Phase 3:

Technical Design & Line Configuration

When evaluating partners for your solar manufacturing project, you have likely encountered providers offering ‘turnkey solutions.’ Yet, this term often raises more questions than it answers. Is the solution truly designed for you? Is it tailored to your specific market, budget, and long-term vision?

A list of machines is not a strategy. True partnership begins with a collaborative design process grounded in deep technical expertise.

This is where the real work begins: transforming your business goals into a detailed, operational blueprint. This phase is not about selecting equipment from a catalog; it is about engineering a production line that gives you a sustainable competitive advantage. That requires a partner who listens first, then designs a solution that is efficient, scalable, and precisely aligned with your objectives.

Beyond Turnkey: A Collaborative Approach to Technical Design

While many providers focus on their equipment, we focus on your project’s success. We believe the most critical phase is the technical design, where vision meets engineering.

Our process is built on collaboration and transparency, ensuring you have complete confidence in every decision. We guide you through the complexities of technology selection, layout, and automation to create a factory built for today’s demands and ready for tomorrow’s growth.

Our proven, five-step process ensures every technical detail is aligned with your strategic goals.

Our 5-Step Technical Design Process

Needs Assessment & Goal Alignment

Before we discuss any equipment, we first work to understand your vision. We analyze your target market, financial models, and long-term ambitions. Are you aiming for a specific regional market? What are your production volume targets for year one, year three, and year five? This foundational step de-risks your investment by ensuring the final engineering plan is built to achieve your specific business outcomes.

Equipment Selection & Technology Integration

With a clear understanding of your goals, we move to equipment selection. This is a consultative process, not a sales pitch. We help you navigate the trade-offs between different technologies, considering factors like material compatibility, maintenance requirements, and integration with quality control systems.

We also focus on critical, often-overlooked details like cleanroom standards and automated material handling. These elements are essential for maximizing module efficiency and production yield.

Layout Planning & Workflow Optimization

The physical layout of your factory determines its efficiency. We design the floor plan to optimize material flow, minimize handling, and create a safe, productive work environment. Our detailed 2D and 3D plans allow you to visualize the entire production process—from raw material intake to final module packaging—ensuring every square meter of your facility is used effectively.

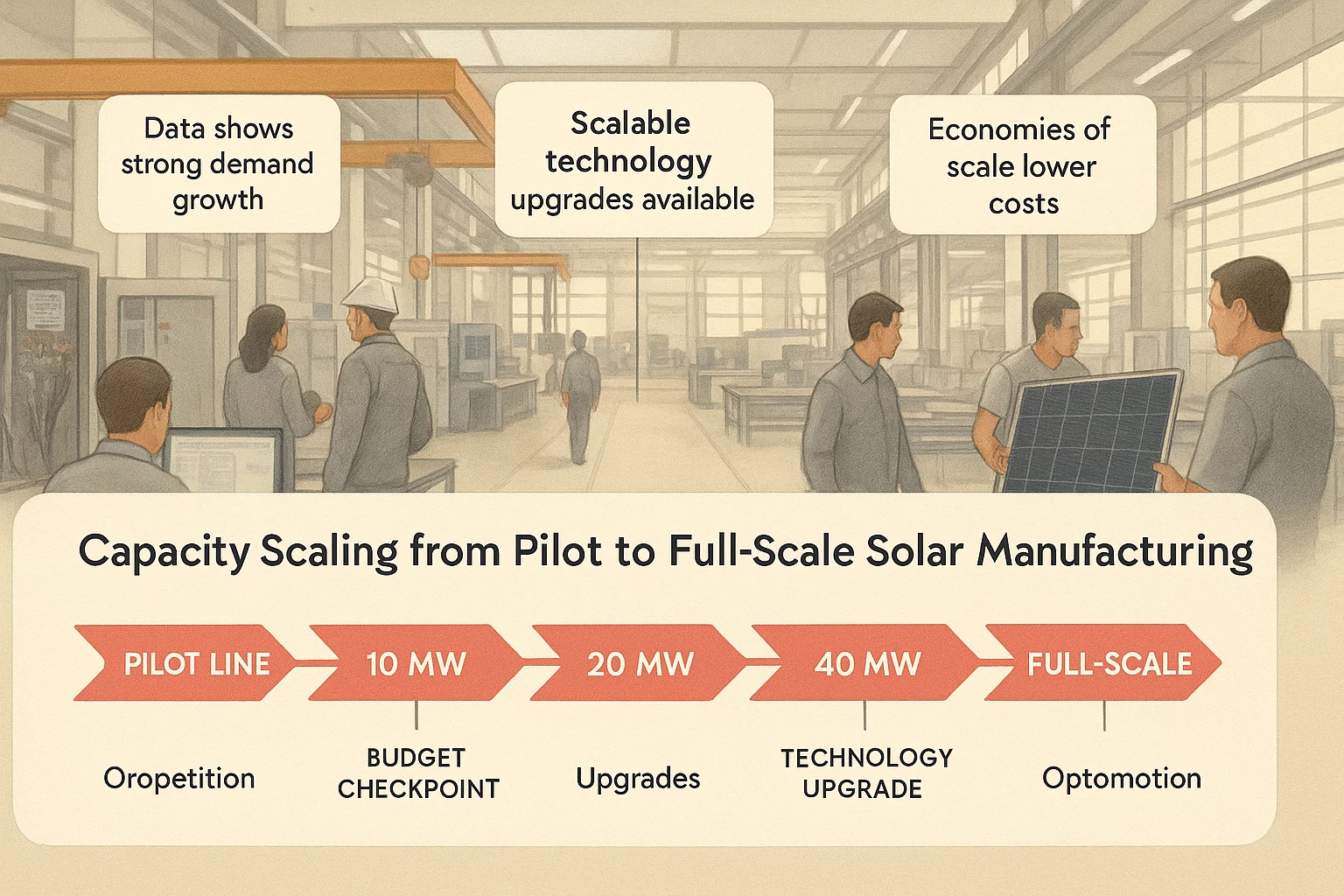

Capacity Scaling & Future-Proofing

Your initial production capacity is just the beginning. In a market experiencing rapid growth, scalability is not an option—it is a necessity. We design your line with the future in mind, creating a clear roadmap for expansion. This approach allows you to scale production capacity in predictable phases without a complete facility redesign.

Automation & Robotics Integration

Deciding on the right level of automation is one of the most important technical decisions you will make. While it can seem complex, the choice should be driven by a clear cost-benefit analysis. With labor accounting for less than 10% of module production costs in advanced markets, the primary driver for automation is often quality, consistency, and yield—not just labor savings. We help you identify the precise points in the production process where automation will deliver the highest return on investment.

Frequently Asked Questions

The ideal level of automation depends on your specific goals, labor market, and production volume. For many projects, a semi-automated line is a highly effective starting point, with options to integrate more robotics later. We help you analyze the trade-offs to find the right balance between initial investment and long-term operational efficiency.

That is precisely why we act as your dedicated partner. You bring the business vision and investment; we provide decades of hands-on engineering experience. Our role is to translate your goals into a fully operational factory and guide you at every step, ensuring you feel confident and informed throughout the process.

Absolutely. We design every line with future-proofing in mind. From the initial layout to the selection of modular equipment, we ensure your factory can grow with your business and adopt new technologies without costly disruptions.

Our global experience, particularly in emerging markets, has taught us there is no one-size-fits-all solution. We consider local factors such as climate, supply chain logistics, labor skills, and regulatory requirements during the design phase. This ensures your factory is not just technically sound but also perfectly suited to its operating environment.

Let’s Build Your Factory’s Blueprint Together

A successful solar manufacturing venture is built on a foundation of expert technical design. It requires a partner who understands that you are not just buying machines—you are building a sustainable business.

We are ready to translate your vision into a detailed, operational plan.

Contact our experts today to start designing your custom solar production line.