Executive Overview

The 200 MW production line marks a significant step into high-volume, fully automated solar module manufacturing. This line is engineered for established manufacturers, large-scale energy project developers (EPCs), and regional market leaders seeking substantial output, maximum efficiency, and a competitive cost structure.

With a combined stringer capacity of 7,200 cells per hour and four high-capacity laminators processing eight modules per cycle, this line is built for industrial-scale production. It minimizes manual intervention, ensures consistent quality, and delivers a highly competitive cost per watt.

All specifications are based on official J.v.G. technology GmbH project offers, reflecting proven, real-world engineering and performance data.

Technical Specifications

This production line balances high throughput with advanced technology, supporting the latest cell formats and ensuring future-proof operations.

| Parameter | Specification |

|---|---|

| Cell Throughput | 7,200 cells per hour |

| Modules per Cycle | 8 (in four laminators) |

| Typical Capacity | approximately 160 MW per year (actual) |

| Maximum Capacity | 200 MW per year (nominal) |

| Max Panel Size | 2,400 × 1,400 mm |

| Supported Cell Types | M2–M12, TOPCon, HJT |

| Busbars | Up to 20 BB |

| Automation Level | Fully automatic layup & bussing |

| Delivery Time | 6–9 months from order confirmation |

| Standard Payment Terms | 30% down payment, 60% before shipment, 5% on installation, 5% on final acceptance |

What’s Included: Core Equipment

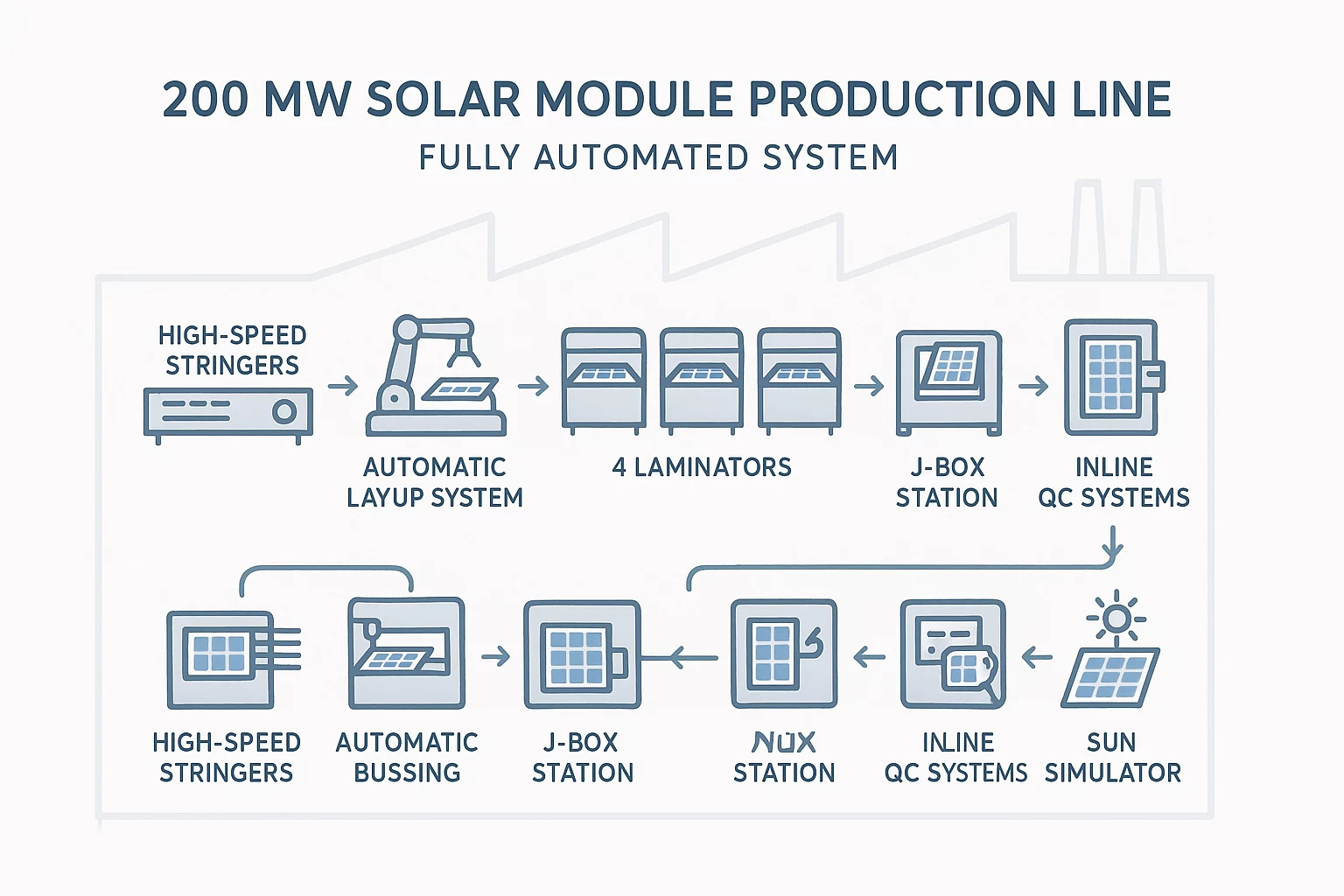

A 200 MW turnkey line from J.v.G. is a complete system, with every machine selected and integrated for seamless operation. The core bill of equipment includes:

- High-Speed Stringers: High-speed stringers with a combined, balanced output of 7,200 cells per hour.

- Fully Automatic Layup System: Robotic handling places cell strings precisely onto glass and backsheet, eliminating manual error.

- Automatic Bussing Station: Connects cell strings automatically, ensuring consistent, high-quality electrical connections.

- Lamination Line: Four parallel laminators, each with a capacity of two large-format modules, for a total of eight modules per lamination cycle.

- Automatic Framing Station: Applies and secures aluminum frames with high precision.

- Automatic Junction Box Station: Attaches and tests junction boxes without manual handling.

- Testing & Quality Control: Includes inline Electroluminescence (EL) and Hi-Pot testers to detect micro-cracks and ensure insulation integrity.

- Sun Simulator (Flasher): A Class A+A+A+ flasher to test and classify finished modules according to their power output.

- Optional MES Integration: Can be fully integrated with a Manufacturing Execution System (MES) for smart factory monitoring and data management.

Line Layout & Operations

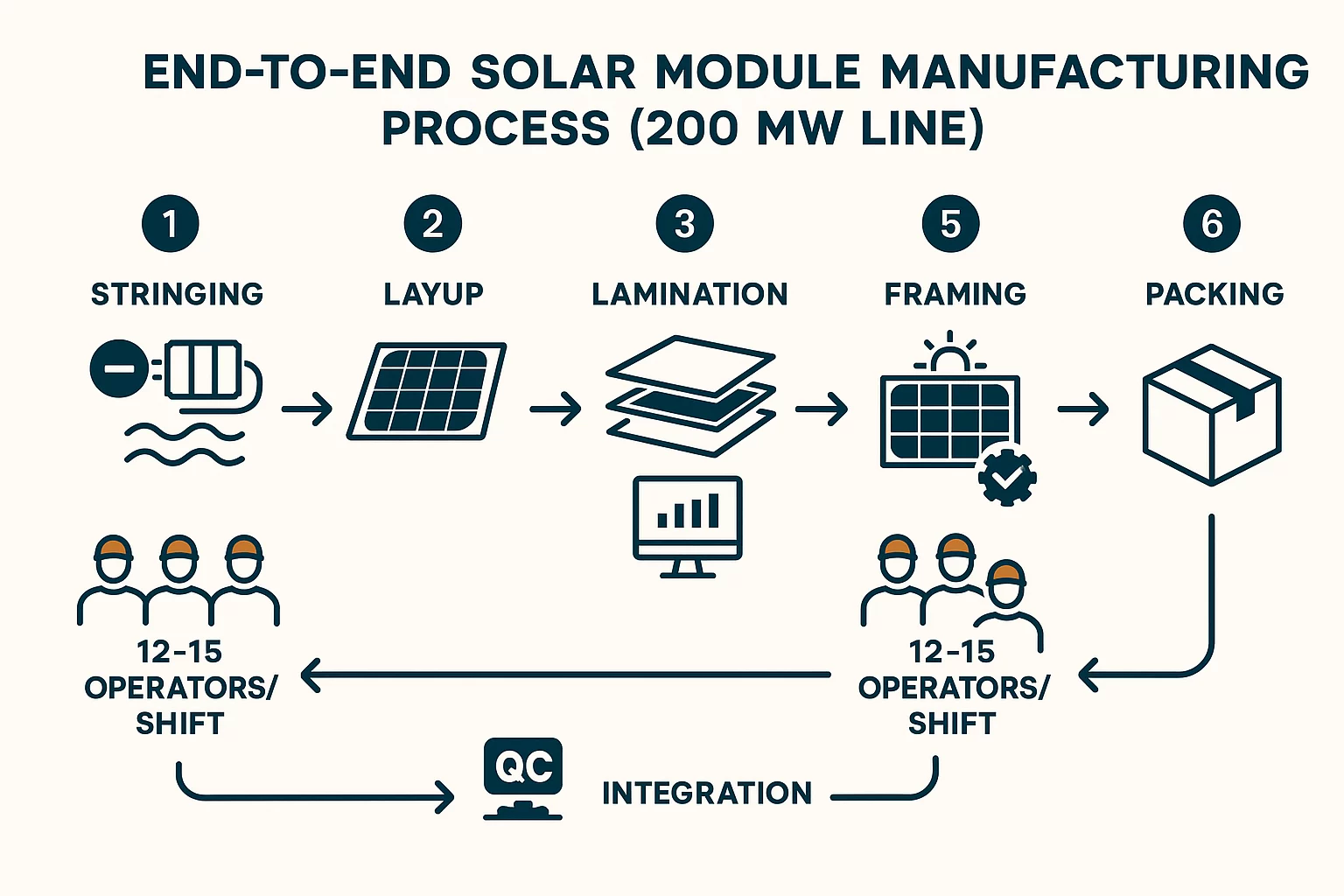

The 200 MW line is designed for end-to-end automation, creating a continuous flow from raw materials to finished products. The process flows from stringing, layup, and bussing to lamination, framing, and final testing before packing.

This high level of automation significantly reduces the need for manual labor, with a typical shift requiring only 12–15 operators for material loading, quality supervision, and system monitoring. Integrated digital controls and inline QC systems provide real-time feedback, allowing operators to maintain peak performance and address any issues immediately.

Investment, Operating Costs & ROI

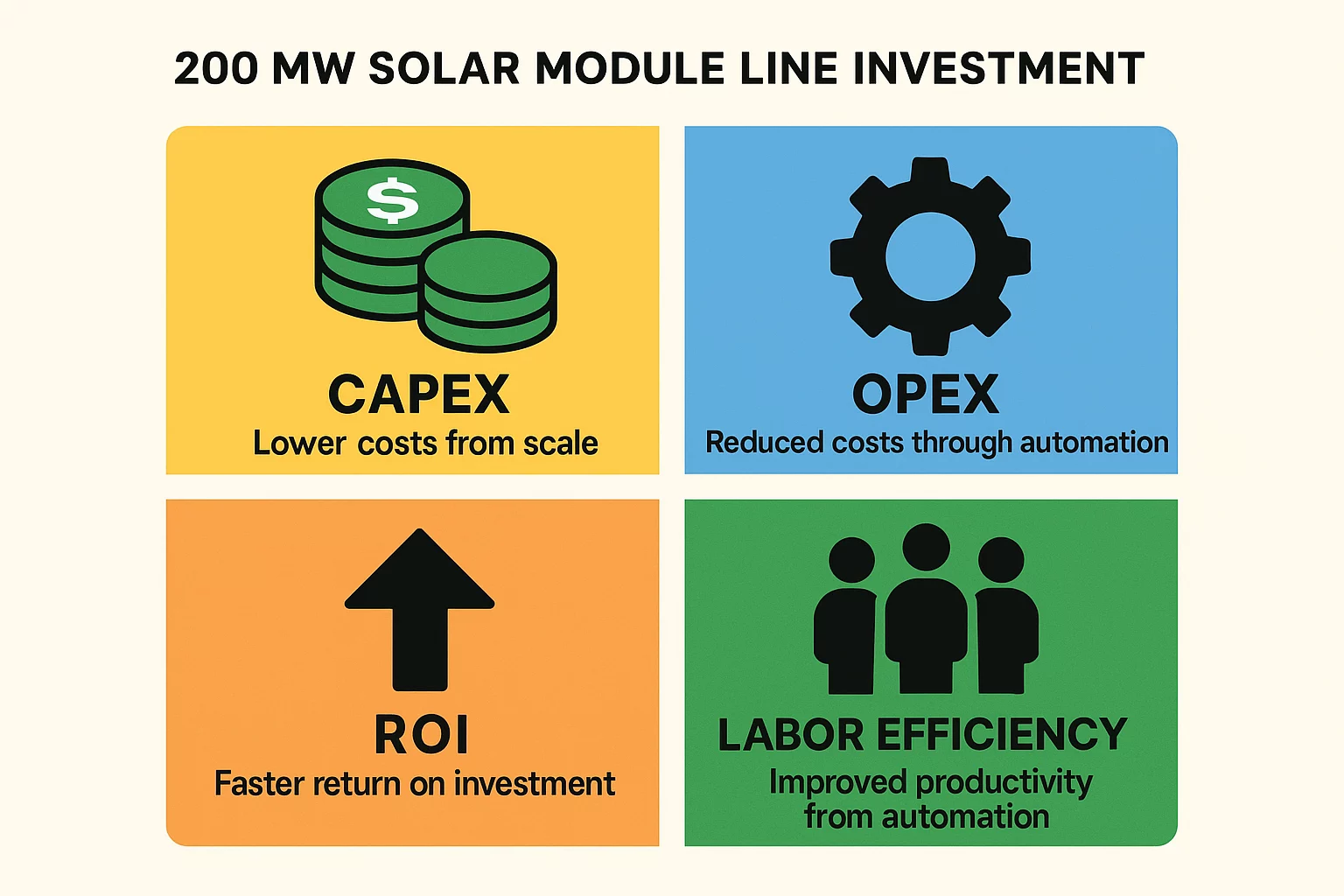

While the capital expenditure (CAPEX) for a 200 MW line is higher than for a smaller 150 MW setup, the investment delivers significant operational advantages. The primary benefit is a dramatic increase in labor efficiency, which substantially lowers the manufacturing cost per watt.

While the line is rated for a nominal 200 MW per year, a realistic production target—accounting for maintenance and material flow—is approximately 160 MW. This achievable output provides a reliable foundation for your business plan.

The return on investment is driven by a highly competitive cost structure, enabling you to supply large-scale utility and commercial projects with confidence. This scale also makes your operation future-proof, positioning you as a dominant player in your market.

Use Cases & Ideal Buyers

This production capacity is tailored for specific business models and market positions:

- Large Regional Manufacturers: Companies seeking to expand existing capacity to meet growing demand and defend market share.

- EPCs and IPPs: Vertically integrating project developers who want to control their module supply chain, reduce costs, and ensure quality for utility-scale and large commercial solar farms.

- Strategic Investors: Business leaders entering the PV manufacturing space who require high throughput and reliable automation to compete effectively from day one.

Why J.v.G. Is Your Partner for Growth

Choosing a technology supplier is about more than equipment; it’s about securing a partner for the life of your factory. At J.v.G., our entire business is built on trust and long-term success.

Our approach is founded on over 25 years of integrity and a founder-led philosophy that gives you direct access to the decision-makers. You can meet the founders who personally oversee every project. We provide tailored technology solutions that are modular, scalable, and designed for your specific site conditions. This includes our specialized DESERT® & TROPIC® Technology, engineered to ensure module durability in the world’s harshest climates.

We deliver on this commitment through our proven 6-Phase Process, which provides a complete roadmap from your initial vision to a fully operational and profitable factory.

Upgrade Path: Scaling to 300 MW and Beyond

The 200 MW line is designed with growth in mind. Its modular layout allows for straightforward expansion. By adding more stringers, a fifth laminator, and advanced automation components, your factory can be scaled to 300 MW or more, protecting your initial investment and allowing you to grow with the market.

For more details on other capacity levels, see our guides on the 150 MW Solar Module Production Line and the 300 MW Solar Module Production Line.

| Feature | 200 MW Line | Upgrade to 300 MW |

|---|---|---|

| Laminators | 4 units | Add 1–2 additional units |

| Stringers | Matched to 200 MW | Add stringers to balance new capacity |

| Automation | Fully automated | Enhance with advanced robotics/conveyors |

| Investment | Initial CAPEX | Incremental, modular investment |

Frequently Asked Questions

What is the required factory footprint for a 200 MW line?

You should plan for a facility of approximately 7,000–8,000 square meters (75,000–86,000 sq ft). A minimum ceiling height of 6–8 meters is required to accommodate the machinery and ensure proper workflow.

How many people are needed to run the factory?

Thanks to the high level of automation, a typical shift requires only 12–15 operators. This team is responsible for supplying materials to the line, overseeing automated processes, and performing final quality checks.

What are the main utility requirements?

A stable industrial electricity supply is critical. The line also requires a significant supply of compressed air for pneumatic systems and process water for cooling the laminators and other equipment. We provide detailed utility specifications during the project planning phase.

What is included for warranty, training, and spare parts?

Our turnkey solution includes a comprehensive warranty on all equipment. We provide extensive onsite training for your operators and maintenance staff during commissioning. A starter package of critical spare parts is also included, and we offer ongoing support to ensure you have the components you need.

How does the delivery and acceptance process work?

The process follows our 6-Phase model. After manufacturing (6–9 months), the equipment is shipped to your site. Our engineers then handle the installation and commissioning. The process concludes with a formal Final Acceptance Test (FAT) to demonstrate the line’s guaranteed performance and output.

How complex is the upgrade from 200 MW to 300 MW?

The upgrade path is straightforward due to the modular design. The primary additions are more stringers and one or two laminators to address production bottlenecks. The factory layout is planned from the outset to accommodate this future expansion with minimal disruption.

We understand that an investment of this scale requires careful consideration. Our team is here to provide the clarity and guidance you need.

Downloads and Contact

Download Sample Offer (PDF) → /downloads/200mw-offer.pdf

Request a Tailored Offer → /contact