From Factory to Full Operation:

Your Guide to Production, Delivery, and Installation

With your strategic planning complete, financial groundwork laid, and a clear vision for your solar module factory, you now face the most critical execution phase: turning blueprints and purchase orders into a tangible, operational asset.

This is the stage where logistical complexities, installation errors, and unforeseen delays can jeopardize a project’s timeline and budget. Many entrepreneurs discover too late that their equipment supplier isn’t an expert in global logistics, while their logistics partner doesn’t understand the technical nuances of the machinery.

At J.v.G., we eliminate this fragmentation. We believe the partner who designs your factory should be the one who ensures it is built, delivered, and commissioned flawlessly. This guide outlines our integrated approach, designed to carry you from equipment manufacturing to full-scale production with confidence and clarity.

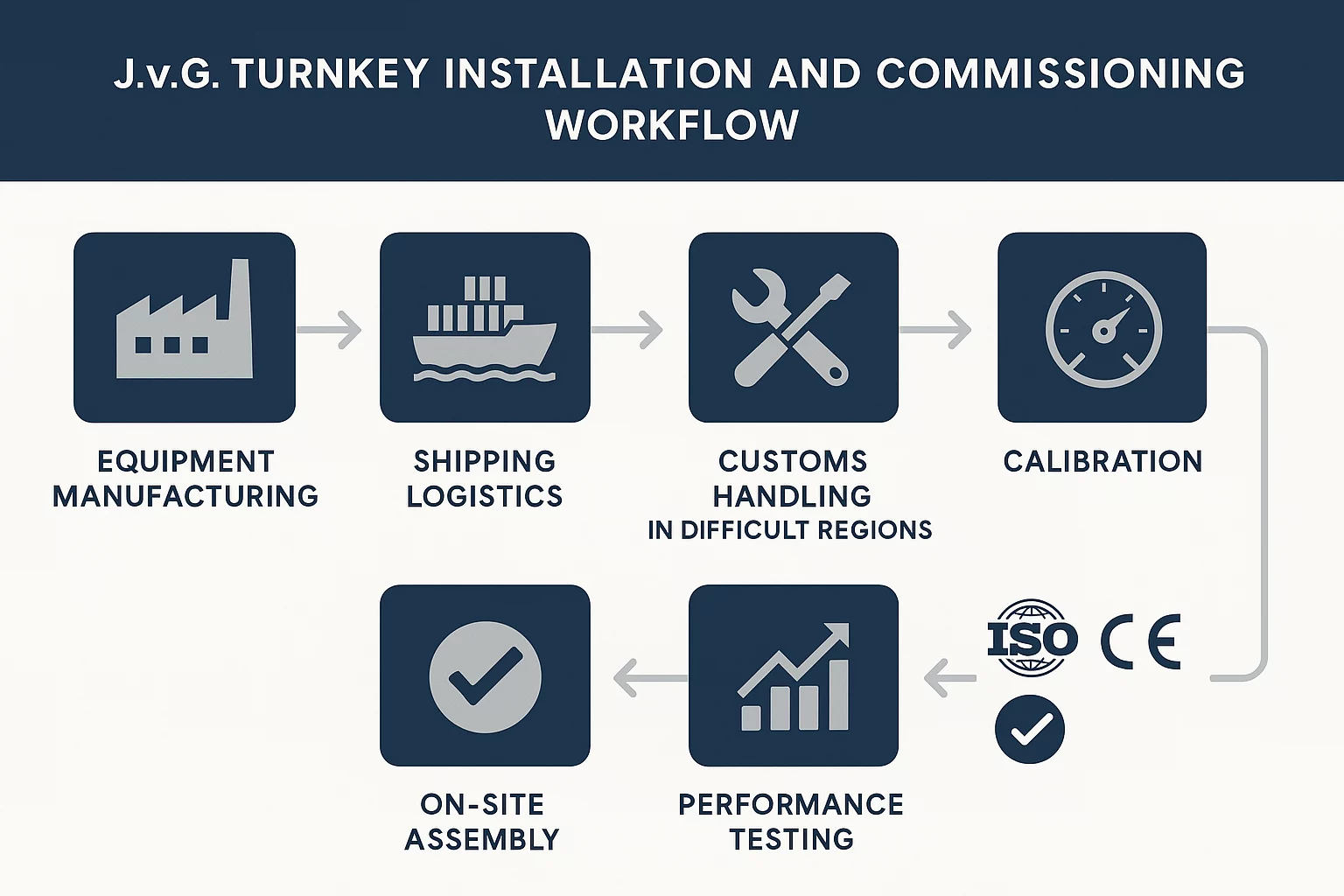

The J.v.G. Difference: An Integrated Turnkey Process

In an industry where multi-year lead times for new facilities are becoming common, a disjointed supply chain is a significant liability. The market is filled with equipment vendors and separate shipping companies, placing the burden of coordination—and the risk—entirely on you.

Our philosophy is different. For over 25 years, we have provided a single, accountable point of contact for the entire implementation process. You are not just buying machines; you are securing a commitment from our family to yours. We manage every detail, from building your custom production line in our German facility to the final handover of your operational factory.

Phase 1: Precision Manufacturing for Peak Performance

The reliability of your factory begins with the quality of its core components. We manufacture your production line in-house, ensuring every piece of equipment meets our exacting standards for durability and performance.

Our lines are engineered not just for today’s standards but for tomorrow’s possibilities. With modern production lines achieving cycle times of 45 seconds or less per panel, automation and efficiency are essential for profitability. We design your system for this level of performance, ready to handle the latest advances in solar technology, from high-efficiency cells to specialized modules for demanding environments.

Phase 2: Logistics & Delivery—Derisking Your Investment

The journey from our factory in Germany to your site is one of the highest-risk phases of any new solar venture. The industry faces significant challenges in coordinating oversized cargo, navigating complex customs regulations, and preventing damage to sensitive equipment. A single delay here can have cascading effects on your project’s launch date and return on investment.

We have built our reputation on successfully managing these challenges, especially for our partners in Africa, the Middle East, and other emerging markets. Our expertise isn’t just in shipping; it’s in project-managed logistics. We handle all documentation, coordinate every transfer, and assume full responsibility for delivering your factory equipment safely and on schedule. We have a proven track record of delivering where others cannot.

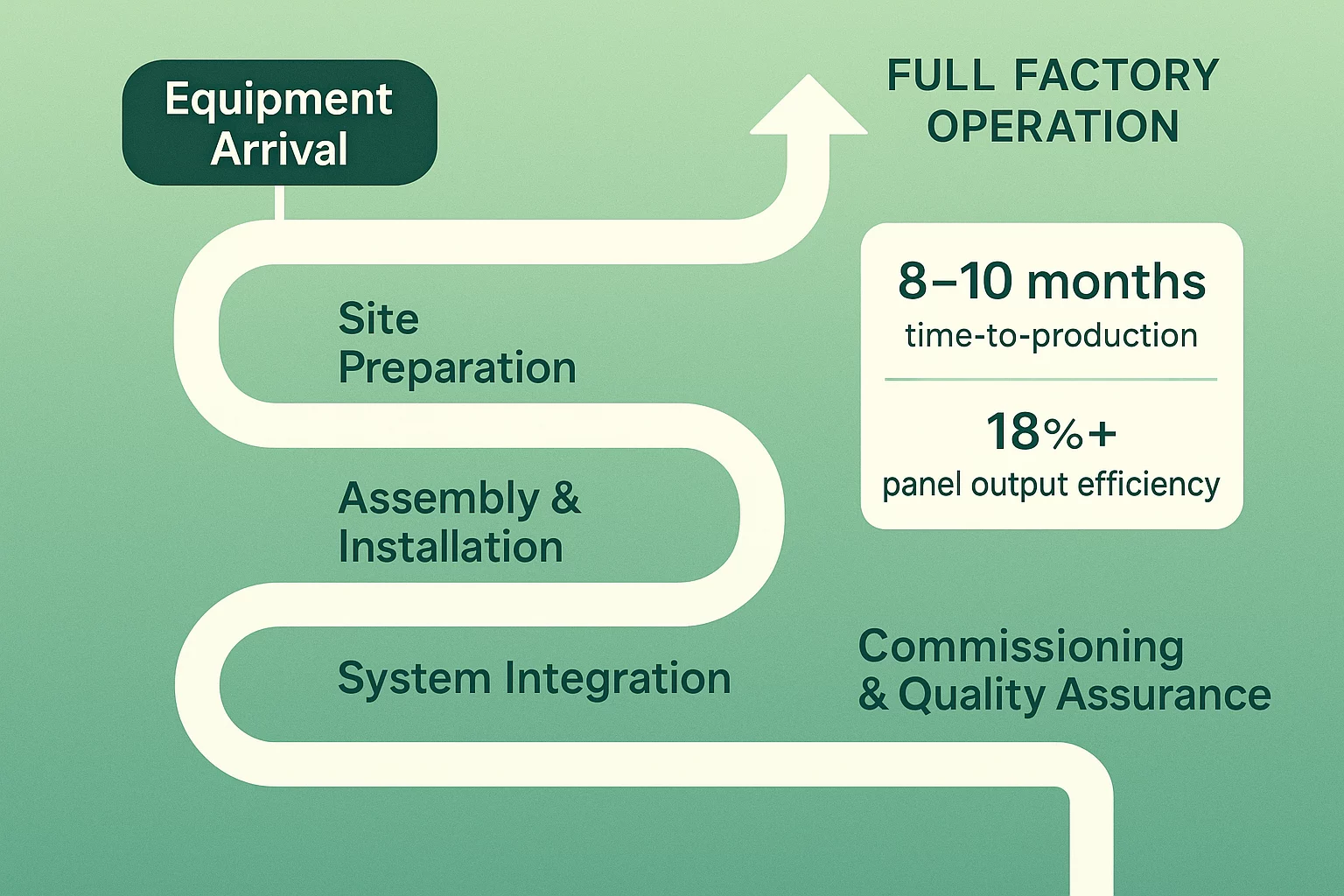

Phase 3: Installation & Commissioning – From Crate to Operation

Our commitment extends far beyond your factory’s doorstep. The arrival of the equipment marks the beginning of the final, crucial step: bringing your production line to life.

Our own experienced engineers travel to your site to oversee and execute the entire installation. This work is not outsourced to third-party contractors. The team that understands the intricate design of your machinery is the same one that assembles, calibrates, and tests it.

The process is systematic and transparent:

- 1Site Verification: We confirm that all preparations meet the technical requirements.

- 2Mechanical & Electrical Installation: Our engineers expertly assemble the production line.

- 3Commissioning: We run extensive tests to ensure every machine operates at peak efficiency and the line as a whole meets its guaranteed output.

- 4Team Training: We provide comprehensive, hands-on training for your local operators and maintenance staff, ensuring a smooth handover.

We remain on-site until your team is confident and your factory is fully operational, producing high-quality solar modules.

Your clear path to operational success—installation milestones and ROI insights that enable decisive action.

Case Studies: Proven Success in Challenging Environments

You are not the first entrepreneur we have guided through this process. For decades, we have supported investors and business leaders in establishing successful solar factories across the globe. Our process isn’t theoretical; it’s proven under the most demanding conditions.

From the intense heat of the Middle Eastern desert to the logistical complexities of remote African sites, we have delivered. These projects stand as a testament to the reliability of our equipment and the resilience of our integrated approach.

Trust our proven turnkey process—engineered for flawless delivery and installation, no matter the complexity.

Frequently Asked Questions

As you evaluate potential partners, it’s vital to ask direct questions about this critical phase. Here are our answers to the questions we hear most often.

While every project is unique, our integrated model is designed to prevent the common delays that plague fragmented supply chains. By managing manufacturing, logistics, and installation as a single, cohesive process, we maintain control over the timeline and provide you with clear, predictable milestones.

The primary risks are equipment damage, customs delays, and transportation issues. We mitigate these through:

Yes. Our own J.v.G. engineers—not third-party contractors—are on-site to manage the entire installation, commissioning, and training process. We believe this is the only way to guarantee a successful outcome.

Our goal is your long-term success. The handover includes comprehensive training for your staff. Beyond that, you gain a partner who remains available for support, spare parts, and future consultation. To us, you are not just a past project; you are part of the J.v.G. global family.

Your Project, Our Commitment

Choosing a partner to build your solar factory is one of the most important business decisions you will make. You need more than an equipment list and a shipping quote. You need a trusted, experienced team that will stand with you from start to finish.

Likewise, you bring the vision and the ambition. We provide the proven process, technical expertise, and unwavering commitment to see it through.

Ready to turn your vision into a fully operational factory? Let’s discuss the specifics of your project.