A Strategic Roadmap: From Manual Production to a Fully Automated Solar Factory

The vision for a new solar module factory is often one of full automation: robotic arms moving with precision, production flowing seamlessly, and output reaching maximum capacity. While this is an excellent long-term goal, the journey doesn’t have to be a single, massive leap.

For many entrepreneurs and investors, the most intelligent path forward is a phased approach—a strategy that balances ambition with capital, manages risk, and builds a foundation for sustainable growth. This method allows you to enter the market faster, learn the business from the ground up, and scale your operations in lockstep with market demand. It transforms a monumental investment into a series of manageable, strategic upgrades. This isn’t about starting small; it’s about starting smart.

Understanding the Levels of Automation

Before mapping out the journey, it’s essential to understand the destinations. In solar module manufacturing, production lines generally fall into three categories.

Phase 1: The Manual Foundation

A manual line relies heavily on skilled operators for most processes, from cell stringing to framing. This is a common and effective entry point into the market.

Advantages: The primary benefit is a significantly lower initial investment. A manual line also offers flexibility and can be commissioned relatively quickly, allowing you to begin production and generate revenue sooner.

Challenges: Throughput is limited by the speed and number of operators. Consistency also depends on rigorous training and quality control, as human error can impact module performance and longevity.

Phase 2: Strategic Semi-Automation

This is arguably the most critical growth stage. A semi-automated line introduces machinery for specific, high-impact processes while retaining manual labor for others. As industry research from the Fraunhofer Institute for Solar Energy Systems shows, targeted automation in key areas is a primary driver for reducing manufacturing defects and improving module efficiency.

Advantages: This approach results in a substantial increase in throughput, quality, and consistency where it matters most. It boosts your production capacity and the bankability of your product without the cost of a fully automated line.

Challenges: The main challenge lies in choosing the right processes to automate first and ensuring the new equipment can integrate with your future plans.

Phase 3: Fully Automated Production

This is the end goal for many large-scale producers. A fully automated line uses robotics and integrated conveyor systems for nearly every step, from loading raw materials to testing and sorting finished modules.

Advantages: This level offers the highest throughput, lowest operational cost per unit, and unparalleled consistency. Data from the International Technology Roadmap for Photovoltaic (ITRPV) confirms that high automation is key to achieving the cost reductions seen in the industry over the past decade.

Challenges: The initial capital expenditure is very high, and the system is less flexible to changes in module design or technology. Profitability depends on stable, high-volume demand.

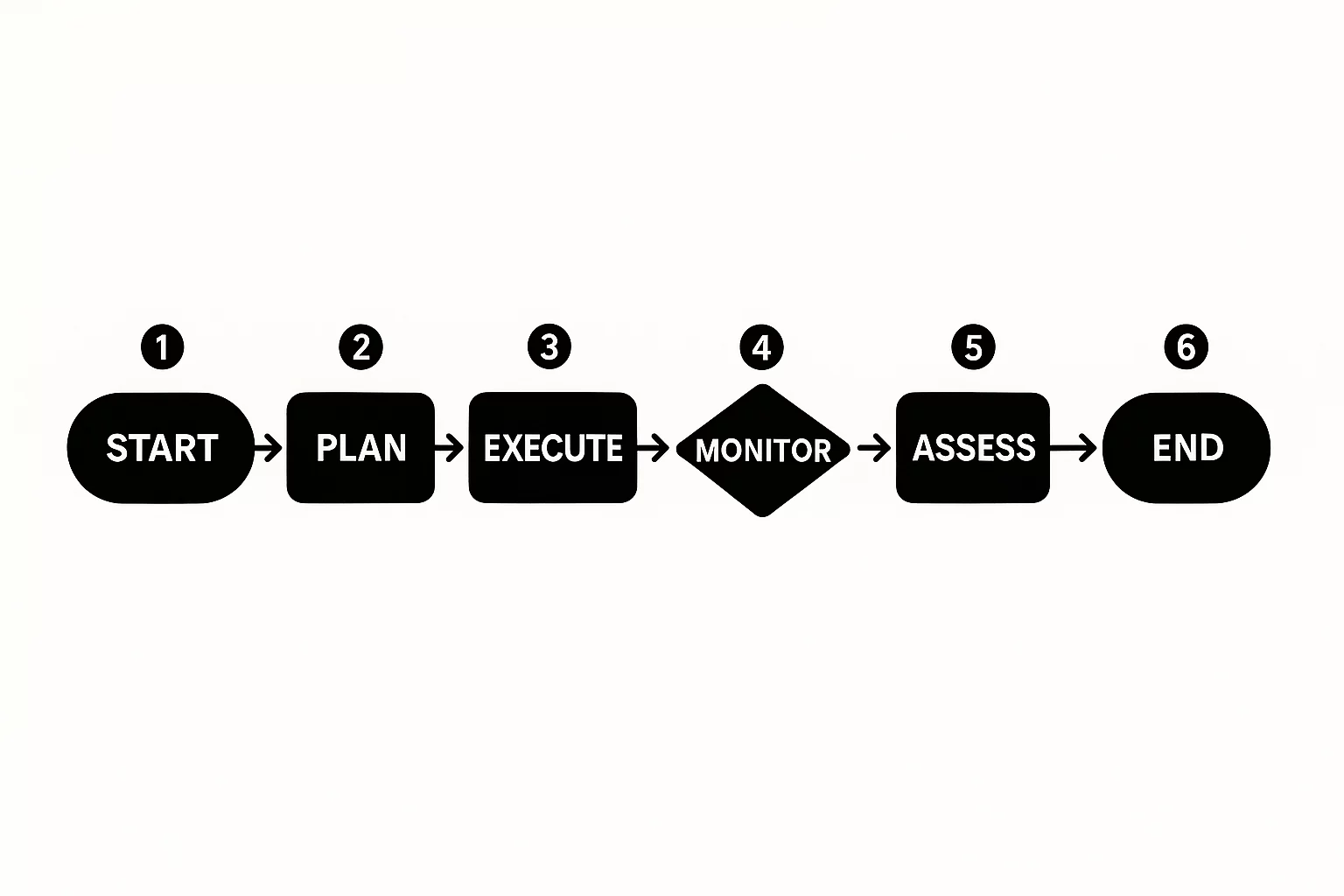

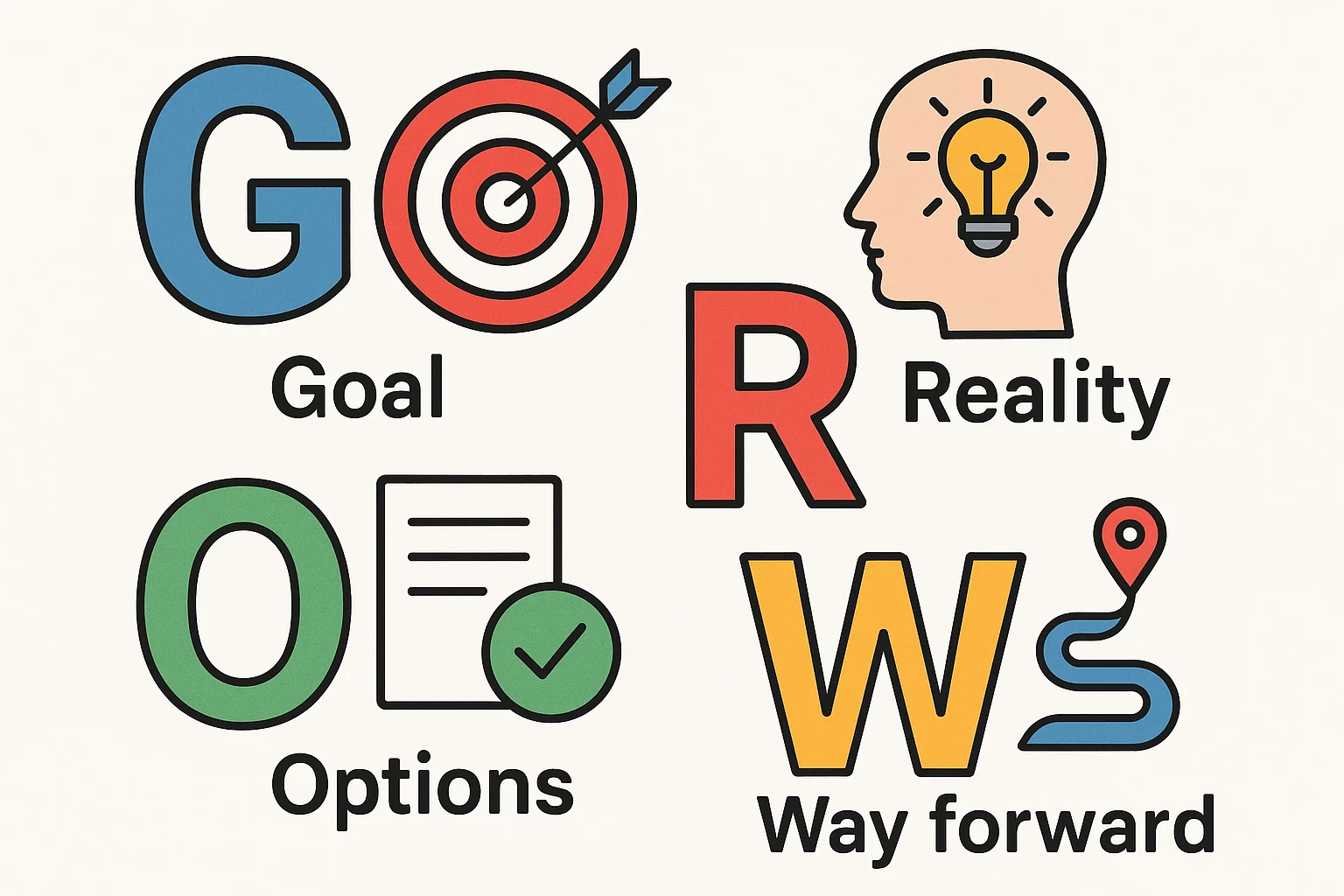

Your Roadmap for Scaling: Which Processes to Automate First

The transition from a manual to a semi-automated line isn’t just about buying a machine; it’s a strategic decision. The goal is to automate the biggest bottlenecks and the most critical quality checkpoints first.

First Upgrade: The Stringer

Soldering solar cells together into ‘strings’ is a repetitive, delicate process with an enormous impact on the final module’s power output. Manual operation can introduce micro-cracks or inconsistent soldering, which can degrade performance over time.

Automating this step with a semi-automated stringer delivers an immediate and significant return. Modern stringers can handle advanced cell technologies like PERC and TOPCon with a precision that is impossible to replicate by hand, ensuring each module performs at its peak potential.

Second Upgrade: The Laminator

The laminator is the heart of the production line. It uses heat and pressure to encapsulate the solar cells between layers of glass and protective backsheets, sealing them from moisture and environmental stress for the next 25-30 years.

An automated laminator ensures every module experiences the exact same temperature, pressure, and time cycle. This level of consistency is fundamental to your product’s long-term reliability and durability. Upgrading from a manual or less precise system to a high-quality automated laminator is one of the most important investments you can make in your brand’s reputation.

The Key to Success: Planning for Future Integration

Investing in your first piece of automated equipment isn’t just about solving today’s bottleneck; it’s about planning for tomorrow’s integrated factory.

This is where the choice of partner becomes critical. The equipment you select for Phase 2 must be designed to communicate with other machines and fit seamlessly into a larger, fully automated system later. Choosing an isolated machine from one supplier and another from a different one often creates integration problems that are expensive and difficult to solve. A successful scaling strategy relies on a unified technology platform that ensures our turnkey production lines can be built out piece by piece.

Frequently Asked Questions (FAQ)

-

What is a realistic initial investment for a manual production line?

While the initial investment is significantly lower than for an automated line, the exact amount varies based on capacity and region. The key is to focus on high-quality manual tools and robust quality control systems. This approach lowers the financial barrier to entry while building a strong foundation of operational excellence. -

How long does an upgrade from manual to semi-automated typically take?

The physical installation can be relatively quick, but the process must include planning, line layout adjustments, and operator training. With an experienced partner, a well-planned upgrade can be executed in a matter of weeks with minimal disruption to your existing production. -

Is it possible to mix equipment from different suppliers?

While possible, it is not recommended. Integrating machines from various manufacturers can lead to software incompatibilities, communication errors between stations, and servicing difficulties. Working with a single partner who provides a holistic, integrated solution ensures every component works together perfectly. -

What kind of training is required for semi-automated equipment?

Operators need training not just on running the machine, but also on basic maintenance and troubleshooting. The best equipment partners provide comprehensive, on-site education. Look for partners who offer our hands-on support and training programs that empower your team to operate the line with confidence and autonomy.

Your Next Step

A phased automation strategy is a proven, intelligent way to build a successful solar module manufacturing business. This strategy allows you to grow your capacity as your market and expertise expand, ensuring every investment is made at the right time for the right reasons.

Ultimately, the most important decision you will make is choosing a partner who understands this journey and can guide you through every phase.

Ready to build your roadmap? Contact our team to discuss how a phased automation strategy can bring your solar factory vision to life.