Global Reach:

Proven Results in Every Climate

Launching a solar module factory is a significant undertaking. Building one in a demanding climate is an even greater challenge. You are not just investing in machinery; you are building a foundation for regional energy independence, and you need a partner proven to deliver under the most strenuous circumstances.

Many equipment suppliers can quote a production line for an established market. Very few have the deep, field-tested experience required to guarantee success in the high-heat, high-dust environments of Africa, the Middle East, and other emerging solar economies. That experience is your greatest asset.

The Global Shift in Solar Manufacturing

For years, the solar manufacturing landscape has been heavily concentrated. According to the International Energy Agency (IEA), China’s share in all key manufacturing stages of solar panels now exceeds 80%. While this concentration has driven down global costs, it has also created significant supply chain risks for the rest of the world.

Forward-thinking investors and national leaders now recognize the strategic imperative to diversify. Building local manufacturing capacity is no longer just an economic opportunity—it is a matter of energy security and long-term stability. Your project is part of this critical global shift.

Focus Region Spotlight: Africa & the Middle East’s Untapped Potential

Nowhere is the opportunity for solar manufacturing more apparent than in Africa and the Middle East. The African continent holds an estimated 60% of the world’s best solar resources, yet it has only 1% of its installed solar capacity.

This gap represents a powerful opportunity for entrepreneurs like you. By establishing a local production facility, you can:

However, realizing this potential requires navigating a unique set of challenges absent from temperate European or Asian climates.

The Hard Truth: Overcoming Extreme Climate Challenges

A standard production line is not built to withstand the realities of a desert environment. To succeed, your factory and your final product must be engineered to overcome three primary adversaries:

- 1Extreme Heat: High ambient temperatures reduce the efficiency of solar cells and can accelerate the degradation of module components over time.

- 2Soiling from Dust and Sand: The accumulation of dust on a module’s surface is a critical issue. In some regions, soiling can reduce a panel’s daily energy output by over 1%—a significant loss that compounds day after day.

- 3Humidity and Corrosion: In coastal desert regions, the combination of heat, humidity, and salty air creates a highly corrosive environment that can damage module frames, junction boxes, and internal connections.

Ignoring these factors is the most common reason promising solar projects fail in challenging climates. A successful operation hinges on choosing technology specifically designed and proven to perform in these conditions.

The Solution: Choosing Your “Desert-Tested” Technology Stack

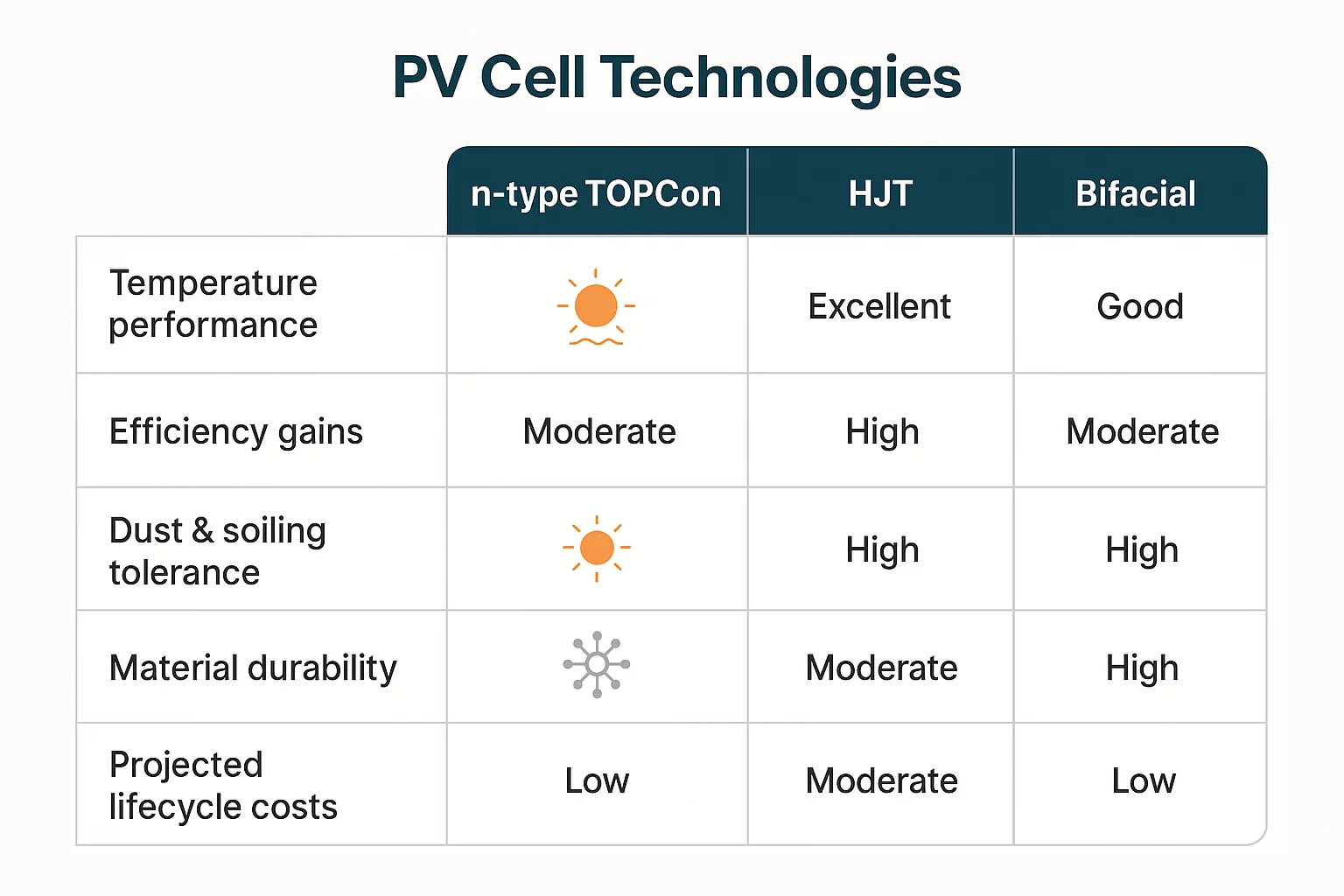

Your choice of technology is your first line of defense against the climate. We guide you in selecting a “Desert-Tested” production line, focusing on components and processes that ensure durability and high performance. This includes:

Choosing the right technology is a complex decision with long-term consequences. We provide the clarity you need to make the right choice for your specific location and business model.

Finding Your Partner: A Framework for Evaluating Turnkey Line Suppliers

Your choice of a turnkey supplier is the single most important decision you will make. This is not a simple equipment purchase; it is a long-term partnership that will determine the success and profitability of your venture.

A low initial price can be tempting, but it often hides the risk of poor support, unproven technology, and costly delays. We encourage you to evaluate any potential partner against a more rigorous set of criteria. A reliable partner must demonstrate:

Use this framework to assess any supplier you consider. It will help you see beyond the sales pitch and focus on what truly matters: securing the long-term viability of your investment.

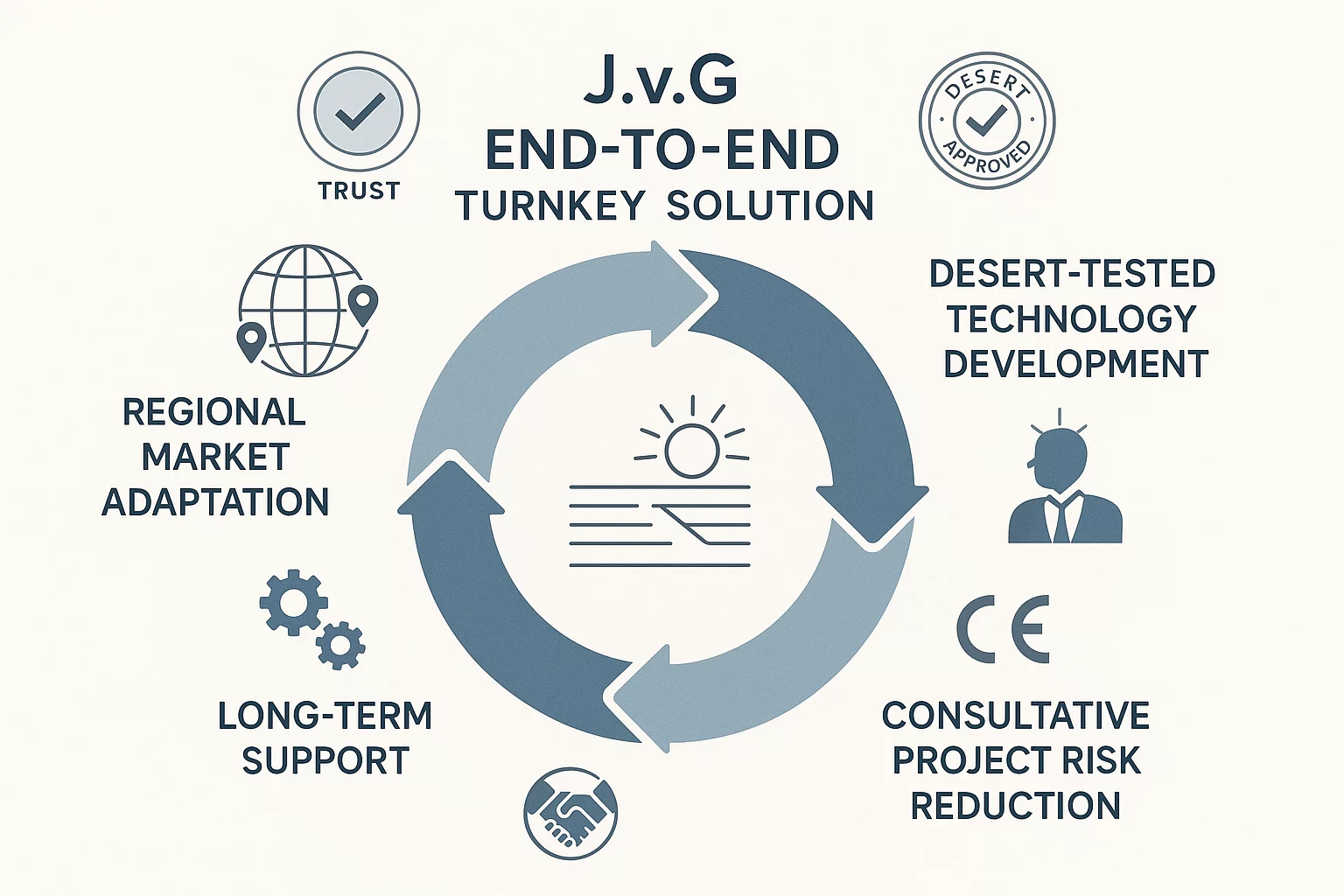

The J.v.G. Advantage: Proven Results in Every Climate

For over 25 years, J.v.G. technology GmbH has specialized in exactly this challenge: building successful, turnkey solar module factories in places others might deem too difficult.

Our expertise is best reflected in the plants we have already commissioned: Explore our case studies from the world’s harshest climates.

As a family-owned and operated engineering company, we offer something different. You are not dealing with a sales department; you are speaking directly with the founders and engineers who will design, build, and support your production line.

Our advantage is built on:

You bring the vision and the investment.

We bring the engineering expertise and partnership to make it a reality.

Frequently Asked Questions

Your strategic advantage is not competing on the global commodity market, but serving your local and regional markets. You can offer faster delivery, customized products, no import tariffs, and the powerful marketing advantage of a locally-made product. The goal is regional leadership, not global price competition.

You provide the core team; we provide comprehensive training. Our process is designed to transfer all necessary operational and maintenance knowledge to your local staff, ensuring you are fully self-sufficient. We remain your partners for ongoing support, but our goal is to empower your team to run the factory independently.

We design our lines with a modular approach. This means as cell technologies evolve (e.g., from TOPCon to next-generation cells), key stations in the production line can be upgraded or replaced without needing to rebuild the entire factory. This approach future-proofs your investment and allows you to stay competitive.

Our partnership does not end when production begins. We provide ongoing support, technical advice, and a reliable supply chain for spare parts to ensure your operation runs smoothly and efficiently for years to come. You are not just buying machines; you are gaining a partner invested in your long-term success.

Let’s Discuss Your Project

Your ambition to build a solar manufacturing facility in your region is the first step toward a more secure energy future. The next step is to speak with a partner who has the experience to guide you.

We are ready to listen to your vision and offer the honest, expert guidance you need.

Contact us to begin the conversation. Find your perfect solution.