From Construction to Full Capacity: Your Partner in Solar Production Ramp-Up

Completing the construction of your solar module factory is a major milestone, but it’s only the beginning. The most critical phase for your long-term success starts now: the period of commissioning, training, and production ramp-up. This complex process is where your investment truly transforms into a productive, profitable asset.

Many investors find this phase daunting. Technical guides often lack a business perspective, and it’s common for partners to disappear after the initial setup. A poorly managed ramp-up creates significant risks, leading to costly delays, underperforming assets, and a frustrated local team.

At J.v.G., we understand that you aren’t just buying equipment; you’re building a business. Our role extends far beyond engineering. We remain by your side to ensure a smooth, efficient transition from a new facility to a fully operational production line.

The J.v.G. Partnership Model: A Step-by-Step Guide

Our approach is designed to eliminate uncertainty and build lasting capability. We’ve refined a comprehensive process that covers every detail, from the initial power-on to full-scale production. Our commitment is simple: we stay until your team is confident and your line is performing at its highest potential.

Commissioning & Technical Acceptance

Before the first module is produced, we conduct a meticulous verification of the entire line. This includes both “cold” commissioning (power off) and “hot” commissioning (power on) to ensure every component functions perfectly.

Ramp-Up & Process Fine-Tuning

With the system fully commissioned, we supervise the initial production runs. This isn’t just a test; it’s the beginning of active production under our expert guidance.

Local Team Training & Knowledge Transfer

Our most important task is to empower your local team. We believe in building self-sufficiency, not dependency.

Performance Verification & Official Handover

We define success with clear, measurable targets. The project isn’t complete until your factory meets the performance metrics we agreed upon.

Our Commitment: The ‘No Handoff-and-Run’ Guarantee

The single greatest fear for an investor new to the solar industry is being left alone to manage a complex factory. This is a valid concern, and it’s why we built our company on a different philosophy.

The “no handoff-and-run” guarantee is our promise to you. As a family-owned business, our reputation is built on the long-term success of our clients. We consider you a partner, and our support continues long after the formal handover is complete. We remain available for consultation, troubleshooting, and guidance as your business grows. You aren’t just buying a factory; you’re gaining a dedicated engineering partner for the life of your facility.

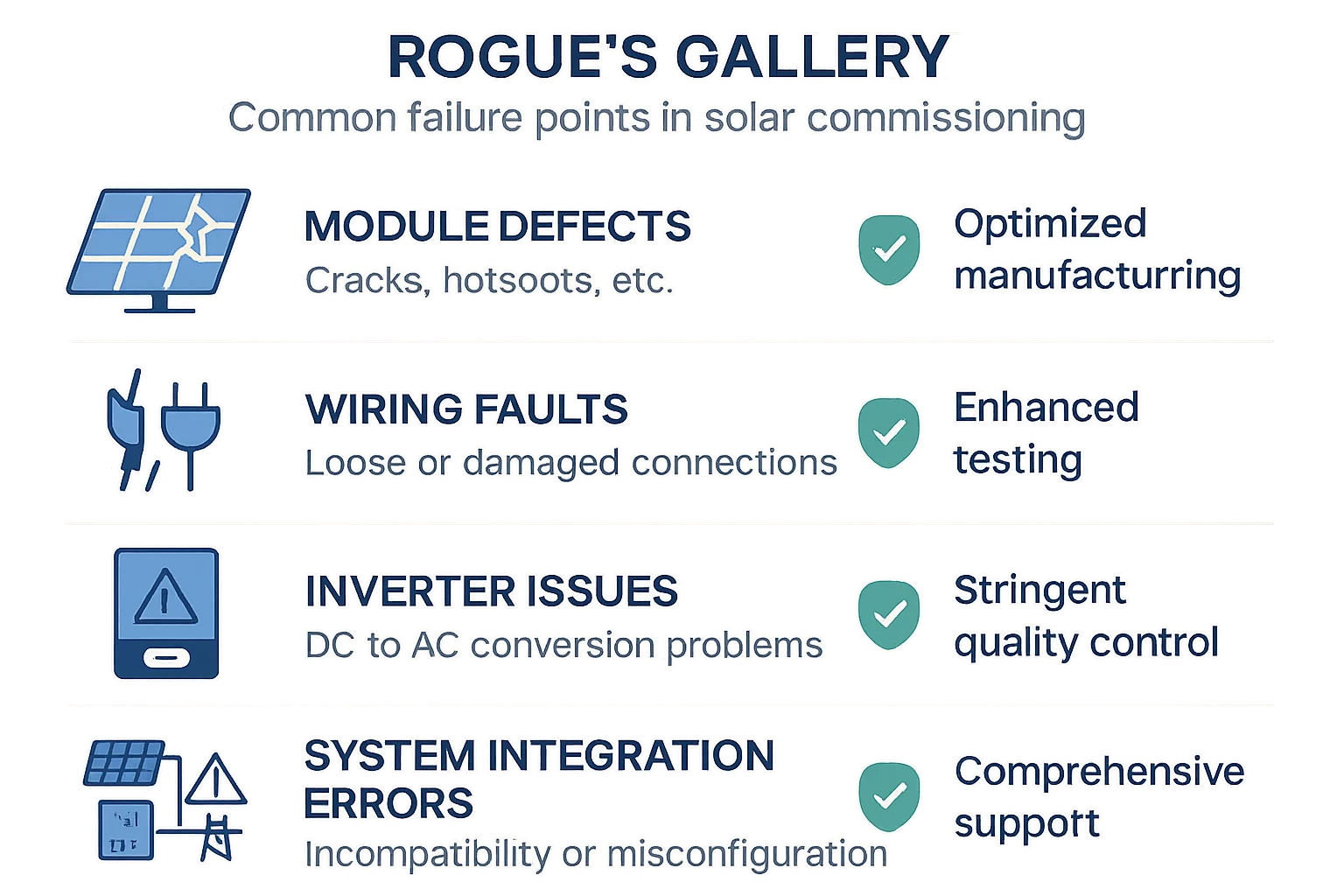

De-Risking Your Investment: Common Pitfalls and How We Avoid Them

Decades of experience have taught us where projects are most likely to fail. Our commissioning process is specifically designed to mitigate these risks before they can impact your operations and profitability. As research from the IEA highlights, these failure points often arise from seemingly small details that have major consequences.

The Pitfall: Module defects like delamination or micro-cracks caused by incorrect machine calibration.

Our Solution: We fine-tune every parameter during the ramp-up phase, using our proprietary process knowledge to ensure high-quality, durable modules from the very first batch.

The Pitfall: System integration errors where machines from different suppliers do not communicate effectively, causing bottlenecks.

Our Solution: As a turnkey provider, we supply a fully integrated line where all components are designed to work together. Our commissioning process verifies this seamless integration, eliminating communication conflicts.

The Pitfall: Inverter issues or wiring faults that create safety hazards and cause significant downtime.

Our Solution: Our rigorous safety audits and electrical commissioning tests identify and correct these issues long before the factory goes into full operation, ensuring both safety and reliability.

Frequently Asked Questions

The timeline varies with the project’s scale and the local team’s initial experience. However, a typical process from commissioning to stable handover takes between four and eight weeks. Our focus is on being thorough, not fast.

No. Our training program is designed for intelligent, capable individuals who may not have specific solar industry experience. We teach everything from basic operations to advanced maintenance, empowering your local hires to become proficient technicians.

Our partnership does not end at handover. You will have direct access to our support team for troubleshooting and guidance. We are committed to your long-term success and remain available to help you navigate any challenges that arise as you grow.

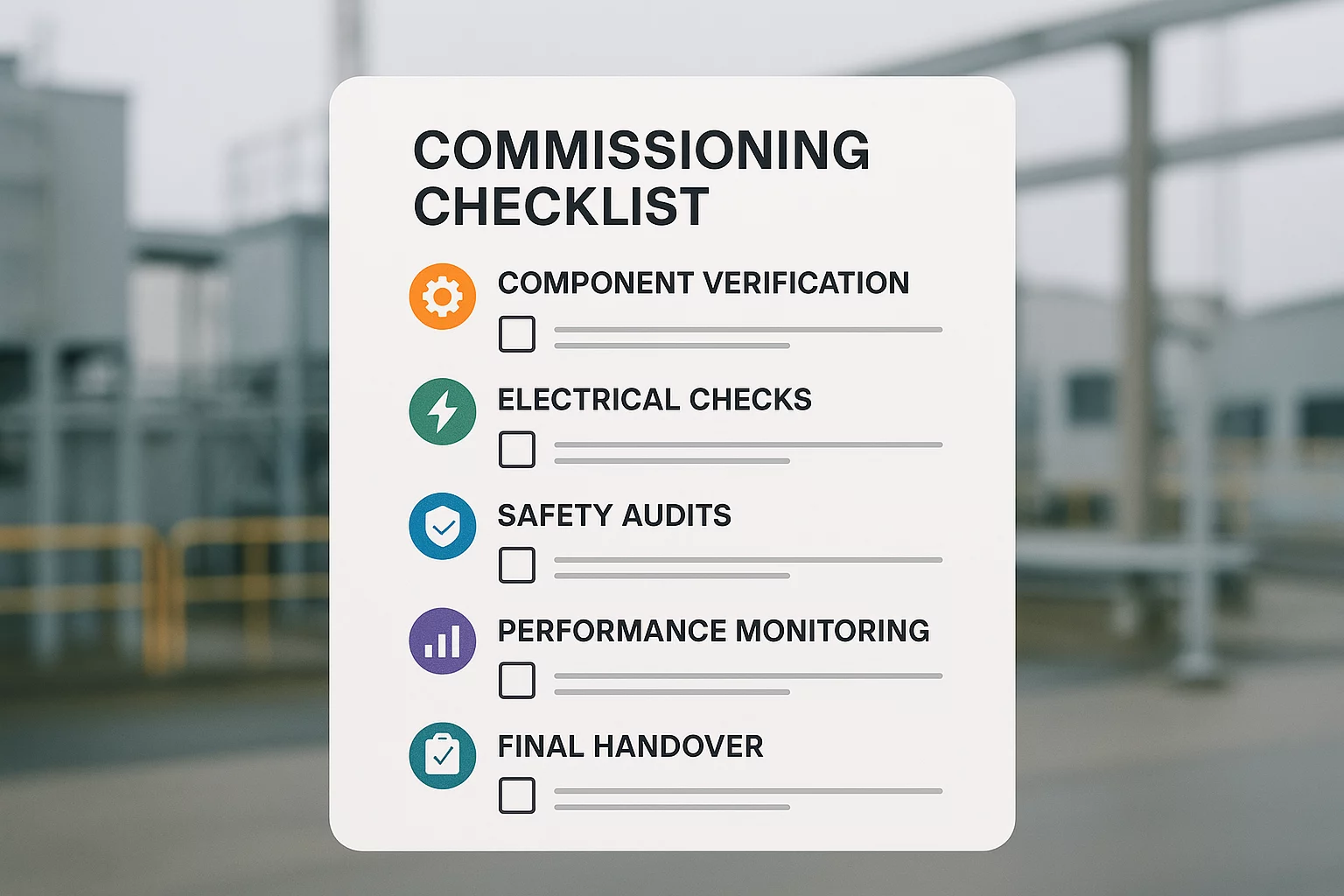

Your Guide to a Successful Launch

To help you better understand the critical steps involved, we have prepared a comprehensive checklist outlining the key stages of a successful commissioning and ramp-up process. This checklist provides a clear roadmap from a new facility to a high-performing asset.

Navigating the critical phase of bringing a solar factory online requires a partner as invested in your success as you are. You bring the vision and the investment; we bring the technical expertise and unwavering support to make it a reality.

We are ready to discuss your project.