Building a Solar Factory in the Middle East: A Guide to De-risking Your Investment

The opportunity is clear. With regional solar manufacturing capacity projected to reach 44 GW by 2029, the Middle East is poised to become a self-sufficient, and even exporting, powerhouse.

Governments are committed, capital is available, and the strategic push for localized supply chains is undeniable.

For investors, EPCs, and industrial leaders like you, however, the central question is not if the opportunity exists, but how to capture it without falling into the region’s unique operational traps. Manufacturing solutions designed for moderate climates simply fail in the face of a desert environment.

This is not a high-level market report. It is a practical guide for decision-makers on building a reliable, efficient, and profitable solar module factory in one of the world’s most demanding climates. It draws on our 25-plus years of hands-on engineering experience delivering successful turnkey projects where others have struggled.

J.v.G.’s experienced engineering team brings specialized know-how and founder-level engagement to solar manufacturing projects in harsh Middle Eastern climates.

Understanding the Landscape and Its Hidden Risks

Most industry analyses focus on the strategic drivers for solar manufacturing in the Middle East: economic diversification, energy independence, and ambitious decarbonization goals. While correct, they often overlook the critical technical challenges that determine a project’s long-term success or failure.

Reliance on imported raw materials and a developing skilled labor market are known business hurdles. But the most significant risk lies in underestimating the harsh environment itself. The desert does not forgive poor engineering. Basing an investment on standard European or Asian factory models is an unnecessary risk.

The Desert Challenge:

Overcoming a Hostile Environment

A successful solar factory in the Middle East must be engineered from the ground up to overcome three specific challenges that standard systems cannot handle. Failing to address any one of them can compromise your entire operation.

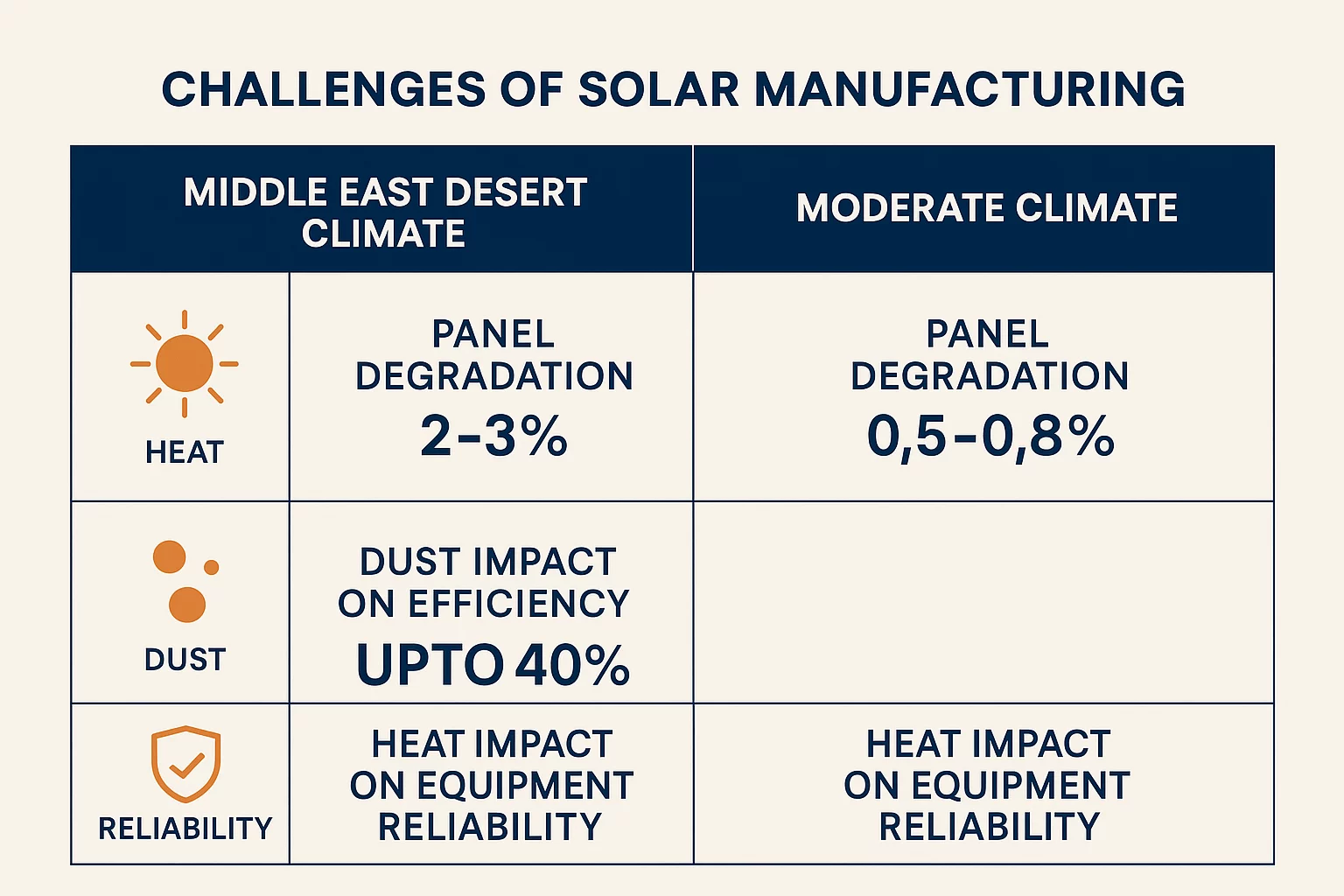

The Heat Factor

Extreme ambient temperatures place immense stress on manufacturing equipment. Inadequately cooled systems suffer from frequent breakdowns, reduced accuracy, and a shorter operational lifespan. The result is costly downtime and inconsistent production quality—precisely when you need to be ramping up.

The Dust Dilemma

Airborne sand and fine dust are more than a nuisance; they are a direct threat to production. Dust accumulation can reduce a finished panel’s efficiency by 15-40%. Worse, if contaminants penetrate the production line, especially during lamination, they can cause permanent defects, leading to higher rejection rates and damaging your brand’s reputation for quality.

The Reliability Gap

These environmental factors create a significant reliability gap. Solar panels produced in and for desert climates can have their performance degrade by 2–3% per year, far exceeding the 0.5–0.8% standard in moderate climates. This accelerated degradation severely impacts the bankability and long-term financial returns of your factory’s products and, by extension, the solar projects that use them. Standard factory designs simply lack the robustness to close this gap.

The J.v.G. Solution: Engineered for the Desert

For over two decades, we have seen these challenges defeat underprepared ventures. In response, we developed our proprietary DESERT Technology—a complete, integrated system designed specifically for building and operating solar module factories in hot, arid, and dusty environments.

This is not a set of minor modifications but a fundamental rethinking of the production line, focused on durability, stability, and long-term performance.

Our DESERT Technology addresses the core environmental risks through:

This approach ensures your factory operates at peak efficiency with minimal downtime, producing high-quality, durable modules that command trust in the market. You are not just buying machines; you are investing in an engineering philosophy proven to withstand the desert.

The J.v.G. Partnership Model: Your De-Risking Framework

Your Blueprint for Success: A De-Risked Approach

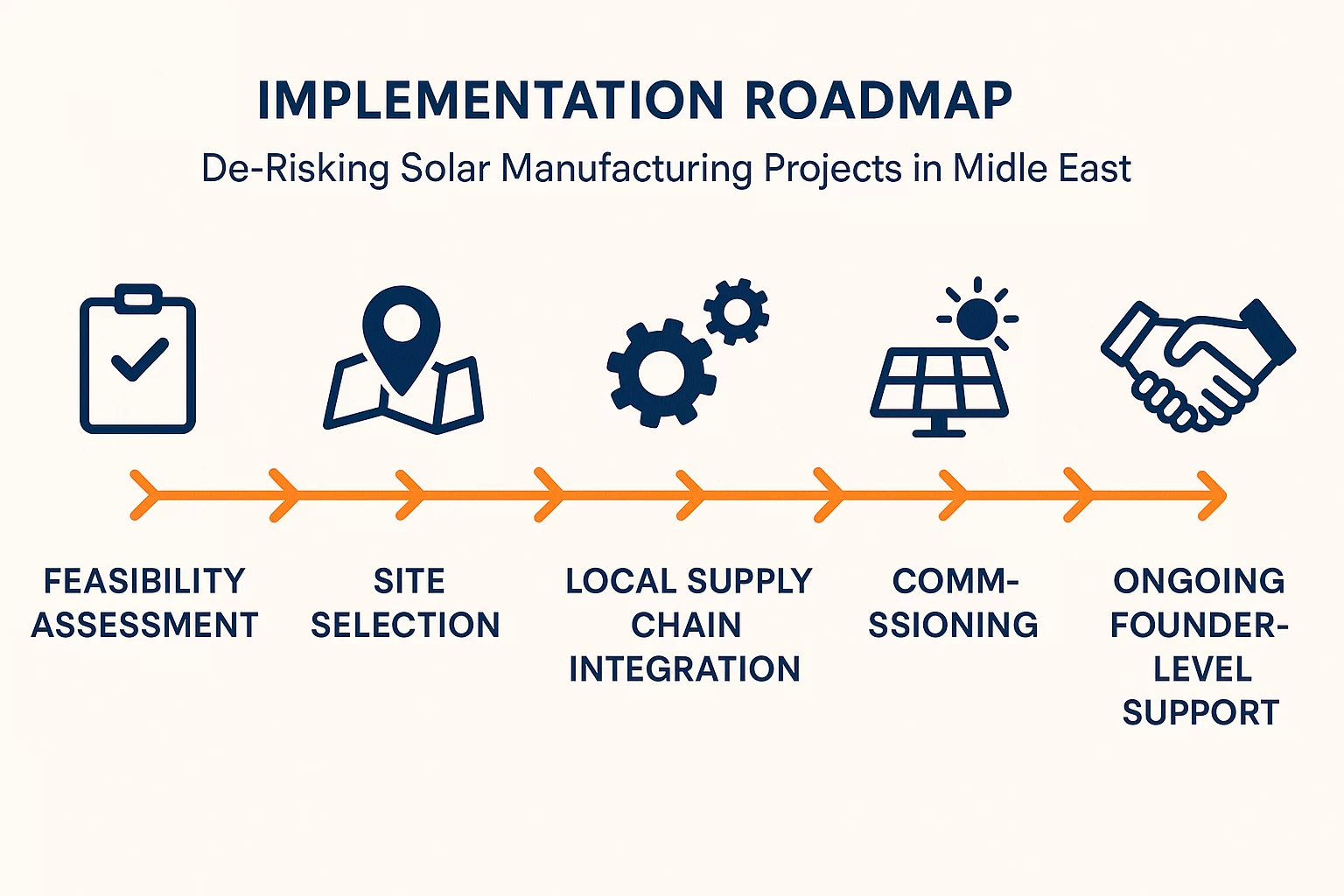

Technology alone is not enough. Success requires a partner who understands the entire journey, from initial concept to a fully operational, profitable factory. At J.v.G., you work directly with our founders—Hans, Patrick, and Andreas Thoma—who bring decades of real-world experience to your project.

Our partnership is built on a clear, structured process designed to eliminate uncertainty and build your confidence at every stage. We guide you through feasibility studies, factory layout design, equipment integration, and on-site commissioning. You bring the vision; we provide the technical and operational blueprint to make it a reality.

Frequently Asked Questions

Standard modifications are reactive fixes. DESERT Technology is a proactive, holistic system. We re-engineer everything from the machine level up—using more robust components, advanced process controls, and specialized sealing—to ensure the entire production line works in harmony with the environment, not against it. This prevents the cascading failures that simple cooling cannot address.

Our turnkey solution includes comprehensive on-site training for your local team. We don’t just deliver machines; we ensure your staff is fully capable of operating and maintaining the factory to our high standards. We stay until your team is confident and self-sufficient.

Yes. Our role as your partner extends beyond the production line itself. We assist with optimizing the factory layout for workflow efficiency and climate control. We also provide guidance on sourcing raw materials and establishing a resilient supply chain, drawing on our global network and 25+ years of experience.

Securing your investment starts with long-term operational reliability. A factory built with DESERT Technology will experience less downtime, lower maintenance costs, and higher production yields. Most importantly, it will produce modules with lower degradation rates, earning a reputation for quality and bankability that translates directly to a stronger, more profitable business.

Your Partner for Building a Lasting Value Chain

Building a solar manufacturing facility in the Middle East is a significant undertaking. The difference between a highly profitable venture and a failed project comes down to choosing a partner with proven, specialized expertise.

You are not just buying equipment. You are choosing a hands-on engineering team that will stand with you from concept to full-scale operation and beyond. We have guided entrepreneurs and industry leaders across the globe, and we are ready to help you build a lasting, operational value chain in one of the world’s most promising solar markets.

Let’s discuss how to make your solar manufacturing project a success. Contact our team to get started.