The initial draft of your business plan sits on your desk. The numbers are promising: projected revenues, production costs, and profit margins all point toward a successful venture. Yet, for any serious investor in solar module manufacturing, a persistent question remains: How reliable are these figures in a market that can change overnight?

A financial model based on today’s prices is merely a snapshot in time. A resilient business plan must be a dynamic tool—one that anticipates change. The single greatest variable you will face is the fluctuating cost of raw materials. Understanding how to model this volatility isn’t just a financial exercise; it’s the foundation of a sustainable and profitable operation.

The Core Challenge: Fixed Projections vs. a Dynamic Market

In solar module manufacturing, a significant portion of your Operating Expenditures (OpEx) is variable, tied directly to the price of a few key raw materials. While you can forecast fixed costs like rent and salaries with reasonable accuracy, material costs hinge on global supply and demand, geopolitical events, and shifts in energy prices.

Industry analysis from 2020-2023 shows how dramatic these shifts can be. Polysilicon prices, for example, fluctuated by over 300% within that period. Solar glass and EVA films, while less volatile, still saw price swings of 30-50%, directly impacting the final cost per module. Ignoring this reality in your business plan is like setting sail without checking the weather.

Understanding the ‘Big Three’ Cost Drivers in Solar Module Production

Building a realistic financial model starts with understanding the primary materials that drive your costs. While a solar module contains many components, three materials typically represent the largest share of the bill of materials (BOM).

Polysilicon: The Foundation of Your Solar Cells

This high-purity silicon is used to produce solar cells, the engine of your module. Its price is heavily influenced by global production capacity—concentrated in a few key regions—and the high energy costs required for its refinement. A spike in energy prices or a disruption in a major production zone can cause polysilicon costs to rise sharply, directly affecting your most critical component.

Solar Glass: Your Module’s First Line of Defense

The specially tempered, low-iron glass that protects solar cells from the elements is another significant cost. Its production is also energy-intensive, requiring large furnaces to run continuously. As a result, its price is sensitive to regional energy costs and the availability of raw materials like soda ash and silica sand.

EVA Film: The Laminate That Binds It All

Ethylene Vinyl Acetate (EVA) is the polymer used to encapsulate solar cells, protecting them from moisture and ensuring long-term performance and durability. As a petroleum-based product, its price is linked to the broader petrochemical market. Fluctuations in crude oil prices can and do affect the cost of this essential laminating material.

From Static Numbers to a Dynamic Model: Introducing Sensitivity Analysis

The most effective tool for managing this uncertainty is sensitivity analysis, a method for testing how your project’s bottom line reacts to changes in key assumptions. It allows you to answer critical ‘what if’ questions:

-

What happens to my profitability if polysilicon prices increase by 20%?

-

At what price point for solar glass does my project become unprofitable?

-

How does a 15% drop in material costs impact my return on investment?

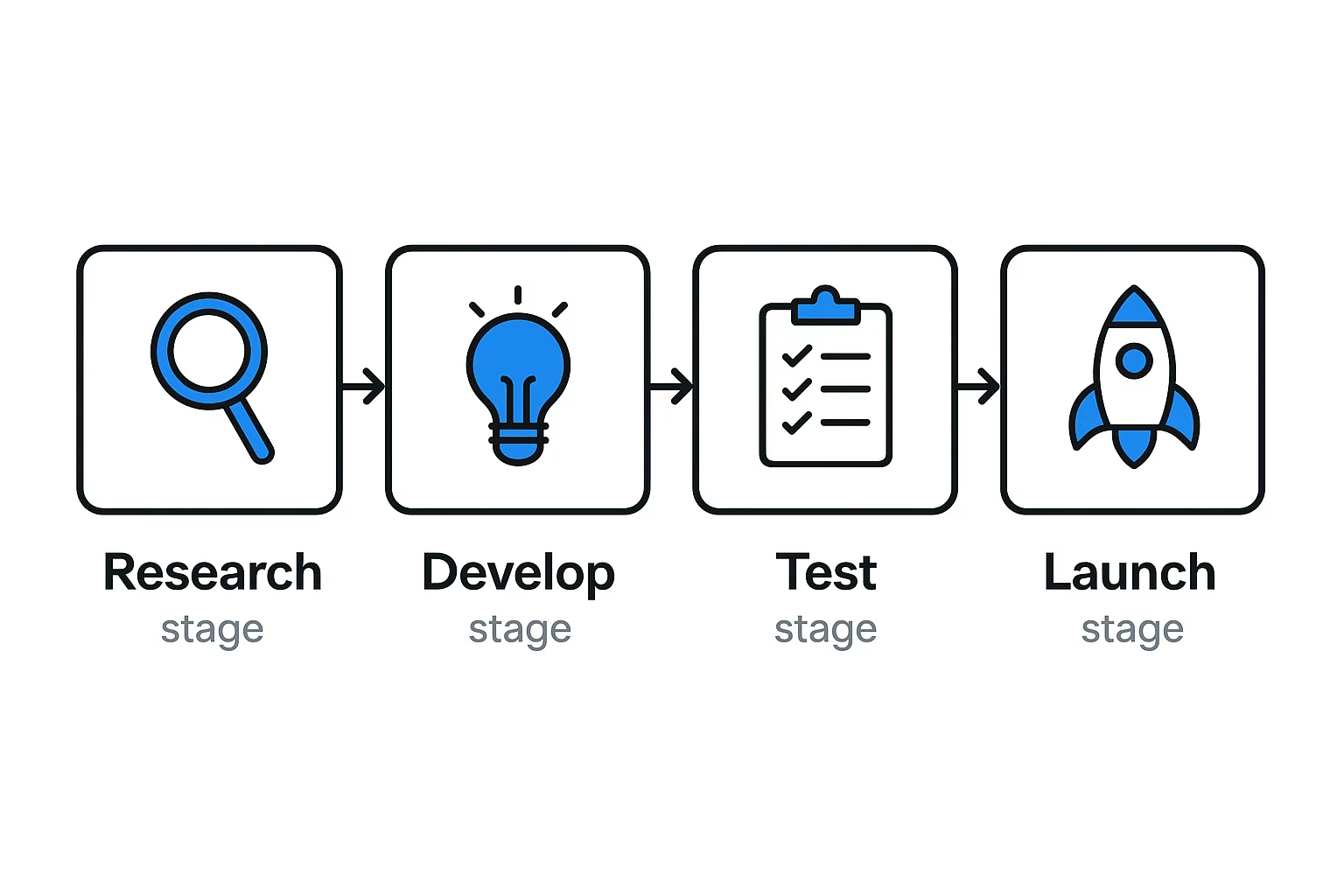

Building this into your solar module manufacturing business plan is more straightforward than it sounds. You can start with a simple, three-step approach:

-

Establish a Baseline: Create your primary financial projection using current, verifiable market prices for all key materials. This serves as your ‘Most Likely’ scenario.

-

Define Scenarios: Research the historical price range for each key material over the past 3-5 years. Use this data to create ‘Best Case’ (e.g., historical lows) and ‘Worst Case’ (e.g., historical highs) price points. For instance, if polysilicon has fluctuated between $15/kg and $40/kg, these could serve as your outer bands.

-

Analyze the Impact: Create separate versions of your profit and loss statement for each scenario. This will clearly show how your gross margin, break-even point, and overall profitability change under different market conditions.

This process transforms your business plan from a static document into a strategic guide. It prepares you for conversations with investors and lenders by demonstrating a comprehensive understanding of the market risks.

Why This Matters for Your Long-Term Success

A business plan that accounts for price volatility is more than just an impressive document; it’s a practical tool that directly informs your business strategy.

-

Securing Financing: Banks and investors are far more likely to fund a project whose founders can demonstrate they have anticipated and planned for market risks.

-

Informing Purchasing Strategy: Understanding price sensitivities helps you decide when to secure long-term supply contracts versus when to buy on the more volatile spot market.

-

Setting Realistic Prices: Your model will help you establish a pricing strategy for your modules that ensures profitability even if material costs rise unexpectedly.

Ultimately, this level of detailed planning is fundamental to every aspect of a turnkey factory setup, ensuring the technical solution is built on a sound and sustainable financial foundation.

Frequently Asked Questions (FAQ)

How much of a module’s final cost comes from raw materials?

This can vary based on technology and market conditions, but raw materials typically account for 60-75% of a solar module’s total manufacturing cost. This is why modeling their price volatility is so critical.

Can I lock in raw material prices with long-term contracts?

Yes, long-term supply agreements are possible, especially for high-volume operations. However, they require careful negotiation and come with their own trade-offs. You might secure price stability but miss out on potential savings if the market price drops. A balanced approach often works best.

Besides price, what other raw material risks should I consider?

Beyond price volatility, you should also plan for potential supply chain disruptions, logistical delays, and variations in material quality. Building relationships with multiple reliable suppliers is a key risk-mitigation strategy.

Does J.v.G. assist with this type of financial modeling?

While we are engineers, not financial advisors, our 25+ years of experience setting up production lines worldwide has given us deep insight into real-world operational costs. We guide our partners by providing the realistic data and industry context needed to build a robust and credible business plan.

Building a robust financial forecast is a critical first step toward launching a successful solar module factory. A model that honestly assesses risk is a sign of strength and prepares you for the realities of the global market.

We have guided entrepreneurs through this process for over two decades. If you are ready to move from concept to a concrete plan, we are here to provide the engineering expertise and industry experience you need.

Contact us to discuss the specifics of your project.