Beyond the Turnkey:

Building a Resilient Solar Factory for Asia’s Dynamic Markets

Asia’s solar sector offers an undeniable opportunity. With a market projected to reach $1.08 trillion by 2034 and growing at a remarkable 25.31% annually, the incentive to build local manufacturing capacity has never been stronger. Yet, this explosive growth comes with significant challenges: shifting government policies, intense competition, and the constant evolution of solar technology.

In such a volatile environment, a standard turnkey production line isn’t just an investment—it’s a risk. You need more than a set of machines; you need a strategic framework for a resilient, future-proof manufacturing operation that can adapt as quickly as the market does. This is a guide to building that factory.

The Flaw in Standard Turnkey Solutions for Asian Markets

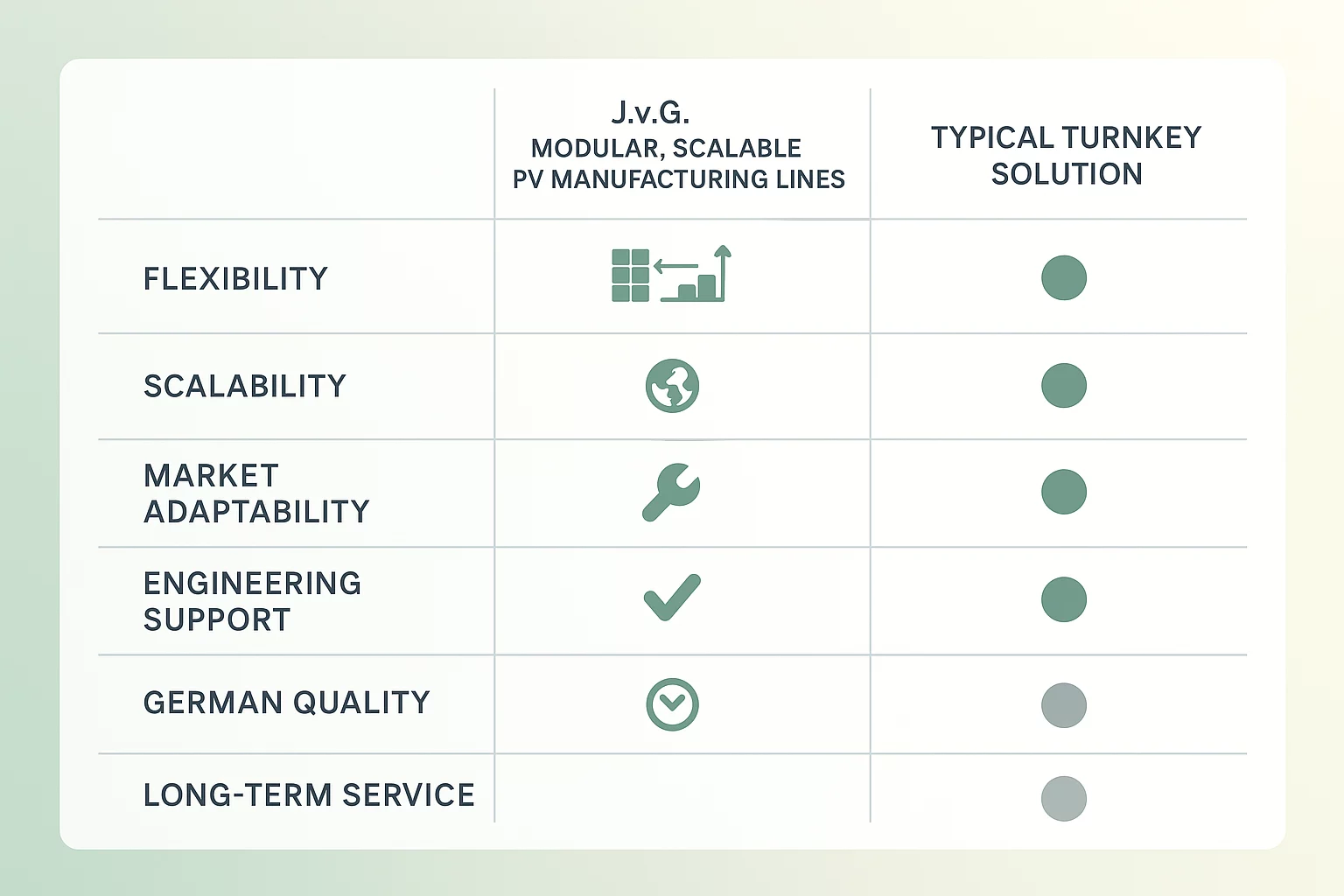

Many equipment providers offer pre-packaged, one-size-fits-all production lines. While appealing in their simplicity, these rigid systems are fundamentally unsuited for the Asian market. Engineered for a static environment, they are vulnerable to the very factors that define the region’s dynamism.

A rigid line cannot easily adapt when a new, more efficient cell technology like TOPCon or HJT becomes standard. Nor can it be reconfigured to meet changing local content requirements or capitalize on new government incentives, such as India’s $1.8 billion Production Linked Incentive (PLI) scheme.

This inflexibility leads to costly downtime, premature obsolescence, and a lost competitive edge. You risk being locked into yesterday’s technology while your competitors pivot to meet tomorrow’s demand.

Our Philosophy: Engineering for Adaptability

For over 25 years, we’ve approached factory design not as a product sale, but as a long-term engineering partnership. Our philosophy is built on two core principles designed to navigate uncertainty: modularity and scalability.

Modularity

We design your production line as a series of interconnected, independent modules—from cell processing and stringing to lamination and testing. This approach delivers strategic flexibility. When a new technology emerges, you don’t replace the entire line. You simply upgrade a single module, preserving your initial investment while keeping your factory on the cutting edge.

Scalability

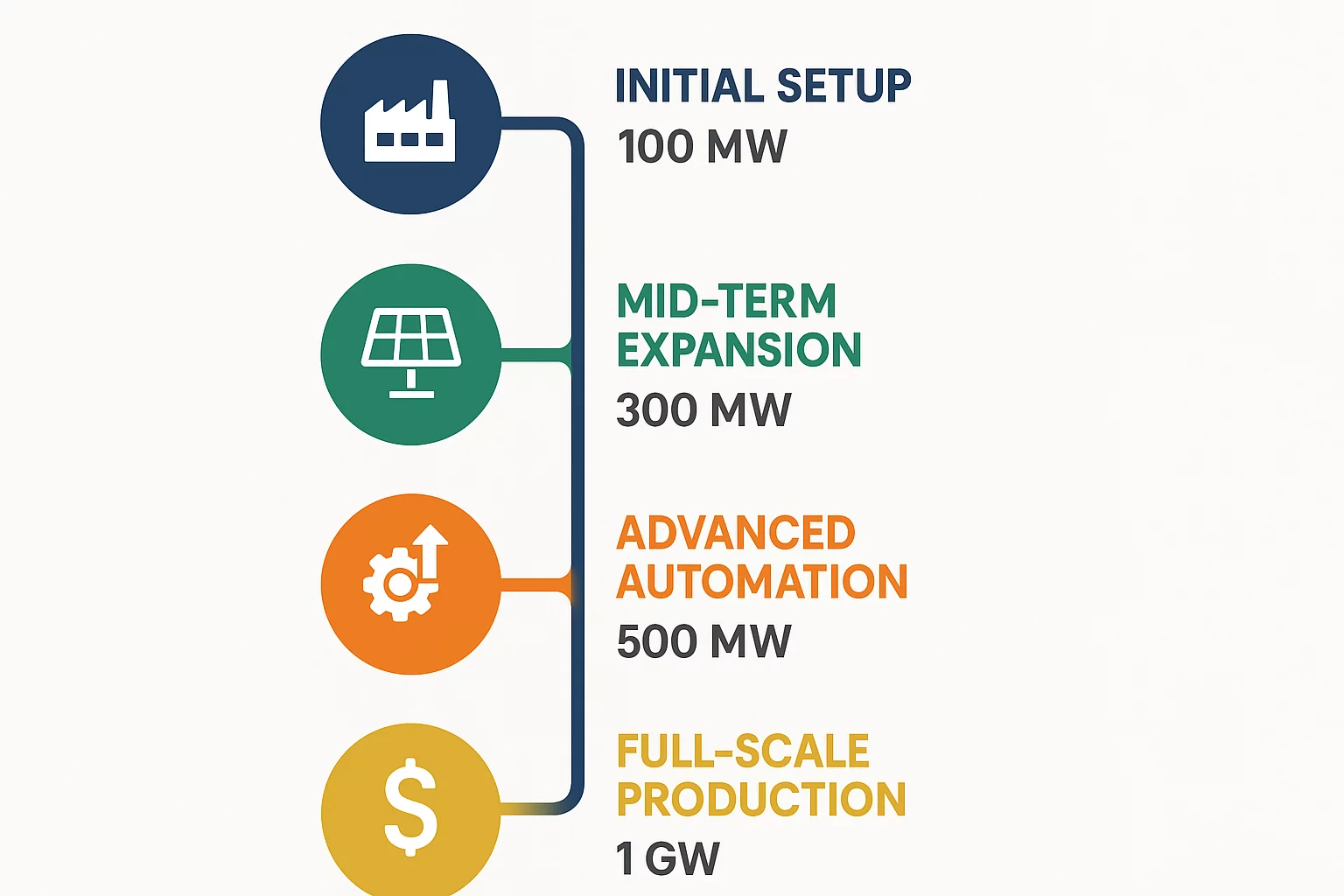

You can begin with a production line that fits your current capacity and market demand—a 100 MW line, for example. As your business grows, our modular design lets you seamlessly add capacity without disrupting existing operations. This phased approach de-risks your investment and allows your factory to grow in step with your success.

This isn’t just about supplying machines. It’s about providing a robust engineering framework that ensures your business remains competitive and profitable for the long term.

A Tailored Approach for Diverse Asian Markets

Asia is not a single market. The strategic needs of an entrepreneur in India are vastly different from those of an investor in Southeast Asia. A successful factory demands an engineering plan that reflects these local realities.

Our role is to understand your specific market and business goals, then engineer the precise solution to match.

Why German Engineering is Your Most Valuable Asset in Asia

In a market where the global solar PV manufacturing equipment sector is growing at a 23.1% CAGR, your choice of engineering partner is your most critical decision. The “Made in Germany” label on our solutions is more than a mark of origin; it’s a promise of reliability, precision, and long-term value.

German engineering ensures your production line is built to last, minimizing downtime and maximizing your return on investment. It translates to robust design, superior components, and an attention to detail that delivers consistent, high-quality output.

Most importantly, when you work with J.v.G., you aren’t dealing with a large, impersonal corporation or a regional sales agent. You have a direct line to our founding family and lead engineers. We become your partners, personally invested in guiding you from the initial concept to full-scale operation and beyond.

Your Scalability Roadmap: From 100MW to 1GW

Entering the solar manufacturing business shouldn’t require a massive, high-risk investment from day one. Our modular approach provides a clear, manageable path to growth, allowing you to start with a foundational production line and scale your capacity as you secure market share and generate revenue.

This roadmap isn’t just a concept; it’s a concrete plan we develop with you, outlining the technical steps, investment milestones, and operational upgrades needed to take your factory from an initial 100MW to 500MW, 1GW, and beyond.

Frequently Asked Questions

This is the core strength of our approach. Instead of a single, rigid system, your line is composed of distinct modules. When you decide to adopt a new cell technology like TOPCon, you only need to upgrade or replace the relevant modules, such as the cell stringer. The rest of your line—including lamination and testing equipment—remains fully functional. This approach saves significant capital and enables a much faster transition, keeping you competitive.

The initial investment for a modular line is comparable to that of a high-quality turnkey system. The true financial benefit, however, lies in the total cost of ownership. The flexibility to upgrade and scale incrementally prevents the massive expense of replacing an entire obsolete line in the future. Moreover, the superior reliability of German-engineered components reduces costly downtime, creating a more profitable operation over the long term.

Our relationship doesn’t end when the power is turned on. You aren’t just buying machines; you are gaining a long-term partner. We provide comprehensive training for your team, ongoing technical support, and strategic advice as you plan future expansions or upgrades. You will always have direct access to our experienced engineers who understand your specific setup and business goals.

Don’t Just Buy a Production Line. Invest in a Production Partner.

In Asia’s dynamic solar market, success depends on the ability to adapt. Choosing a manufacturing partner who provides a flexible, scalable, and reliable engineering foundation is the most critical decision you will make. You bring the vision and the ambition; we provide the engineering expertise and steadfast support to make it a reality.

Let’s discuss the specific needs of your project and market. Contact our engineering team to begin planning your resilient solar factory.