Solar Manufacturing in Africa:

From High-Risk Mirage to Profitable Reality

The opportunity for solar energy in Africa is immense. For investors and entrepreneurs, however, the path to establishing a successful solar panel production facility is a complex undertaking.

High-level reports point to the potential, but they offer little practical guidance. Local consultants may understand regulations but often lack the global engineering and supply chain experience required for a project of this scale. This leaves you, the decision-maker, caught between a promising vision and a landscape of considerable risk.

You don’t need a simple equipment supplier. You need a partner with proven experience navigating the unique challenges of emerging markets—a partner who can transform a high-stakes investment into a secure, profitable, and lasting asset. For over 25 years, this has been our work.

The Manufacturing Landscape in Africa: A Reality Check

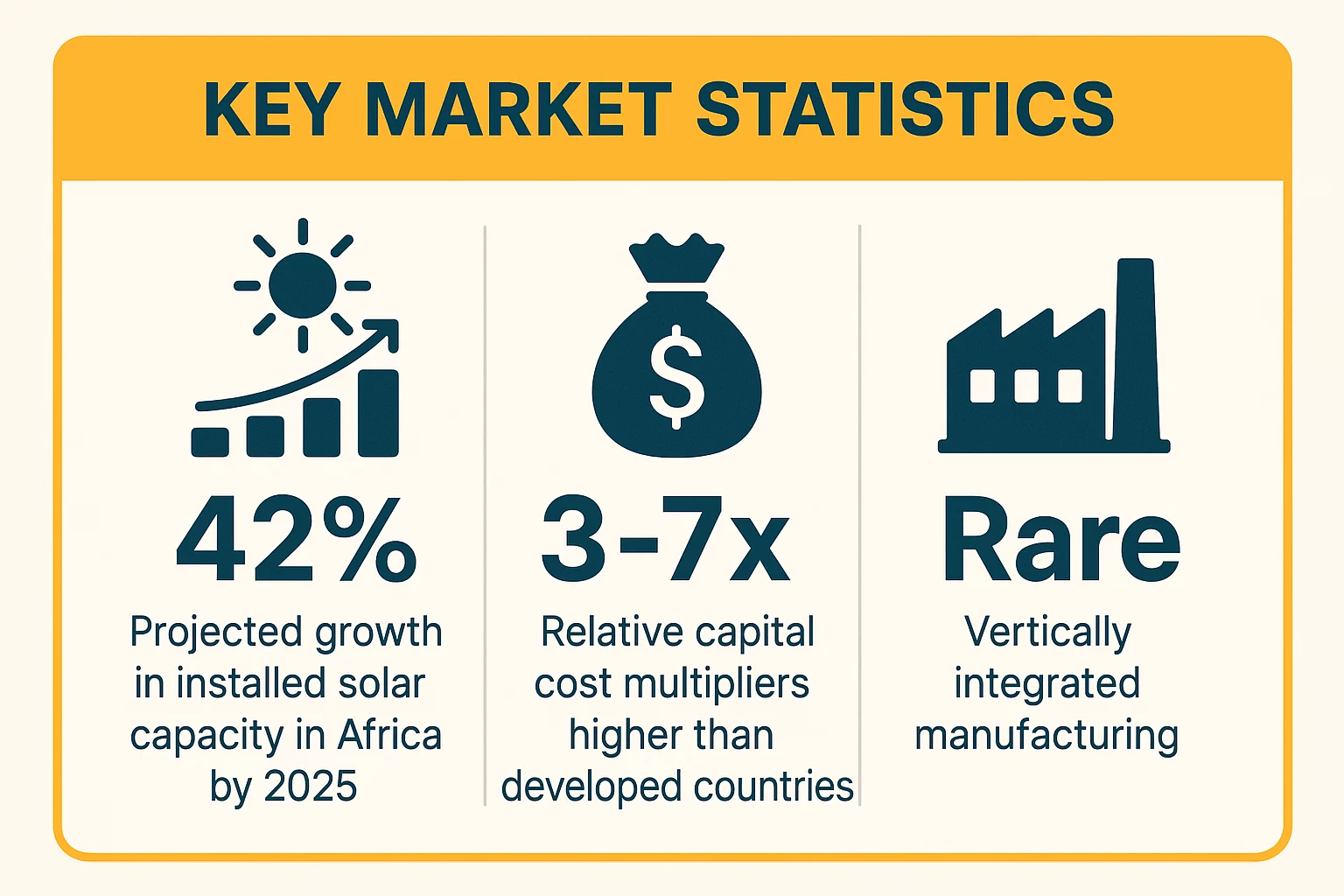

A sound investment begins with understanding the true state of the market. Projections from the International Energy Agency (IEA) show Africa’s installed solar capacity is set to increase by an impressive 42% by 2025, signaling a clear and urgent demand.

However, a closer look reveals a critical challenge. Reports from institutions like the Africa Policy Research Institute confirm that most of what passes for “manufacturing” on the continent is currently limited to the final assembly of imported components.

True, vertically integrated manufacturing is exceptionally rare. This is largely due to high capital costs—which can be three to seven times higher than in developed nations, according to SEforALL—and significant logistical hurdles.

This gap between assembly and genuine production is where your opportunity lies, but it is also where the risks are highest. Success requires a strategy grounded in reality, not just potential.

Why Most Solar Projects in Emerging Markets Fail (And How Yours Can Succeed)

An investment of this scale isn’t about buying machines; it’s about mitigating risk. Many ventures falter not because the vision was wrong, but because their planning underestimated the realities of operating in such demanding environments. The fear of costly, avoidable mistakes is justified.

We have spent decades guiding partners through these challenges. Here are the most common pitfalls—and the framework we’ve developed to ensure your project succeeds where others have not.

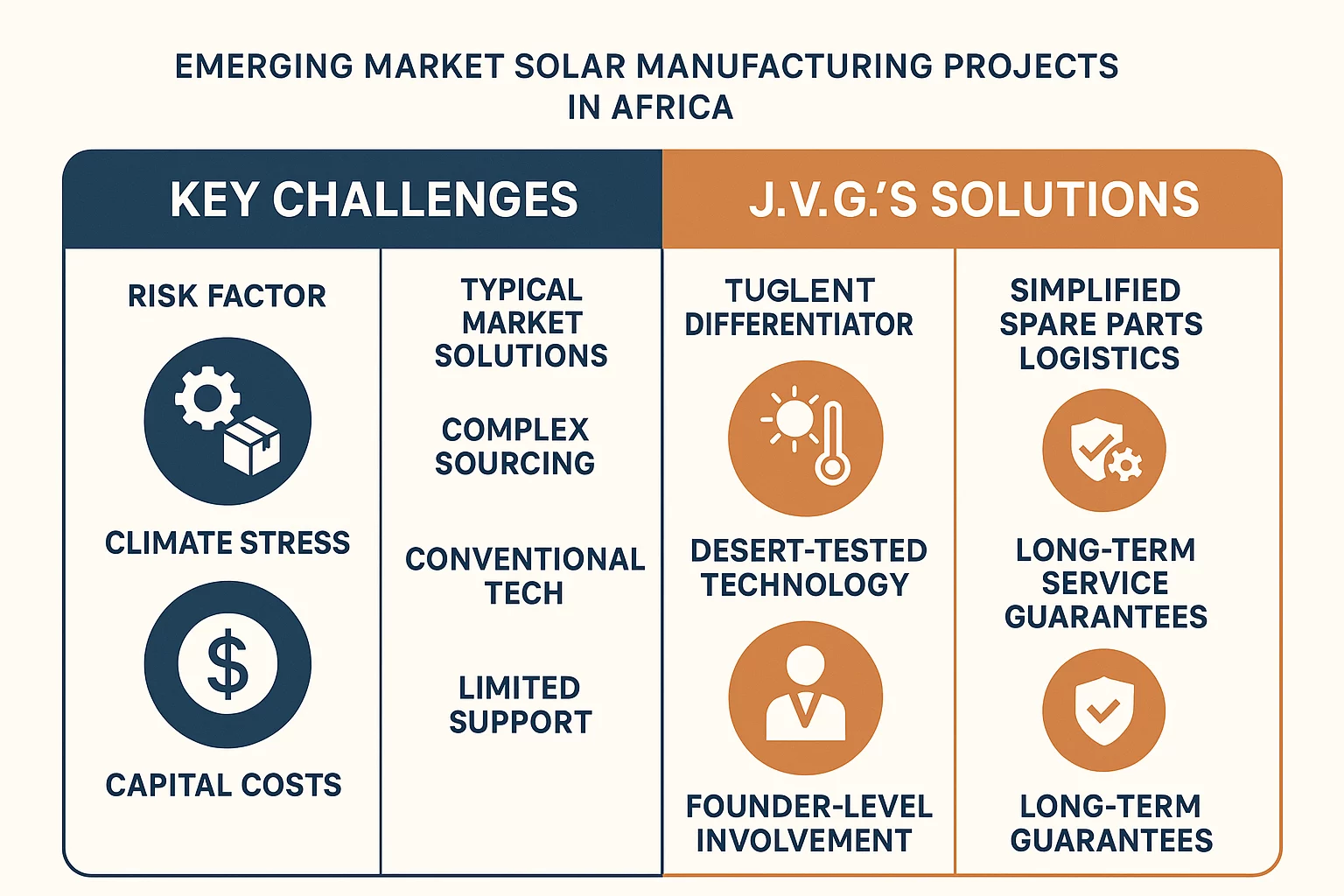

Common Risk 1: Underestimating Climate Stress

Standard solar panels are not designed for the extreme heat, UV radiation, and abrasive dust common in many parts of Africa. This leads to rapid degradation, lower-than-expected output, and ultimately, a failed business case.

The J.v.G. Solution 1: DESERT-Tested Technology

We build your production line to manufacture modules specifically engineered for harsh climates. This core engineering principle guides our selection of every component, ensuring durability where it matters most.

Common Risk 2: The Spare Parts Nightmare

A simple component failure can shut down an entire production line for weeks or even months when you’re dependent on complex international supply chains. Transactional equipment suppliers often disappear after the sale, leaving you to manage the crisis alone.

The J.v.G. Solution 2: Simplified Logistics and Robust Design

Our lines are designed for resilience and easy maintenance. From day one, we establish a streamlined logistics plan for critical spare parts and train your local team to handle most service issues independently, maximizing uptime.

Common Risk 3: The Partner-Supplier Disconnect

You might hire consultants for strategy and suppliers for machines, but no single entity takes responsibility for the project’s ultimate success. When problems arise, accountability is fragmented, leaving you to bridge the gap.

The J.v.G. Solution 3: Founder-Level Partnership from Day One

When you work with J.v.G., you work directly with our founders—Hans, Patrick, and Andreas Thoma. We become your single point of contact and accountability, from the initial business plan to full-scale production and beyond.

Technology Showcase: Engineering for the World’s Harshest Climates

In a European market, a few percentage points of performance loss from heat might be acceptable. In Africa, it can be the difference between a profitable venture and a failed one. This is why our technology focus isn’t on trends, but on resilience.

Our “DESERT-tested” philosophy rests on proven technologies that deliver superior performance in high-temperature environments. We design production lines capable of implementing modern cell architectures like HJT and TOPCon, which are documented to perform better in extreme heat.

We also focus on the entire module construction, advising on special encapsulants and backsheets that resist UV degradation and prevent issues like Light and elevated Temperature Induced Degradation (LeTID). Your factory won’t just assemble panels; it will produce highly durable energy assets, engineered for decades of reliable performance in your specific climate.

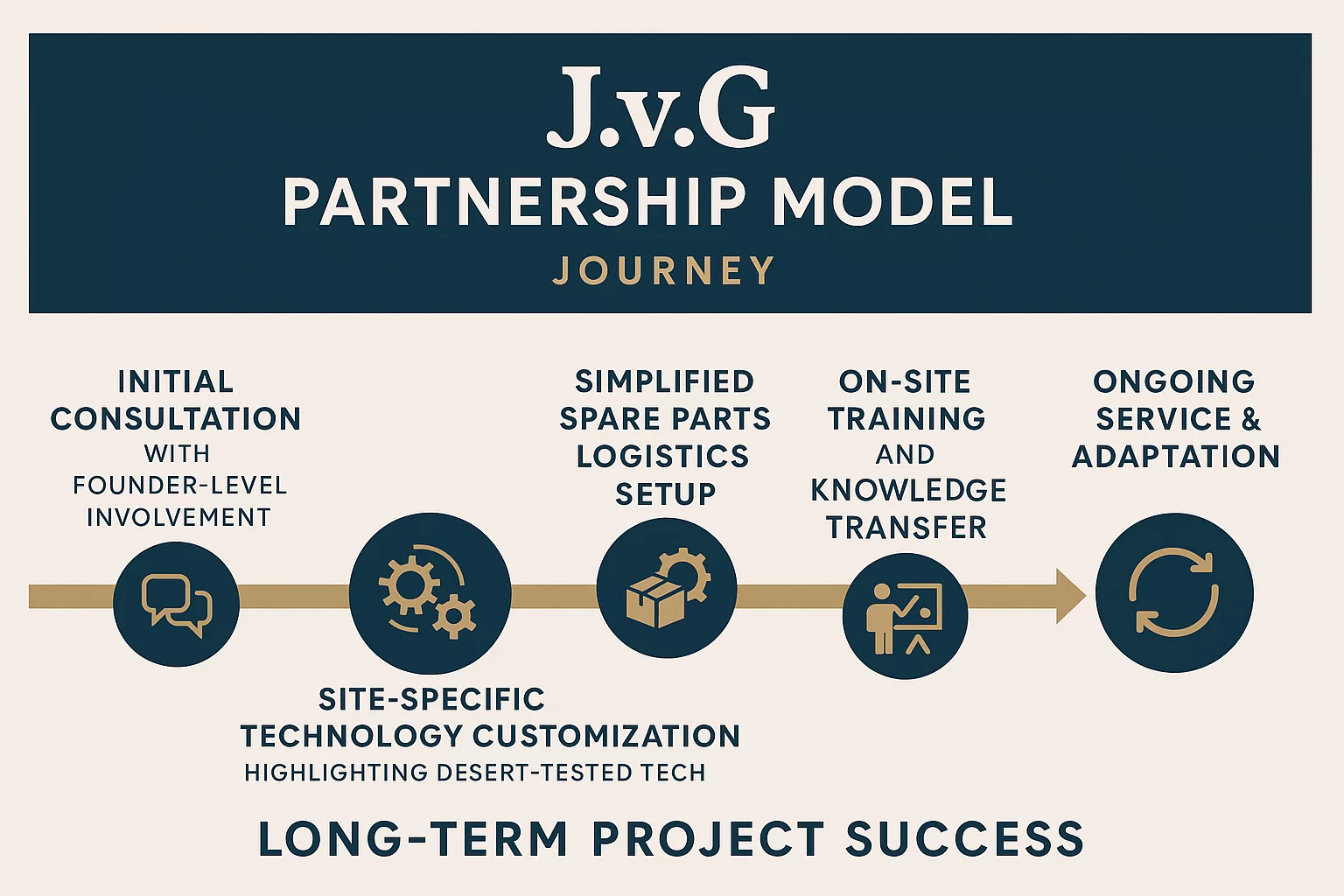

The J.v.G. Partnership Model: Your De-Risking Framework

You bring the vision and the investment. We provide the comprehensive technical and operational partnership to make it a reality. We have refined our process over dozens of successful projects in emerging markets to ensure clarity, accountability, and hands-on support at every stage.

This is not a transaction. It is a long-term collaboration built on trust and shared success.

Our partnership includes:

Case Study: Real-World Partnership in Action

Real-world success is the only metric that matters. For one of our partners in the Middle East—a region with climate and logistical challenges similar to many parts of Africa—a critical shipment of raw materials was delayed at port for weeks. A typical equipment supplier would have considered this an external problem.

For us, it was our problem.

Using our global logistics network and direct relationships, our team intervened to help resolve the customs issue. Simultaneously, our engineers on-site recalibrated the initial production run to maximize the use of existing materials, preventing in a a costly way full-scale shutdown. That is the difference between a supplier and a partner. This level of commitment is how we protect your investment.

Frequently Asked Questions

A consultant provides advice. We build your factory with you. Our role combines strategic consulting with hands-on engineering, project management, and long-term operational support. We take responsibility for the outcome, not just the recommendation.

Our strategy is twofold. First, we design our lines with robust, reliable components to minimize failures. Second, we create a simplified logistics and spare parts plan from the start, ensuring you have critical components on hand. Most importantly, we train your local staff extensively, empowering them to become your first line of defense.

The right approach depends entirely on your business case, local resources, and long-term goals. For many partners, starting with a semi-automated assembly line is the most prudent path, as it lowers initial capital costs. We help you analyze this decision and can design a factory that allows for future integration and expansion as your business grows.

The first step is a direct conversation. We believe major projects require human connection, not forms. When you contact us, you will have the opportunity to speak directly with our founders to discuss your vision in confidence.

Build Your Solar Future on a Foundation of Trust

Entering the solar manufacturing market in Africa requires more than capital. It demands a partner who has navigated this terrain before, who deeply understands the risks, and who is committed to your long-term success.

For over 25 years, we have been that partner for leaders and investors across the globe. We don’t just supply equipment; we build legacies.

Let’s discuss your vision. Contact us for a direct, confidential consultation with our founders.