Tailored Technology:

Not One-Size-Fits-All

A solar module factory is more than a collection of machines; it’s a strategic asset that must perform reliably in your specific environment for decades. While many suppliers offer standard, pre-configured production lines, that approach fails to address the critical variables that determine your long-term success.

Your vision, your market, and your local conditions demand a solution engineered specifically for you.

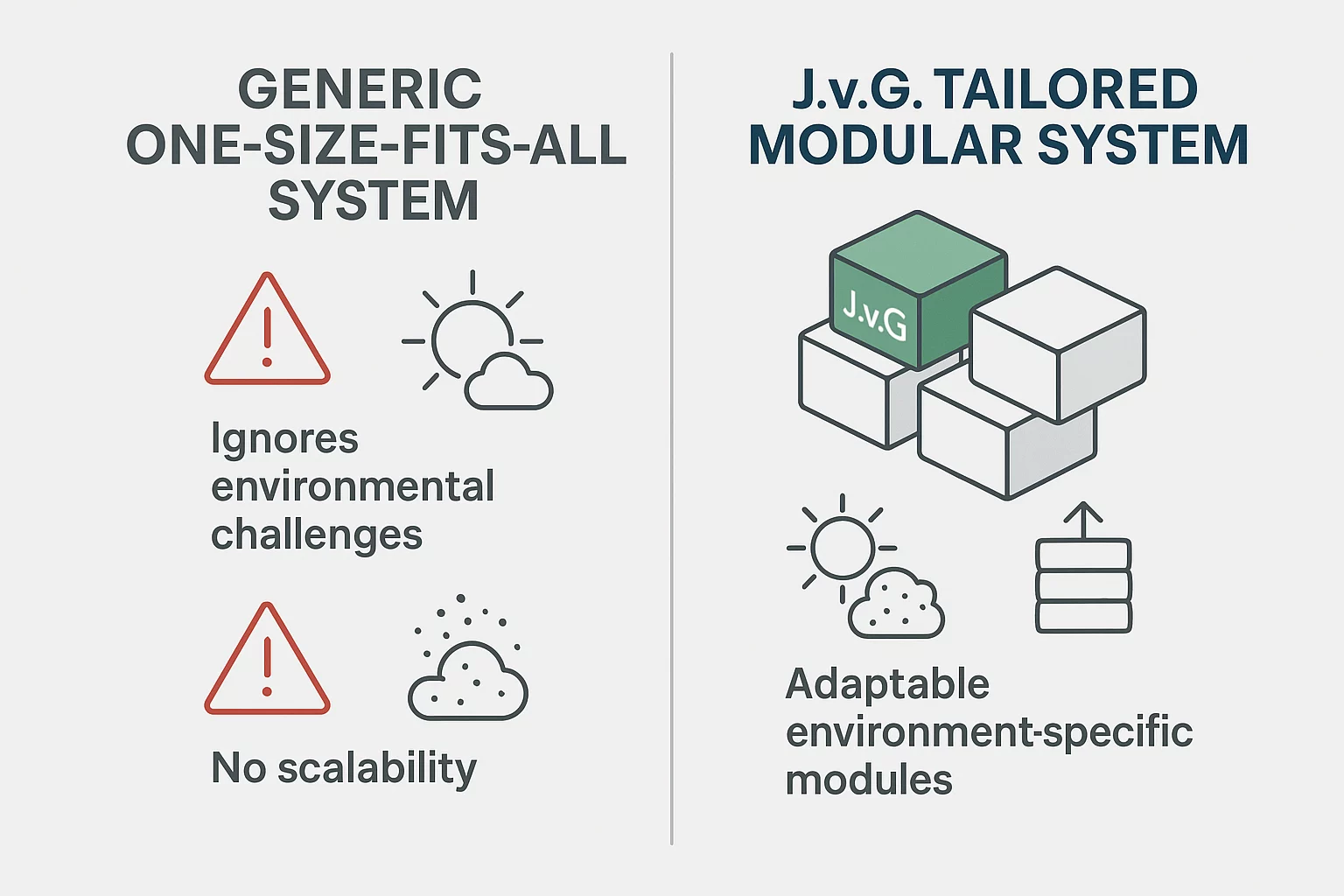

The Flaw of the “One-Size-Fits-All” Factory

Standardized production lines are designed for an ideal, generic environment that rarely exists in the real world. They overlook critical factors like extreme heat, dust, humidity, or complex local logistics.

This oversight introduces significant risk: a system not built for its surroundings will inevitably suffer from lower output, higher maintenance costs, and a diminished return on investment. A factory should be an asset, not a liability.

Our Philosophy: Modular, Adaptable, and Resilient

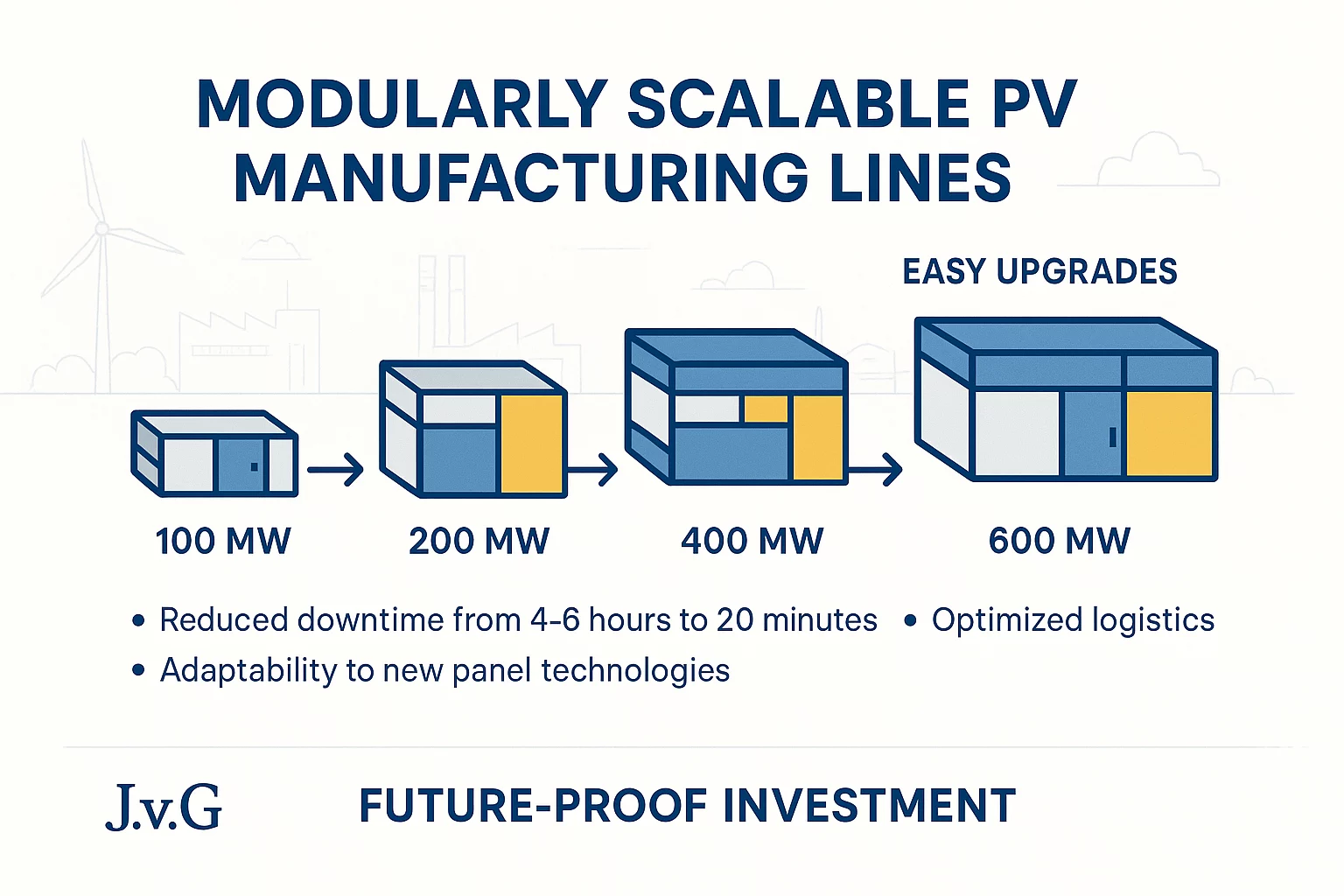

We build your production line on a modular philosophy. This allows us to configure a system that precisely matches your business goals, budget, and facility layout. More importantly, it gives you the agility to adapt over time.

If a single component needs servicing, a module can be swapped in as little as 20 minutes—a stark contrast to the 4-6 hours of downtime common with integrated systems. This resilience is fundamental to maintaining profitability.

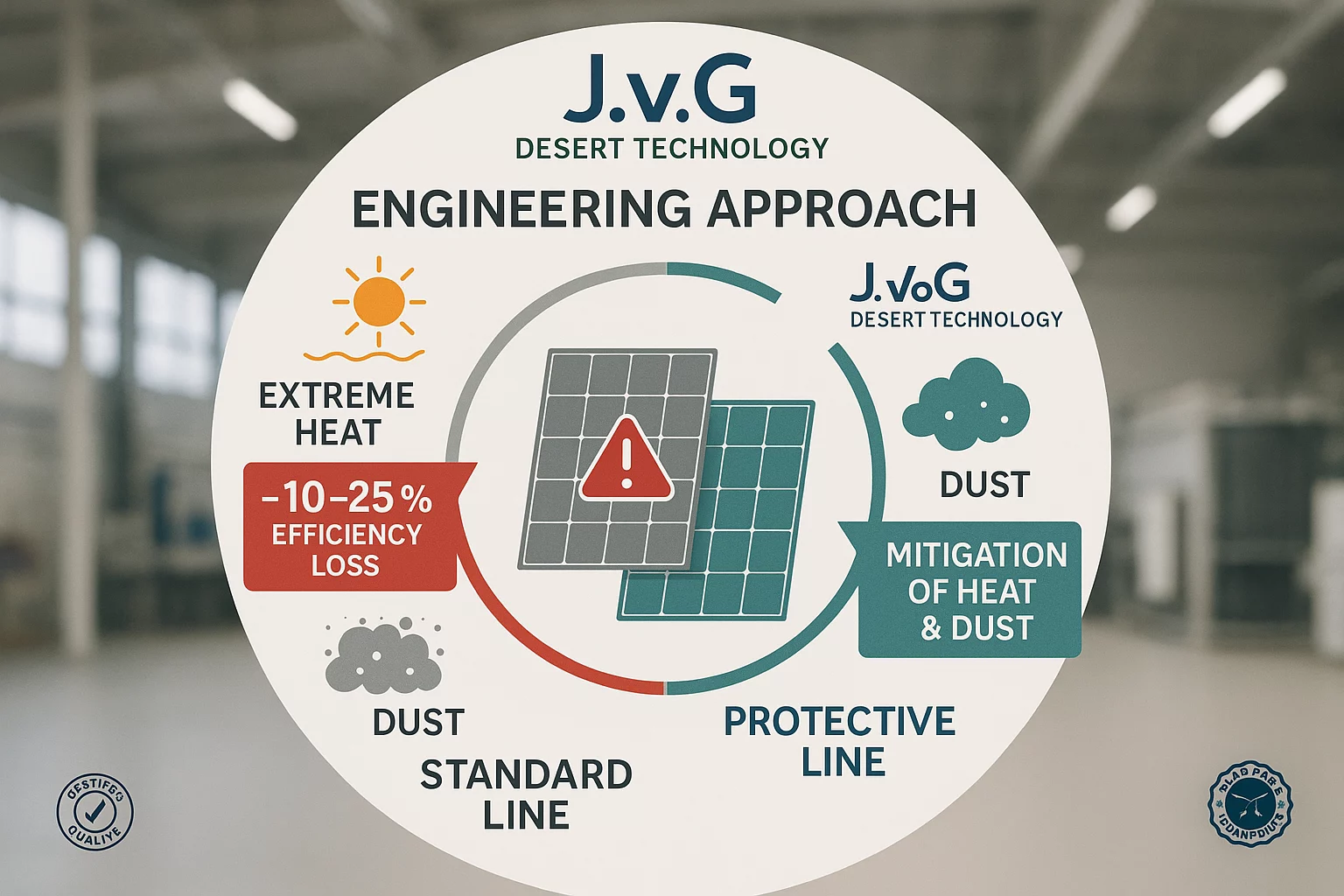

Engineered for Extremes: The Desert Technology Advantage

Operating in challenging climates demands specialized engineering. Research shows that standard solar manufacturing can see output drop by up to 30% from dust accumulation and by 10-25% in the extreme heat of desert regions.

Our proprietary DESERT Technology directly counters these threats with enhanced sealing, advanced cooling systems, and robust components built to protect your production. This is not an add-on; it’s a core design principle that safeguards your investment.

A Scalable System Designed for Your Growth

Your investment today should serve your ambitions for tomorrow. A modular J.v.G. production line is inherently scalable, letting you begin with a capacity that matches your current market demand and expand it incrementally as your business grows.

This approach also future-proofs your factory by allowing you to easily integrate new module sizes or cell technologies as the industry evolves, ensuring you remain competitive for years to come.

Your Vision Requires a Strategic Partner

If your vision requires more than off-the-shelf equipment, it requires a strategic partner. Building a successful factory means working with an expert who understands how to translate your goals into a robust, site-specific technical solution. For over 25 years, we have guided entrepreneurs and investors across the globe through this process.

Let’s talk about what’s possible in your region.