Deciding on the right level of automation for your solar module factory is one of the most critical investment decisions you will make. This is more than a simple choice between machines and manual labor—it’s a strategic decision that defines your factory’s throughput, quality, operating costs, and long-term resilience. While many in the industry present this as a simple choice, the reality is far more nuanced.

This guide offers a clear framework for making that decision. We move beyond general benefits to explore how specific production volumes and business goals should dictate your automation strategy. Our aim is to equip you with the insights needed to confidently choose the right path for your project.

The Spectrum of Automation in PV Manufacturing: Manual, Semi-Automated, and Fully-Automated

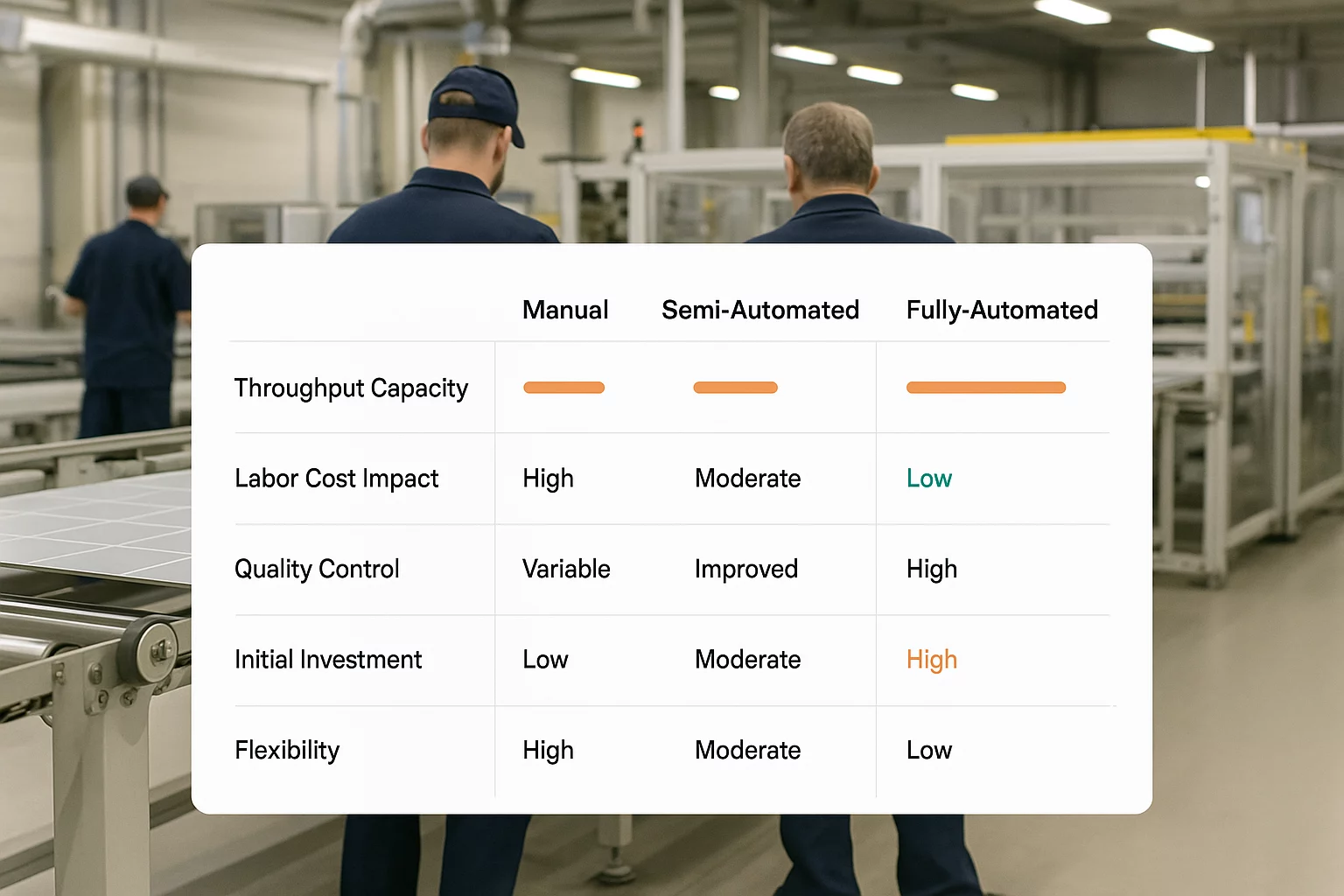

Understanding the distinct capabilities of each production philosophy is the first step. Each level offers a different balance of capital investment, operational flexibility, and production scale.

-

Manual Production: Relies entirely on skilled operators for processes like cell stringing, layup, and framing. This approach offers the lowest initial investment and maximum flexibility for small-scale or specialized production runs, but it is highly dependent on operator skill, which can lead to quality inconsistencies and significantly limits throughput.

-

Semi-Automated Production: This hybrid model automates critical or repetitive tasks while others remain manual. For example, automatic stringers ensure consistent cell soldering, while layup and bussing may be done by hand. This approach strikes a strategic balance, improving quality and speed in key areas without the capital expenditure of a fully automated line.

-

Fully-Automated Production: In this model, robotic systems and conveyors handle the entire process from cell loading to final packing with minimal human intervention. This requires the highest initial investment but delivers unmatched throughput, consistency, and process control. Data from each stage is captured automatically, enabling sophisticated quality management and optimization.

The Capacity Threshold: How Production Volume Dictates Automation Strategy

Your target annual production capacity is the single most important factor in determining the right level of automation. The economics and operational realities of a 50 MW factory are fundamentally different from those of a 500 MW gigafactory.

The 50 MW Factory: The Case for Strategic Semi-Automation

For entrepreneurs and investors entering the market with a target capacity of around 50 MW, a semi-automated line often represents the most intelligent investment. At this scale, the goal is to achieve professional, repeatable quality and respectable throughput without the immense capital cost of full automation.

By automating the most sensitive steps—such as cell stringing and lamination—you secure the core quality of your modules. Other steps, like layup and framing, can be managed efficiently by a well-trained team. This approach allows you to build a resilient business with a faster path to profitability and the flexibility to adapt to changing market needs, offering a pragmatic path focused on immediate ROI and sustainable growth.

The 500 MW Gigafactory: The Necessity of Full Automation

When your business model requires gigawatt-scale production, full automation is no longer an option—it is a necessity. To compete at this level, you must achieve the lowest possible cost-per-watt, and that requires immense speed and precision. Fully automated lines can process up to 3,600 wafers per hour, a rate impossible to sustain manually.

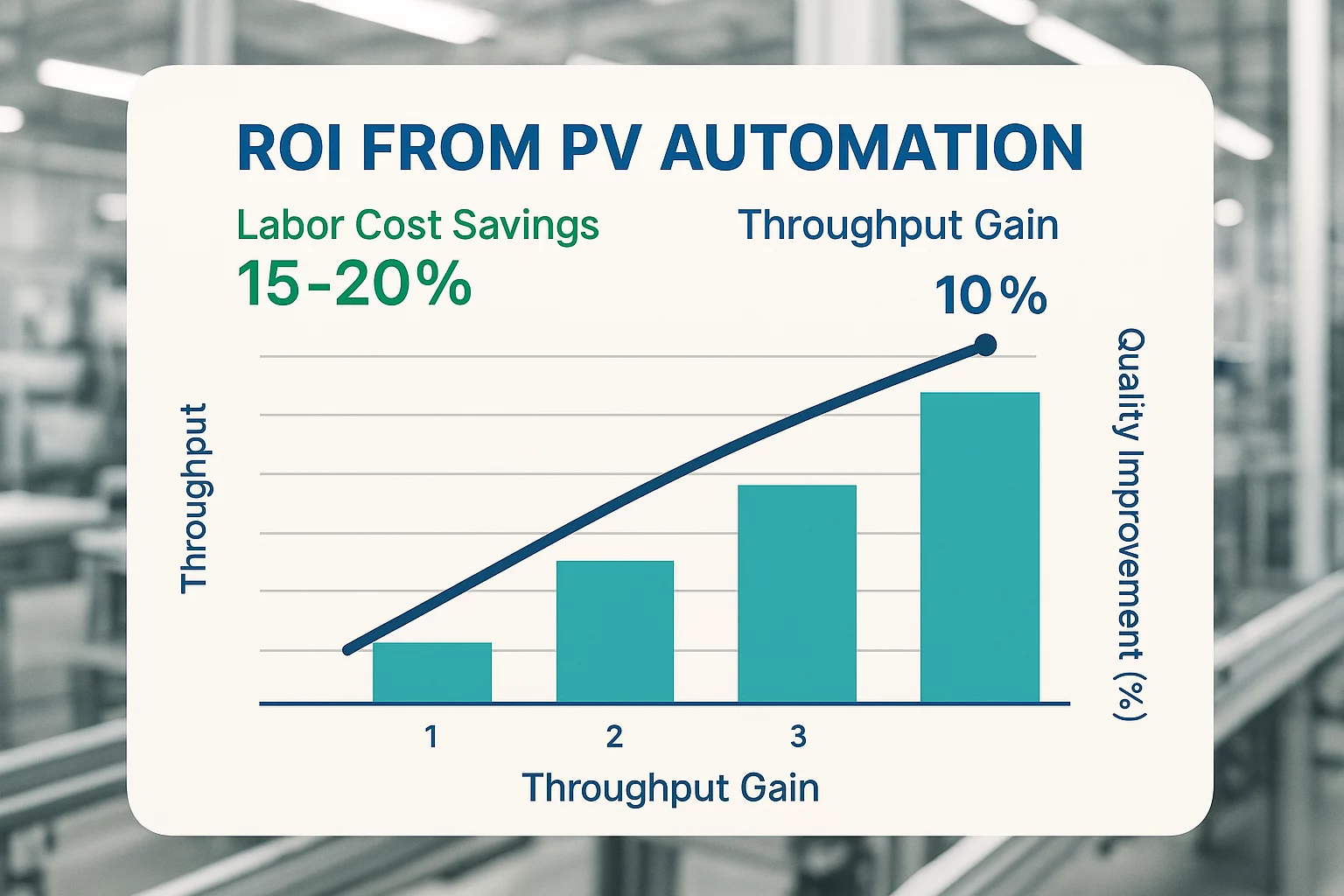

Furthermore, the process control required at this scale can only be achieved through automation. With every variable monitored and every module’s history logged, the line ensures a degree of quality control that is statistically perfect. Projections suggest automation can lower PV module production costs by 15–20% by 2028, making it the definitive standard for any large-scale operation.

A Deeper Dive: Overlooked Technical Details in PV Automation

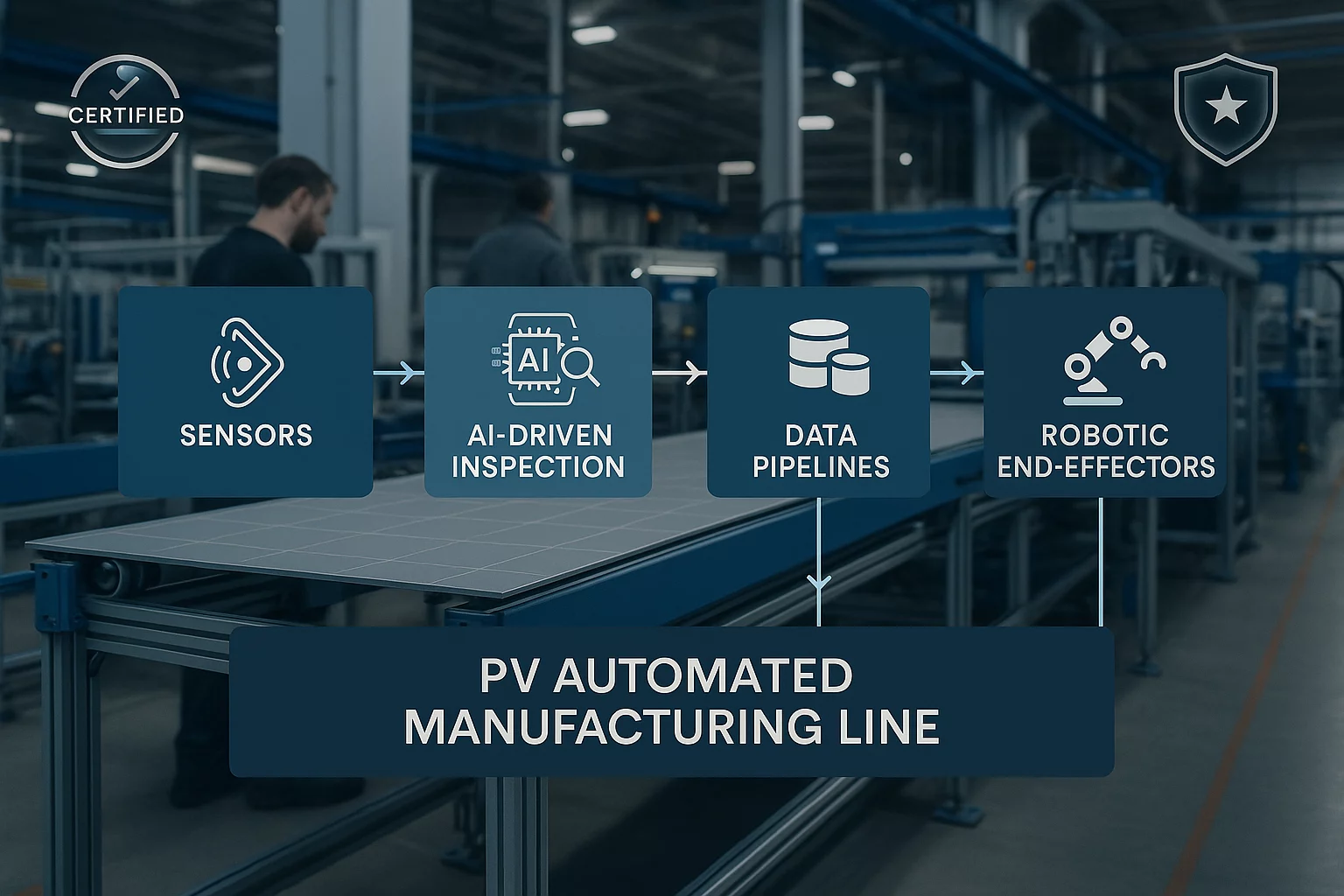

A successful automated line is more than just a collection of robots. True reliability comes from the thoughtful integration of often-overlooked technical systems. The quality of your sensor arrays, the efficiency of your data processing pipelines, and the design of your robotic end-effectors (the “hands” of the robot) are what separate a high-performance factory from one that constantly struggles.

For example, advanced machine vision systems using AI can inspect for microcracks far more reliably than the human eye. Precise sensor integration ensures every robotic movement is exact, preventing cell damage and material waste. These are precisely the details our complete turnkey solutions are built upon, refined over decades of real-world experience.

Financial Modeling for Automation: Calculating Your True ROI

The financial case for automation extends far beyond the initial purchase price. A proper ROI calculation accounts for the total impact on your business, including:

- Reduced Labor Costs: Fewer operators are needed per MW of output.

- Increased Throughput: More modules produced in the same amount of time.

- Improved Material Yield: Precision robotics minimize cell breakage and material waste.

- Higher Quality & Bankability: Consistent production quality leads to better module performance, higher selling prices, and stronger investor confidence.

When these factors are considered, the investment in automation reveals a clear and compelling return, securing the factory’s long-term financial health.

De-Risking Your Investment: A Checklist for Choosing an Automation Partner

Your choice of equipment supplier is as important as the equipment itself. You aren’t just buying machines; you are choosing a partner who will be critical to your success for years to come. This partner must have proven engineering expertise, a deep understanding of the reliability of our technologies, and a commitment to long-term support.

Before making a final decision, consider asking any potential partner:

- How many production lines have you successfully commissioned in our target region?

- What does your process for operator training and knowledge transfer look like?

- What level of ongoing technical support and spare parts availability can we expect after the factory is running?

- Can you provide a detailed plan for future upgrades and scalability?

A trustworthy partner will welcome these questions and provide clear, verifiable answers.

Frequently Asked Questions About PV Automation

What is the typical payback period for a semi-automated line?

While this varies with local labor costs and energy prices, many of our clients with semi-automated lines see a payback period of 3 to 5 years, driven by increased throughput and improved module quality.

Can a manual line be upgraded to semi-automated later?

Yes, a modular approach is possible and often recommended. We can help you design a manual line with a layout that anticipates the future integration of automated equipment, allowing you to scale your investment as your business grows.

How does automation impact workforce requirements?

Automation shifts the need from a large number of manual laborers to a smaller, more highly-skilled team of technicians, engineers, and quality control specialists. A key part of our service is providing the comprehensive training to build this team.

Beyond cost, what is the single biggest advantage of full automation?

Data. A fully automated line generates a massive amount of precise data from every step of the manufacturing process. This data is invaluable for process optimization, predictive maintenance, and providing absolute traceability for every module you produce—a powerful advantage in the market.

Your Project, Your Strategy

The right automation strategy is the one that aligns with your specific production targets, budget, and long-term business vision. Whether your correct path is a flexible semi-automated line or a high-throughput fully automated factory, the decision requires careful consideration and expert guidance.

We have supported entrepreneurs and industry leaders across the globe in navigating this process. Our focus is on understanding your unique goals to design a solution that is not only technologically sound but also commercially successful.

Let’s discuss the right automation strategy for your project. Contact our team for a consultation.