Solar Module Production Lines – Complete Guide (15–1200 MW)

Establishing a solar module production line is a significant capital investment. For investors, energy project developers, and established manufacturers, the central challenge isn’t just acquiring machinery—it’s designing a complete, reliable system that delivers a strong return. The capacity of your plant, whether an entry-level 15 MW line or a 1200 MW gigafactory, directly influences capital expenditure (CAPEX), operational costs (OPEX), and your market position.

This guide is designed to give you the clarity needed to evaluate your options. We will walk you through a direct comparison of production capacities, explain what’s included in a turnkey solution, and outline the services that ensure your factory is successful from day one.

Our goal is to equip you with the essential data to make a confident, well-informed decision. You aren’t just buying equipment; you’re building a foundation for long-term energy production.

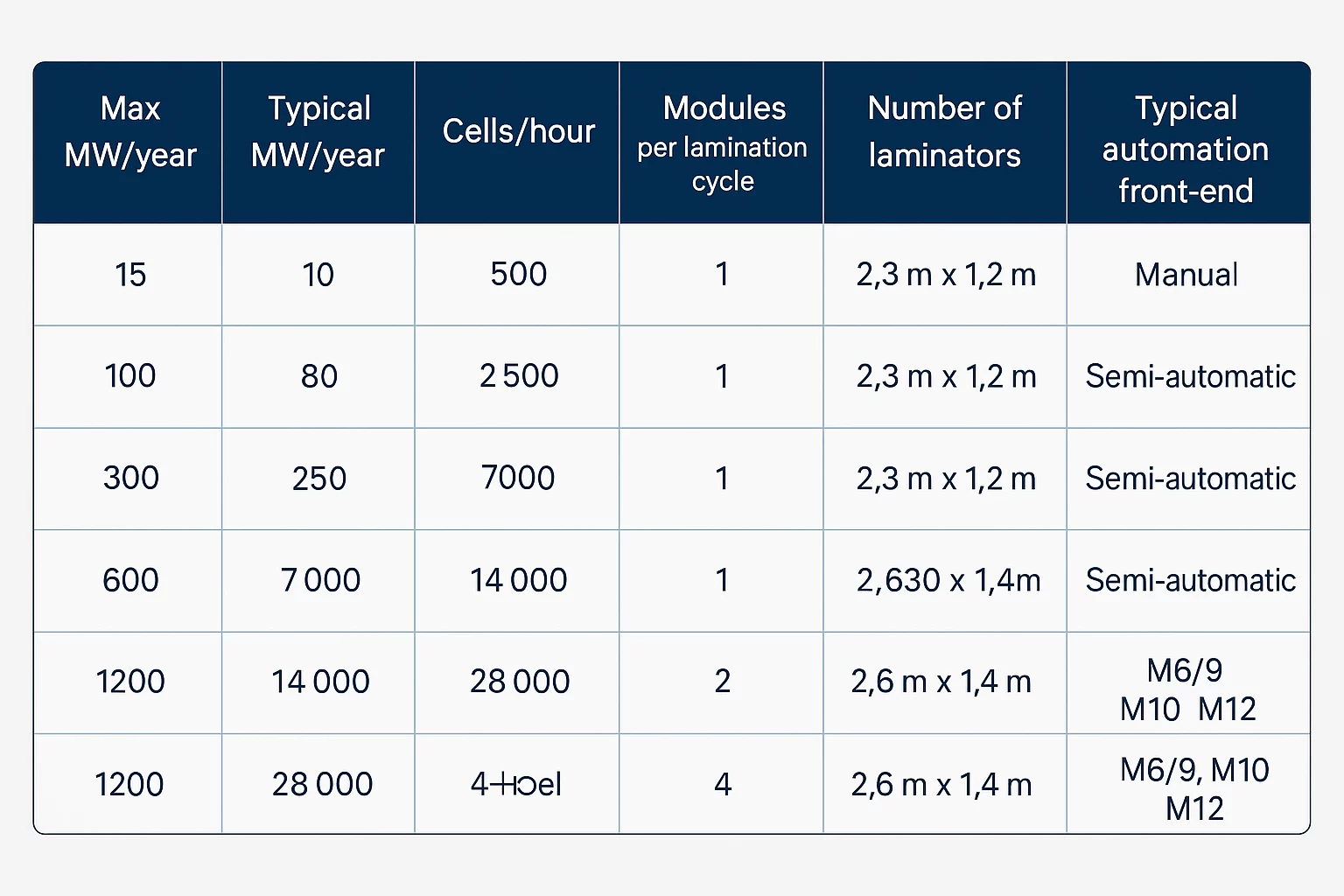

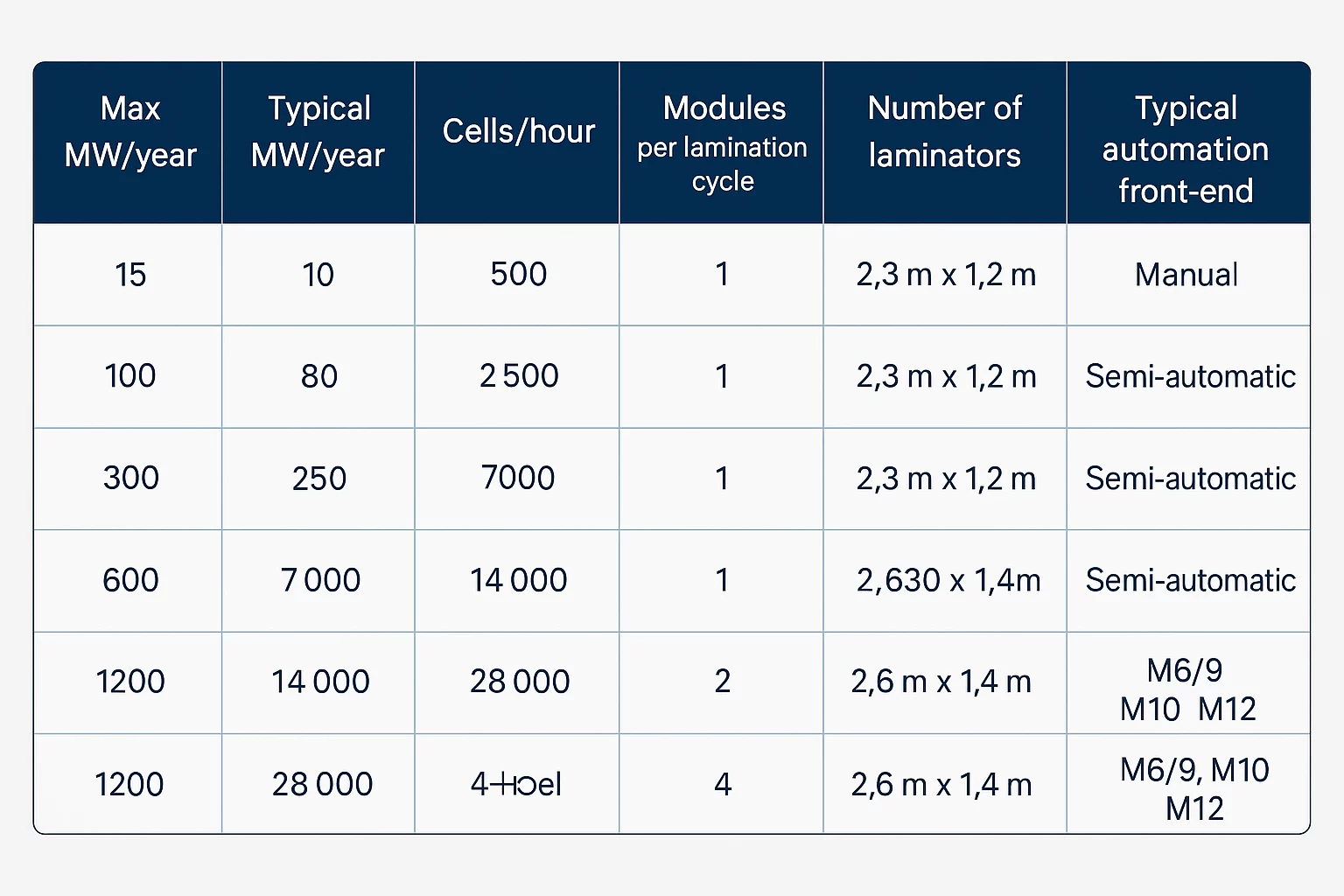

Production Line Capacity Comparison: 15 MW to 1200 MW

An effective comparison requires transparent data. Unlike other providers who require an inquiry to see basic specifications, we believe in providing a clear overview upfront. This data helps translate abstract capacity numbers into tangible outputs and required automation levels. Key performance indicators for our production lines include:

- 15 MW Refurbished: An entry-level line with manual layup, typically producing 12 MW per year. It processes 500 cells per hour and is ideal for small-scale projects using M2–M6 cells.

- 25 MW to 50 MW: These semi-automatic lines process 1,800 cells per hour and are compatible with modern M2–M12 cells. They are a popular choice for new businesses and regional distributors.

- 100 MW to 200 MW: Marking the entry into higher automation, these lines feature automatic layup and bussing, processing up to 7,200 cells per hour. They support advanced cell types like TOPCon and HJT.

- 300 MW to 800 MW: These fully automatic lines are designed for industrial-scale production. They feature advanced MES and can process up to 28,800 cells per hour for a typical annual output of 650 MW.

- 1200 MW: Our gigafactory solution is a fully automated system with integrated logistics, processing 43,200 cells per hour. It supports next-gen cell technologies, including Tandem, for maximum market competitiveness.

All specifications are based on our standard offer data and can be customized to meet your project’s specific requirements.

What Is Included in a J.v.G. Turnkey Production Line?

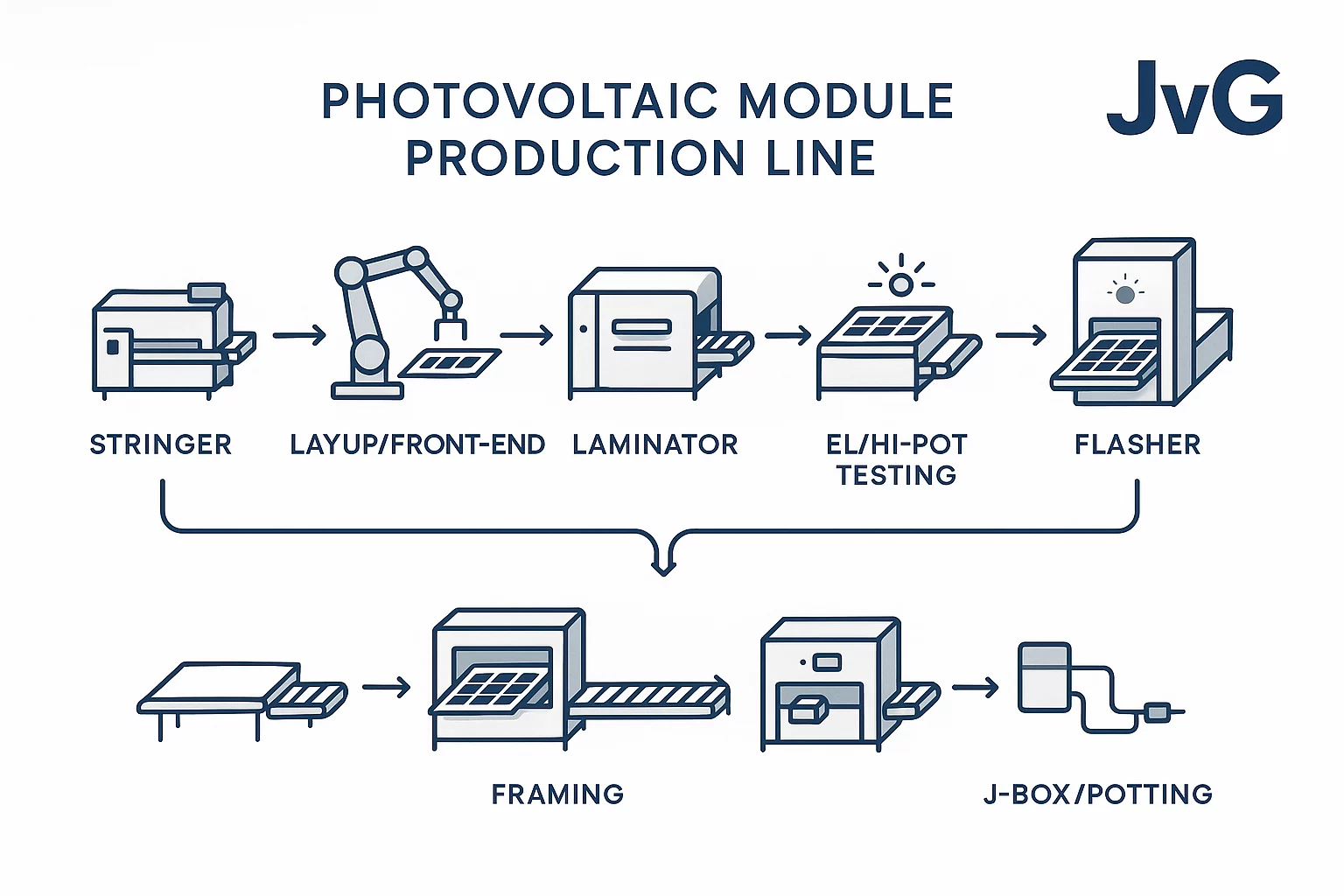

A high-performance solar module factory is more than a collection of machines; it’s a fully integrated system engineered for reliability and efficiency. Our turnkey solutions provide all the core equipment needed to transform raw materials into certified, market-ready solar panels. Each component is selected and configured to work seamlessly with the others, ensuring quality control and operational stability.

Core Equipment in Every J.v.G. Line:

- Cell Stringer: Automatically solders solar cells into strings with precision.

- Layup and Front-End Station: Assembles the panel layers (glass, EVA, cell matrix, backsheet) before lamination. Automation levels vary by line capacity.

- Laminator: The heart of the production line, using heat and vacuum to encapsulate the panel. The number of laminators scales directly with capacity.

- EL and Hi-Pot Tester: Inspects for micro-cracks and ensures electrical insulation and safety.

- Sun Simulator (Flasher): Measures the electrical performance of the finished module to classify its power output.

- Framing Machine: Automatically attaches the aluminum frame to the module.

- J-Box and Potting Station: Secures the junction box and applies potting compound for weather protection.

Automation and material handling systems are integrated based on your chosen capacity to minimize manual intervention, reduce errors, and maximize throughput.

Services, Delivery, and Commercial Terms

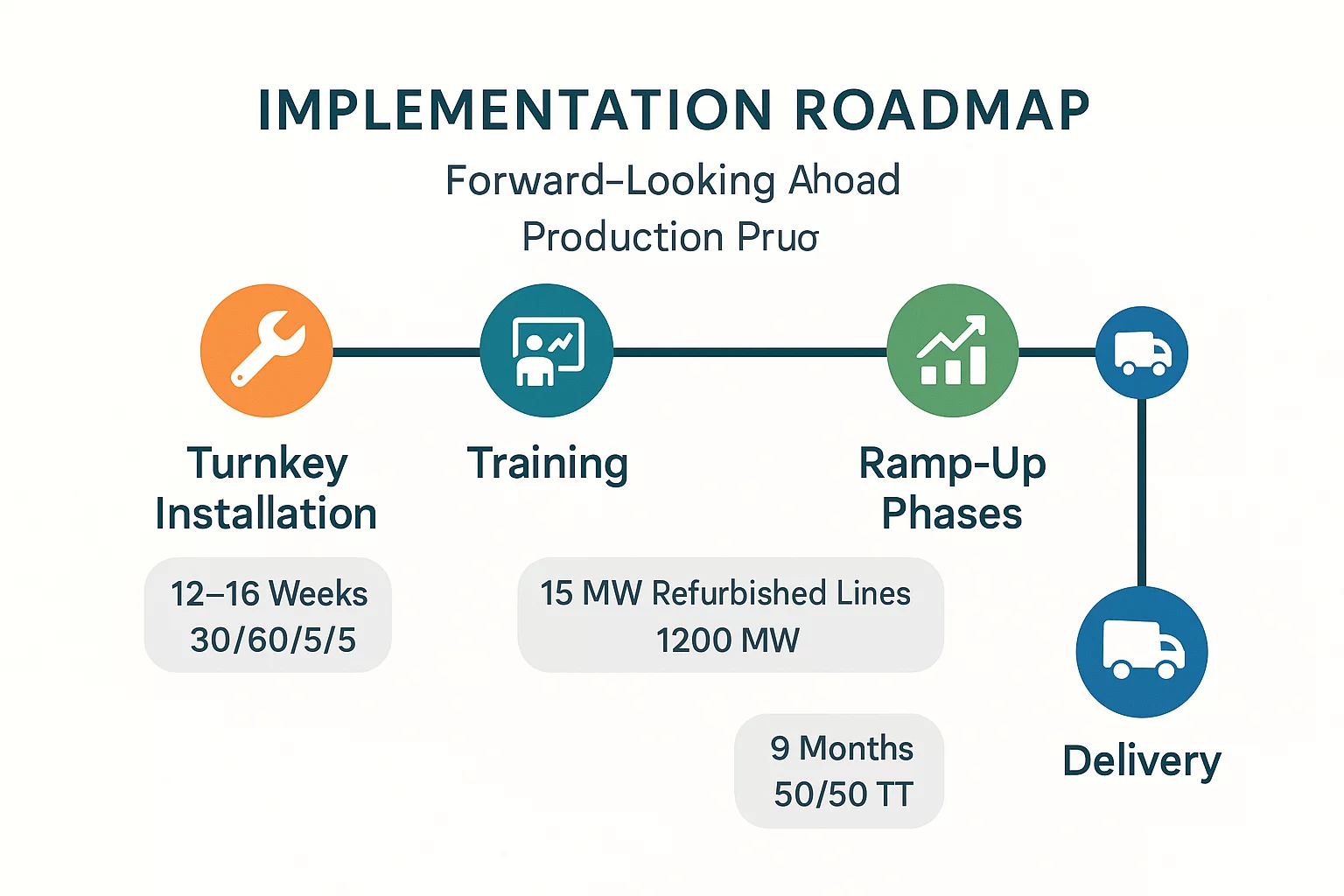

Your success depends on a smooth transition from contract to full-scale production. We manage this entire journey with a structured, transparent process built on over 25 years of global experience. Our commitment extends far beyond equipment delivery.

Our Turnkey Service Includes:

- Installation and Commissioning: Our engineers oversee the complete on-site installation of your solar panel manufacturing plant, ensuring every machine is calibrated for peak performance.

- Operator Training: We provide comprehensive training for your local staff, covering operations, quality control, and routine maintenance.

- Production Ramp-Up Support: We remain on-site after commissioning to guide your team as you ramp up to full production capacity, helping resolve challenges in real time.

- Compliance and Certification: All our equipment is engineered to meet international standards (e.g., TÜV, IEC), simplifying your path to final module certification.

Typical Delivery and Payment:

- Delivery Timeline: Standard new lines are typically delivered within 6–9 months, with our 1200 MW lines requiring a 9-month timeline. Our 15 MW refurbished lines are available in 12–16 weeks.

- Payment Terms (New Lines): 30% down payment, 60% upon delivery, 5% after commissioning, and 5% after final acceptance.

- Payment Terms (Refurbished Lines): 50% down payment, 50% upon delivery (payable by Telegraphic Transfer).

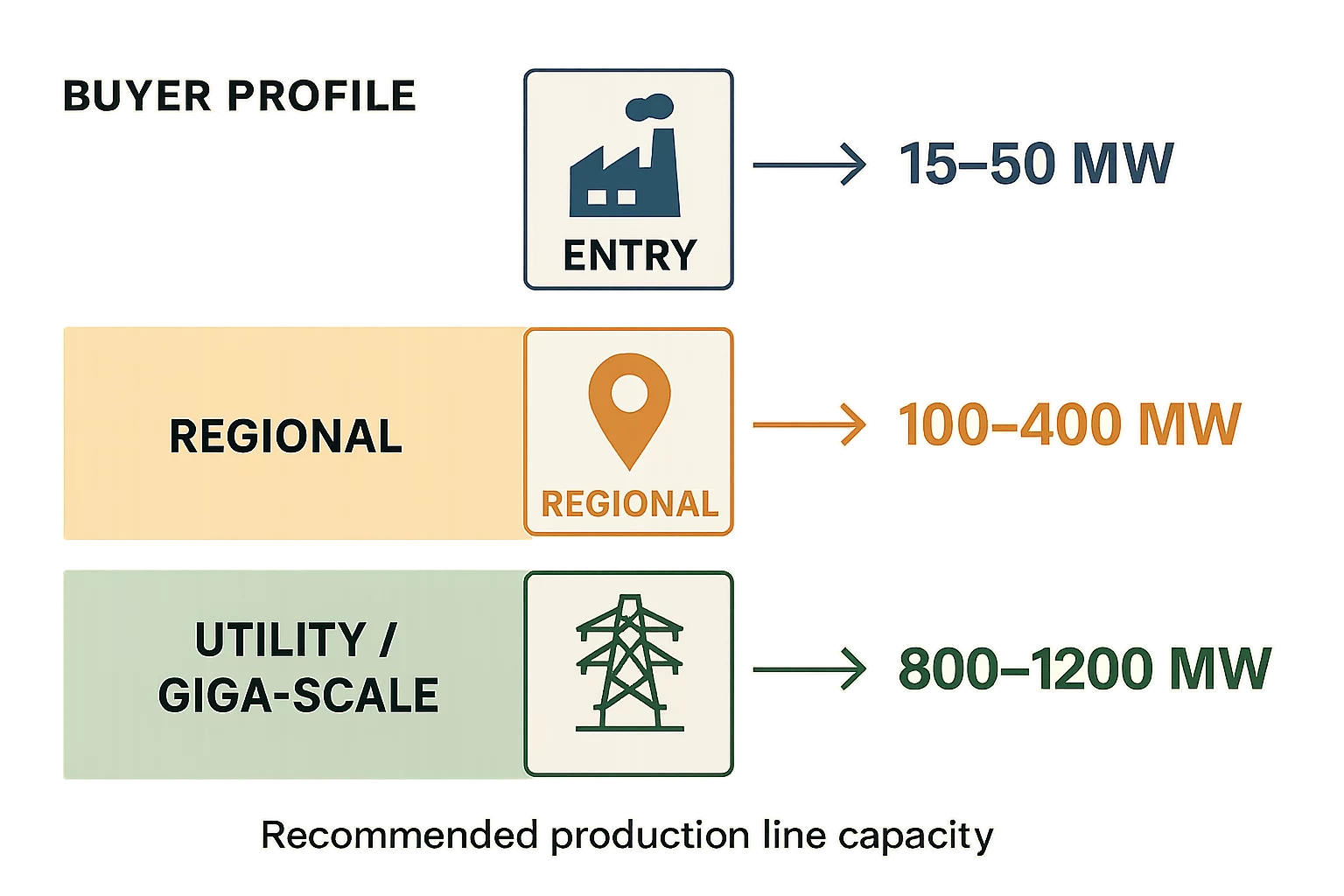

How to Select the Right Capacity for Your Project

Choosing the right production capacity is a strategic decision that should align with your business objectives, market size, and long-term vision. We have designed our range of production lines to meet the needs of distinct investor profiles, each with a clear path for future growth.

Entry-Level Production (15 MW – 50 MW)

- Ideal for: New entrepreneurs entering the solar market, smaller regional distributors aiming for vertical integration, or government-backed pilot projects.

- Strategy: These lines offer the lowest capital investment and a faster path to market. They are perfect for serving niche markets or satisfying local content requirements without the complexity of a large-scale operation.

Regional and Commercial Scale (100 MW – 400 MW)

- Ideal for: Established businesses, EPC contractors, and investors looking to become a significant supplier for residential, commercial, and small utility projects in their region.

- Strategy: These lines balance high throughput with a manageable operational scale. The increased automation delivers excellent efficiency and product consistency, allowing you to compete effectively on both quality and price.

Utility and Gigawatt Scale (800 MW – 1200 MW)

- Ideal for: Large corporations, national energy providers, and institutional investors aiming to supply major utility-scale solar farms and compete in the global market.

- Strategy: Built for maximum output and efficiency, these gigafactories leverage full automation and advanced production management systems to achieve the lowest cost per watt. They are designed for 24/7 operation and economies of scale.

All our production lines are designed with the future in mind, offering clear, cost-effective upgrade paths to expand your capacity as your market share grows.

Explore Our Production Lines in Detail

For a deeper look into the specifications, layouts, and investment profiles of each capacity, please see our detailed guides.

25 MW Solar Module Production Line

The ideal entry point for serious entrepreneurs, this semi-automated line offers a strong balance of investment and output for regional markets. Learn more about the 25 MW PV module production equipment.

50 MW Solar Module Production Line

Double your output on the same footprint as the 25 MW line using a more efficient laminator. This is a popular choice for growing businesses. Discover the 50 MW solar manufacturing machines.

100 MW Solar Module Production Line

Marking the entry into fully automated production, the 100 MW line is a competitive solution for serving both residential and commercial solar demand. See the full 100 MW photovoltaic panel production line.

200 MW Solar Module Production Line

A powerful option for established manufacturers, this line offers significant scale and efficiency for capturing substantial regional market share. Explore the 200 MW solar panel factory setup.

400 MW Solar Module Production Line

This highly automated line is engineered for serious industrial producers targeting large-scale projects and distribution networks. Review the 400 MW solar module factory investment details.

1200 MW Solar Module Production Line

Our gigawatt-scale solution is built for market leaders. This fully automated factory is designed for maximum throughput and integration with global supply chains. Inquire about the 1200 MW PV manufacturing plant.

Frequently Asked Questions

What is the estimated total investment for a turnkey solar module factory?

The total investment depends heavily on the chosen capacity, level of automation, and local factors like land and building costs, though the machinery itself is the primary driver of CAPEX. While the typical payback period is 4–7 years, a detailed offer will provide a precise breakdown for your business case.

What is the required factory footprint and building height?

A 25 MW line typically requires around 1,500 square meters, while a 100 MW line needs approximately 3,000–4,000 square meters. Gigawatt-scale factories require significantly more space for production, warehousing, and logistics. A minimum ceiling height of 6 meters is generally recommended.

How many people are needed to operate the production line?

Staffing needs depend directly on the line’s level of automation. A semi-automated 25 MW line might require 20–25 operators per shift, whereas a fully automated 400 MW line may only need 15–20 operators per shift due to robotic handling and integrated processes.

What are the main energy and utility requirements?

The primary utilities are electricity and compressed air, and the laminator is the largest single consumer of electricity. Total power requirements scale with capacity, from approximately 150 kW for a small line to several megawatts for a gigafactory.

Can a smaller production line be upgraded to a higher capacity later?

Yes. We design our lines with scalability in mind. The most common upgrade path is adding more stringers and laminators to resolve production bottlenecks and increase total annual output. This allows your initial investment to grow with your business.

What kind of warranty and after-sales support do you provide?

All our new equipment comes with a full parts and service warranty. More importantly, we offer long-term support and a dedicated point of contact within our family-run company. You get direct access to the engineers who designed your line, ensuring fast and effective solutions.

What does the operator training program include?

Our on-site training covers everything your team needs to know: machine operation, process control, quality checks using the EL tester and sun simulator, standard maintenance procedures, and safety protocols. We ensure your team is confident and self-sufficient before we complete our handover.

Plan Your Solar Manufacturing Project with an Experienced Partner

For over 25 years, J.v.G. technology has helped entrepreneurs and investors across the globe build successful solar module factories. We understand the operational challenges, from supply chain planning to securing skilled labor. You bring the vision and the investment—we provide the engineering, technology, and hands-on support to make it a reality.

If you are ready to discuss the specific requirements for your project, we invite you to reach out. We’d be happy to provide a detailed, no-obligation offer tailored to your goals.