When investing in a solar module factory, the most important question isn’t about today’s production capacity, but tomorrow’s relevance. The solar industry evolves at a breakneck pace, and a factory designed only for current technology risks becoming obsolete within just a few years. A truly successful investment is one built for the future.

This guide offers a framework for planning a manufacturing facility that is not only profitable from day one but also engineered to adapt, scale, and lead the market for years to come. We’ll move beyond simple equipment lists to explore the strategic decisions that safeguard your long-term capital investment.

The Modern Solar Factory: Beyond Manufacturing to Strategic Investment

The most competitive solar factories today are sophisticated industrial assets—not just assembly lines, but integrated systems where automation, data, and strategic foresight create a decisive advantage. These modern facilities leverage AI, IoT, and robotics for superior quality control, predictive maintenance, and operational efficiency.

Designing your factory with this philosophy is the first step toward future-proofing. This approach ensures your production line delivers the highest quality from the start and has the digital backbone to incorporate future innovations.

The Core Decision: Your Technology Roadmap (PERC vs. TOPCon vs. HJT)

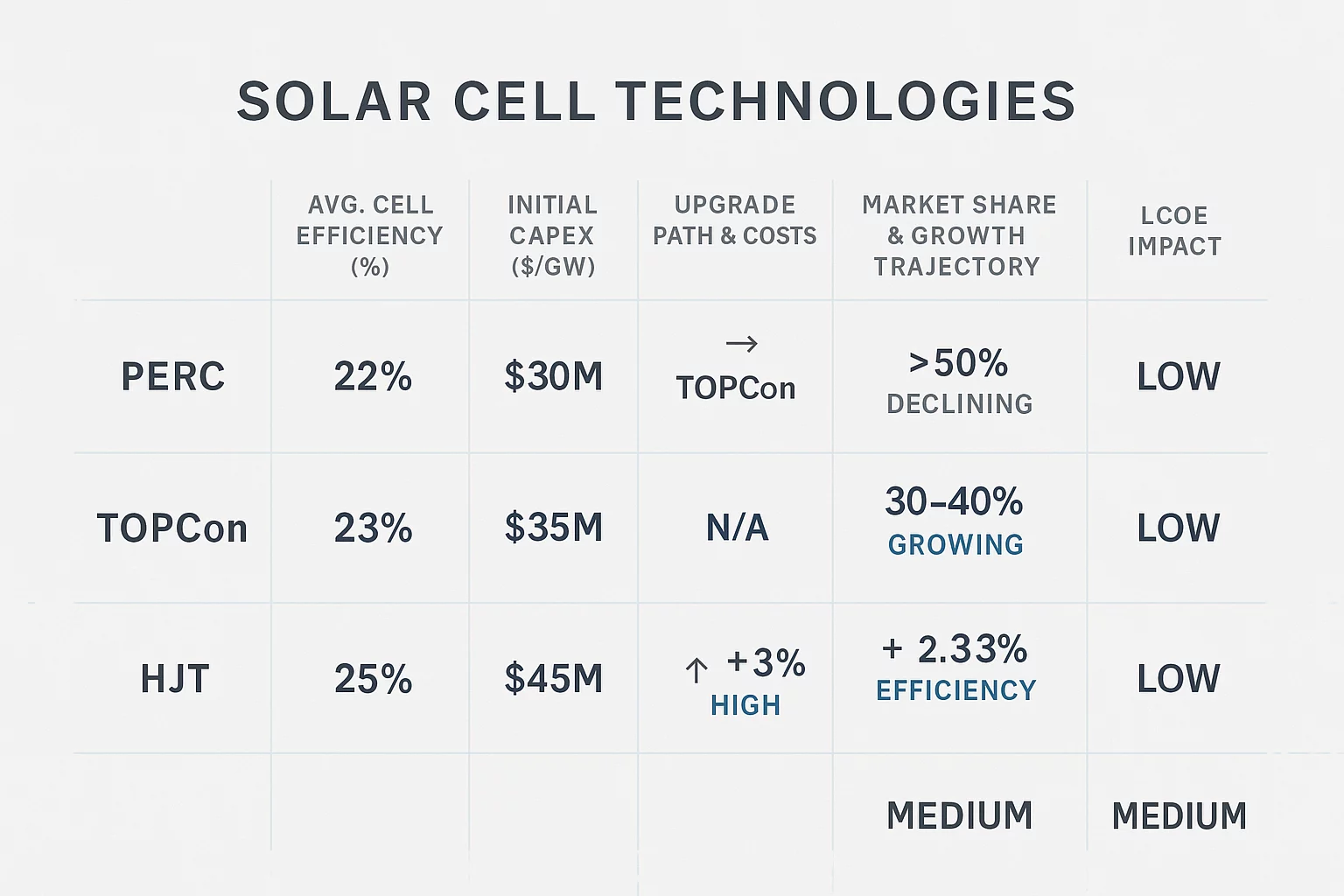

Your choice of cell technology is the most critical decision you’ll make. It directly impacts your initial capital expenditure, product competitiveness, and ability to upgrade in the future. While PERC technology has been the industry standard, the market is shifting rapidly.

According to industry analysis from PV-Tech, TOPCon technology is projected to surpass PERC in annual production by 2025-2026, driven by its tangible 1-2% energy yield advantage and superior performance.

Understanding these strategic differences is key to a wise investment.

PERC (Passivated Emitter and Rear Cell)

The established standard. Reliable and cost-effective, but its efficiency is approaching its physical limits.

TOPCon (Tunnel Oxide Passivated Contact)

The immediate successor. A key advantage of TOPCon is that it can be adopted by retrofitting existing PERC production lines, offering a highly capital-efficient upgrade path.

HJT (Heterojunction Technology)

A high-performance technology with significant efficiency potential. However, moving from PERC or TOPCon to HJT requires entirely new production lines, representing a much higher capital investment.

For new investors, this points toward a clear strategic path. Starting with a production line that is either TOPCon-ready or can be easily upgraded from PERC to TOPCon offers the best balance of initial investment, market competitiveness, and future flexibility.

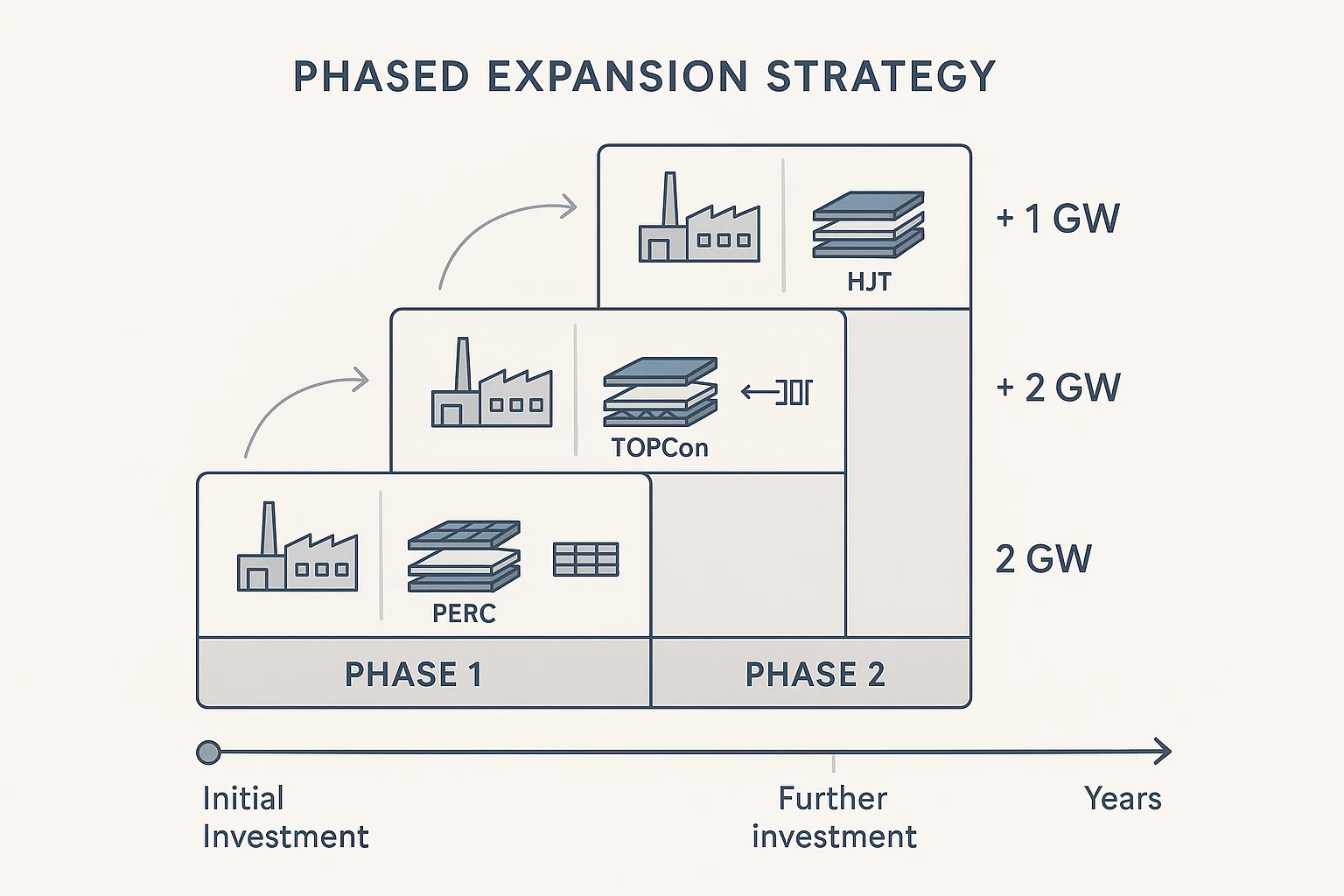

Designing for Growth: The Scalable Factory Blueprint

A common mistake is designing a factory for maximum initial capacity, leaving no room for growth. Instead, a future-proof facility is built on a modular blueprint designed for phased expansion. This approach allows you to enter the market with a manageable initial investment and scale your operations as your market share grows.

Key principles of a scalable factory blueprint include:

-

Modular Production Lines: Designing lines as self-contained modules that can be duplicated without disrupting existing operations.

-

Logical Facility Layout: Planning the physical space from day one to accommodate additional lines, warehousing, and logistics.

-

Utility and Infrastructure Planning: Sizing foundational infrastructure like electrical systems and gas lines to handle future capacity, avoiding costly retrofits down the road.

This strategy of planned expansion significantly de-risks the investment, aligning your capital outlay with revenue growth and ensuring you can respond to rising demand without a complete factory overhaul.

Financial Modeling for a Future-Proof Facility

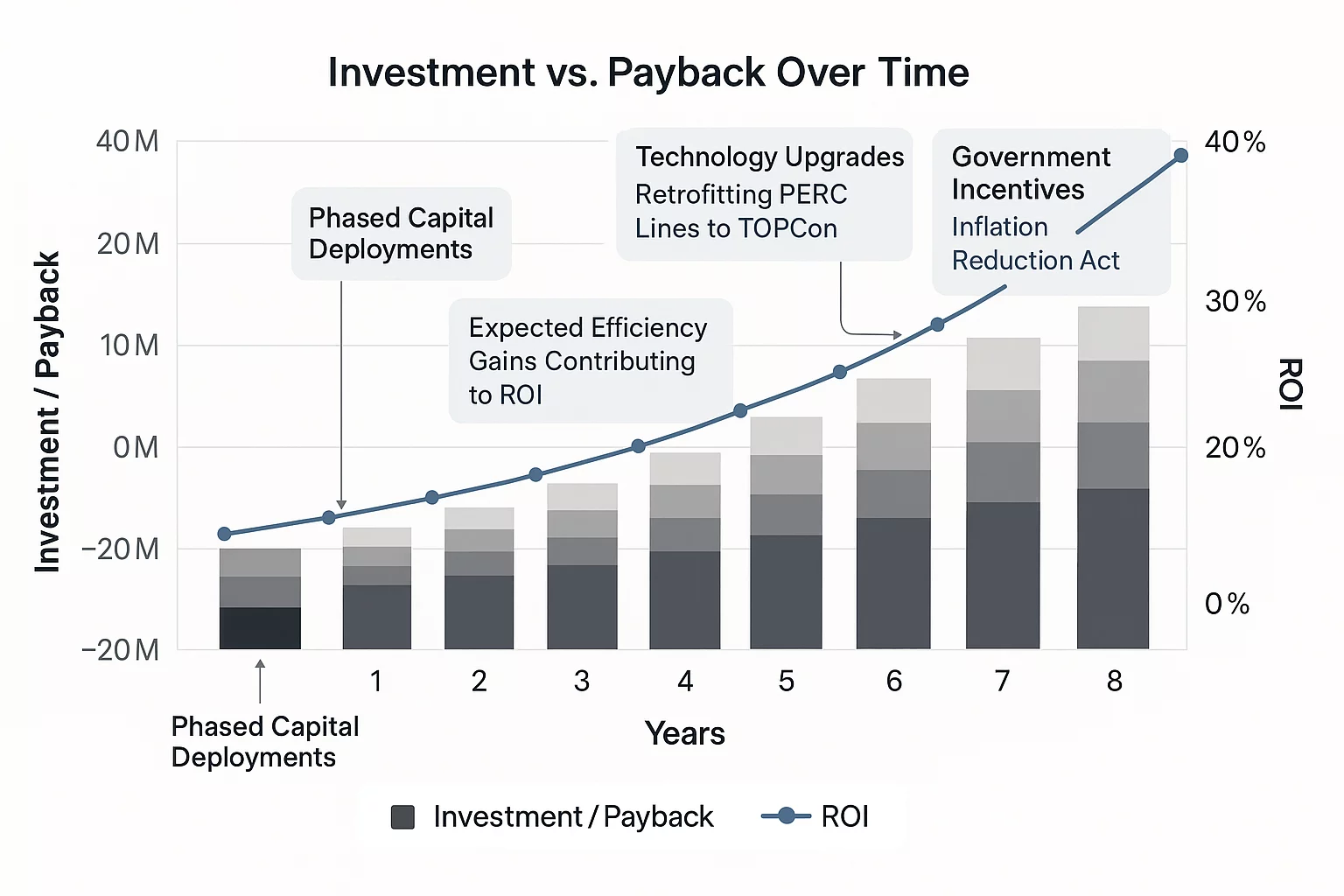

Your financial model should account for more than just the initial setup cost. A forward-looking business case also incorporates the long-term value of scalability and technology upgrades.

When modeling your project, key inputs should include:

-

Initial CAPEX: Based on your chosen starting technology (e.g., PERC with a planned TOPCon upgrade).

-

Phased Investment Tranches: Modeling the cost of adding new lines over a 3-5 year horizon.

-

Projected Upgrade Costs: Budgeting for the transition to next-generation technology.

-

Impact on LCOE: Calculating how efficiency gains from technology upgrades will lower the Levelized Cost of Energy for your customers, enhancing your competitiveness.

By planning for these future events, you’ll present a much more robust and credible business case to stakeholders and lenders. You aren’t just building a factory; you’re executing a multi-stage industrial strategy.

Frequently Asked Questions

Isn’t it safer to wait for the next dominant technology before investing?

The solar market moves quickly; waiting often means losing crucial first-mover advantage and market share. The most effective strategy isn’t to wait, but to build with a clear and cost-effective upgrade path in mind, like the proven transition from PERC to TOPCon. This allows you to enter the market now and adapt as technology evolves.

How much more does a scalable, modular design cost upfront?

While a modular layout may require a modest initial premium, this cost is significantly less than a major factory overhaul or the construction of a new facility later on. It’s best viewed as an insurance policy on your primary investment, designed to protect and enhance future revenue streams.

What if we build for TOPCon and another technology becomes the standard?

This possibility is precisely why a long-term roadmap and modular design are so important. A well-designed facility considers not just the immediate next step but also potential future shifts. While a transition to a technology like HJT would require more significant changes, a modular factory layout simplifies replacing specific line segments, containing costs and minimizing downtime compared to a rigid, monolithic factory design.

Your Partner for a Long-Term Vision

Building a solar factory is a complex undertaking. Success depends on choosing a partner who understands not only today’s technology but also the strategic path to sustained profitability. Your vision deserves an execution plan built to last.

We’ve supported entrepreneurs and investors across the globe in building state-of-the-art facilities designed for the future. Ready to discuss a clear, reliable roadmap for your project? Contact us to start planning your success.