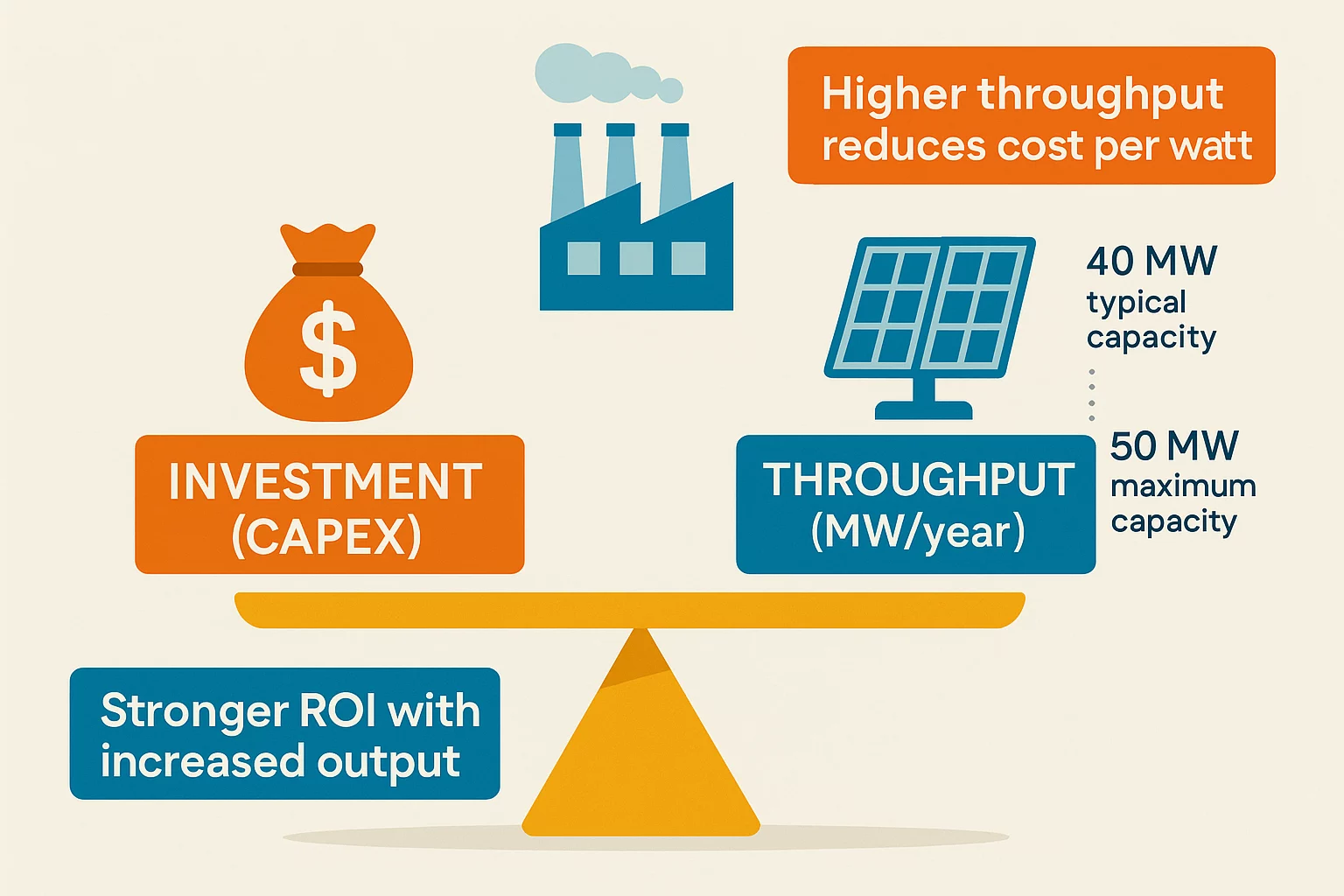

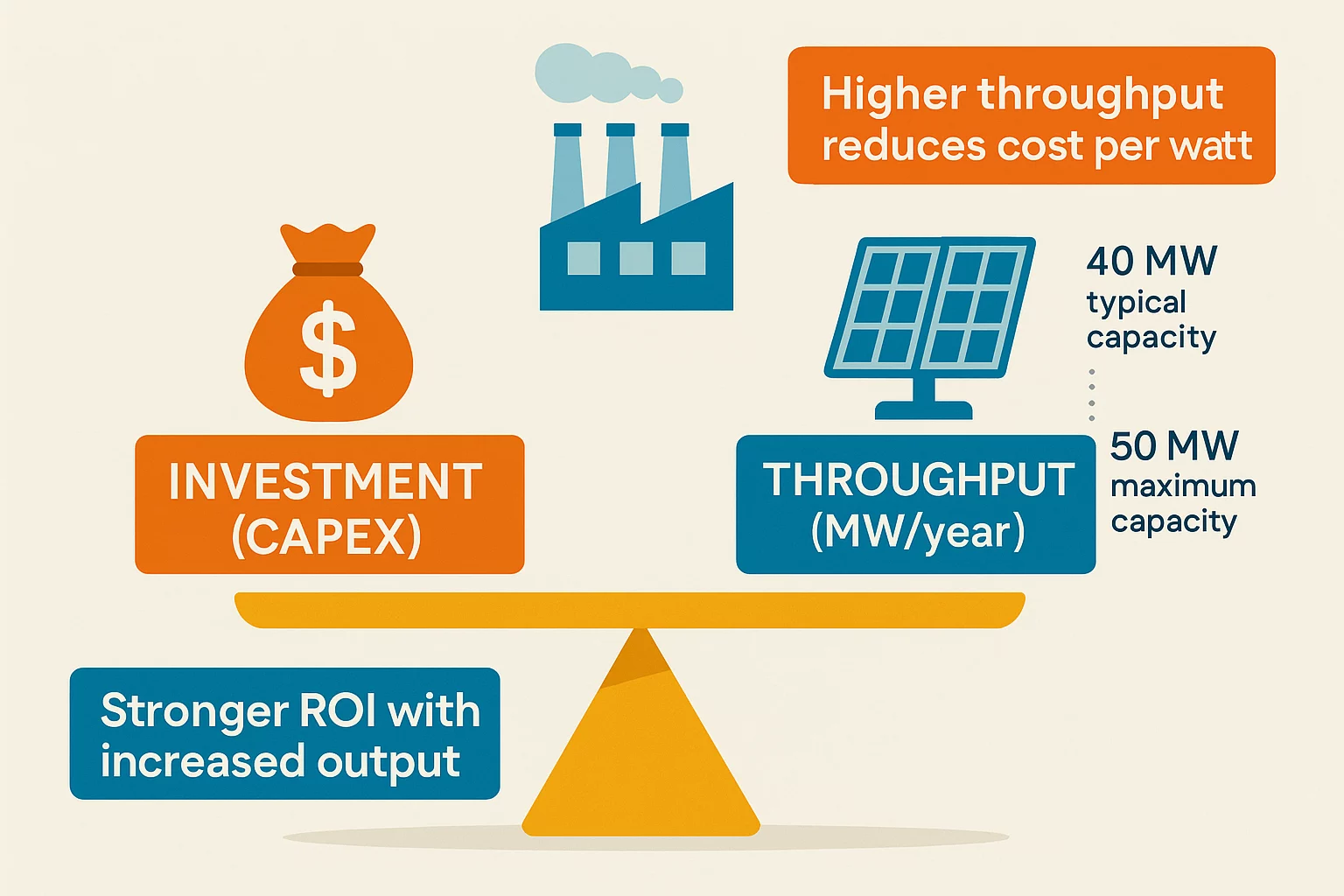

Investment, Operating Costs (OPEX), and ROI

While the CAPEX for a 50 MW line is moderately higher than for an entry-level setup, the return on investment (ROI) is significantly stronger. The higher throughput directly reduces the manufacturing cost per watt, improving margins and accelerating profitability.

It’s important to distinguish between typical and maximum output. Most factories operate on a two-shift, 280-day schedule, which yields a realistic annual capacity of ~40 MW. The maximum nameplate capacity of 50 MW is achievable with a three-shift, 330-day operation. Planning your business model around the typical capacity ensures a more conservative and reliable forecast.

For a detailed financial projection tailored to your specific project, region, and business goals, we recommend a direct consultation.

Request a Tailored Offer

Use Cases and Ideal Buyers

The 50 MW production line is designed for specific business profiles that have outgrown the startup phase:

- Growing Regional Manufacturers: Companies looking to double their capacity to meet rising local demand.

- EPCs and Project Developers: Businesses seeking to vertically integrate and secure their module supply chain for mid-sized utility or commercial projects.

- Local-Content Initiatives: Government-supported projects that require a substantial and reliable local manufacturing presence.

- Strategic Investors: Entrepreneurs who understand the value of scaling and prioritize a stronger ROI by balancing initial CAPEX with higher production volume.

Why Choose J.v.G. as Your Partner

You are not just buying machinery; you are choosing a partner to guide you from concept to full-scale operation. J.v.G. is a founder-led, family-run engineering company with over 25 years of hands-on experience building solar factories worldwide.

- Experience and Integrity: Our business is built on a foundation of German engineering integrity. We provide honest advice and reliable solutions—a commitment upheld by our founders in every project.

- Technology Tailored to You: We do not offer one-size-fits-all solutions. Our production lines are modular and scalable, allowing us to deliver tailored technology that meets your exact needs and budget.

- Engineered for Your Climate: For projects in extreme environments, our specialized DESERT & TROPIC Technology ensures your modules deliver long-term performance and reliability, even in high heat and humidity.

- A Proven Roadmap to Success: We guide you through our proven 6-Phase Process, providing a clear roadmap that minimizes risk, ensures transparency, and covers every step from initial planning to factory acceptance.

Talk to our founders

Your Path to Future Growth: The Upgrade to 100 MW

A 50 MW line is not an endpoint, but a strategic platform for future expansion. The layout is designed to accommodate a seamless upgrade to a 100 MW capacity. This is typically achieved by adding a second high-volume laminator and introducing higher levels of automation in the layup, bussing, and framing stations. This phased approach allows you to scale your investment in line with your market growth.

| 50 MW Line | 100 MW Upgrade Path |

|---|---|

| Laminators: 1 (processing 2 modules/cycle) | Laminators: 2+ (parallel processing) |

| Layup: Semi-automatic | Layup: Fully automatic |

| Footprint: Standard | Footprint: Expanded to accommodate new machinery |

| Investment: Moderate CAPEX | Investment: Phased, incremental CAPEX |

Explore Other Production Capacities:

- Entry-Level: 25 MW Solar Module Production Line

- Full-Scale: 100 MW Solar Module Production Line

Frequently Asked Questions

What is the required factory footprint and ceiling height for a 50 MW line?

A typical 50 MW line requires a floor space of approximately 2,000–2,500 square meters. A minimum ceiling height of 6 meters is recommended to accommodate equipment and material handling.

How many staff are needed to run one shift?

One shift typically requires around 20 operators, including production staff, quality control personnel, and a shift supervisor.

What are the primary utility requirements?

The main requirements are a stable electrical power supply (approx. 350-450 kW), compressed air, and an internet connection for remote support. A detailed utility plan is provided during the project planning phase.

What warranty and training are included?

We provide a comprehensive warranty on all equipment. On-site installation, commissioning, and extensive training for your operators and maintenance staff are a standard part of our turnkey solution.

What is the complete timeline from order to production?

From the initial down payment, the typical timeline is 6–9 months for equipment delivery. Installation and commissioning on-site usually take an additional 6–8 weeks.

How complex is it to upgrade from 50 MW to 100 MW?

The upgrade is straightforward by design. The modular layout allows for the addition of a second laminator and other automated stations with minimal disruption to your existing operations.

Planning a solar manufacturing facility is a significant undertaking. Our role is to provide the technical expertise and partnership to ensure your project is a long-term success.

Request a Tailored Offer

Download Sample Offer (PDF)